RSJPCBA places a strong emphasis on quality throughout its PCB and PCBA processes. With a dedicated focus on precision and reliability, the company ensures top-tier results in every product. RSJPCBA’s skilled team utilizes advanced tools and cutting-edge techniques to achieve outstanding outcomes. By prioritizing innovative design and development, RSJPCBA effectively addresses the diverse requirements of its global clientele. This unwavering dedication to excellence has solidified RSJPCBA’s reputation as a reliable leader in the electronics manufacturing industry.

Key Takeaways

RSJPCBA ensures quality by using modern tools and methods for PCBs.

They listen to clients and make custom solutions to meet needs.

Following strict rules and certifications keeps their products top quality.

Careful testing and checks make sure every product works well.

RSJPCBA’s focus on new ideas helps clients sell faster and cheaper.

RSJPCBA’s Quality Philosophy

Commitment to Excellence

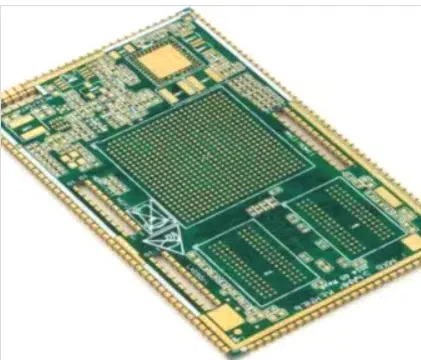

RSJPCBA demonstrates an unwavering commitment to excellence in every aspect of its operations. The company prioritizes delivering high-quality pcbas by leveraging advanced pcb design skills and technical expertise. Its team of skilled professionals ensures that every pcb and pcba meets stringent quality standards. By focusing on precision and innovation, RSJPCBA consistently produces reliable and efficient products. The company’s attention to detail and dedication to continuous improvement reflect its pursuit of perfection. This approach enables RSJPCBA to maintain its position as a trusted leader in the electronics manufacturing industry.

Client-Centric Solutions

RSJPCBA places clients at the center of its operations. The company tailors its pcb and pcba solutions to meet the unique needs of each customer. Its pcb layout designers collaborate closely with clients to create customized designs that align with specific requirements. This client-focused approach ensures that every project receives the attention it deserves. RSJPCBA’s ability to work as a team allows it to deliver solutions that exceed expectations. By fostering strong partnerships, the company builds long-term relationships based on trust and mutual success.

Industry Standards and Certifications

RSJPCBA adheres to the highest industry standards to ensure the quality and reliability of its products. The company complies with internationally recognized certifications, which validate its commitment to excellence. These certifications demonstrate RSJPCBA’s dedication to maintaining rigorous quality control measures throughout the pcb and pcba processes. By aligning with industry benchmarks, RSJPCBA guarantees that its products meet or exceed client expectations. This adherence to standards reinforces the company’s reputation for delivering high-quality pcbas and reliable solutions.

Key Steps in PCB and PCBA Processes

PCB Design and Prototyping

RSJPCBA employs a meticulous approach to the pcb design process, ensuring precision and functionality in every project. The process begins with schematic development, where the circuit design is conceptualized. This is followed by schematic capture and synchronization, ensuring seamless integration between the schematic and pcb layout. The team then focuses on pcb stackup design, defining the layers and materials for optimal performance. Design rules are established to guide the pcba design process, ensuring compliance with quality standards. Components are strategically placed, drill holes are inserted, and trace routing is performed to create efficient connections. Labeling and identification are added for clarity, and the final design files are generated for manufacturing. This comprehensive process reflects RSJPCBA’s advanced pcb design skills and commitment to quality.

Component Sourcing and Selection

RSJPCBA prioritizes sourcing high-quality components to ensure the reliability of its printed circuit boards. The company collaborates with trusted suppliers to procure components that meet stringent quality standards. Each component undergoes rigorous inspection to verify its compatibility with the pcb layout. By selecting components that align with the circuit design, RSJPCBA ensures optimal performance and durability. This careful sourcing process minimizes the risk of defects and enhances the overall efficiency of the pcba manufacturing processes.

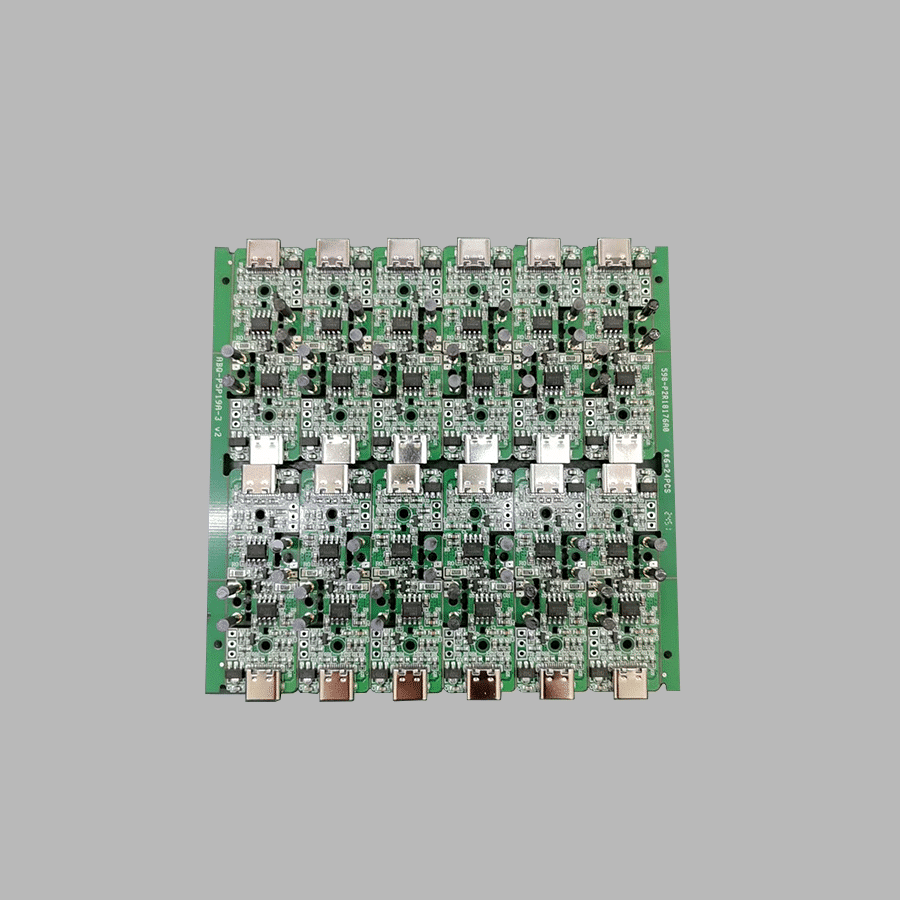

Assembly and Manufacturing

RSJPCBA utilizes advanced techniques to streamline the assembly and manufacturing of pcba. Surface Mount Technology (SMT) enables precise placement of components on the pcb surface, enhancing efficiency and accuracy. The pick-and-place process, powered by automated machines, ensures accurate positioning of even the smallest components. Automated quality control systems inspect and test soldered components, guaranteeing adherence to quality standards. These cutting-edge methods, combined with RSJPCBA’s expertise, result in reliable and high-performing pcba products. The company’s dedication to innovation and quality in manufacturing solidifies its reputation as a leader in the industry.

Final Inspection and Delivery

RSJPCBA ensures that every pcb and pcba undergoes a rigorous final inspection before delivery. This step guarantees that the printed circuit board assemblies meet the highest quality standards and function as intended. The company employs advanced testing technologies to verify the performance and reliability of each product.

The inspection process begins with a thorough visual examination. Technicians check for physical defects, such as misaligned components or soldering issues. Automated Optical Inspection (AOI) systems further enhance this process by identifying even the smallest inconsistencies. Functional testing follows, where each pcb and pcba is evaluated under real-world conditions. This ensures that the products perform reliably in their intended applications.

RSJPCBA also conducts environmental stress tests to assess the durability of its products. These tests simulate extreme conditions, such as temperature fluctuations and humidity, to confirm the resilience of the pcba. By addressing potential vulnerabilities, the company ensures long-term reliability.

Once the inspection phase is complete, RSJPCBA focuses on efficient and secure delivery. The company packages each pcb and pcba with care to prevent damage during transit. It collaborates with trusted logistics partners to ensure timely delivery to clients worldwide. This meticulous approach reflects RSJPCBA’s dedication to quality and customer satisfaction.

RSJPCBA’s final inspection and delivery processes exemplify its commitment to excellence. By combining advanced technologies with a client-focused approach, the company consistently delivers high-quality products that meet or exceed expectations.

Advanced Technologies and Tools

Design Software and Simulation

RSJPCBA employs advanced pcb design software to ensure precision and efficiency in its processes. These tools enable the team to create detailed pcb layouts that meet the highest quality standards. Simulation capabilities allow the company to test circuit designs virtually before moving to fabrication. This proactive approach minimizes errors and ensures that the final product aligns with client specifications. By leveraging cutting-edge software, RSJPCBA enhances its technical skills and delivers reliable pcba solutions.

The pcb layout designer team uses these tools to optimize the placement of components and ensure seamless integration. This meticulous attention to detail reflects RSJPCBA’s commitment to quality and innovation. The use of simulation further strengthens the design process by identifying potential issues early, saving time and resources during manufacturing.

Automated Assembly Equipment

RSJPCBA integrates state-of-the-art automated assembly equipment into its manufacturing processes. This technology ensures precision and consistency in every pcba. Surface Mount Technology (SMT) machines place components with exceptional accuracy, reducing the risk of defects. Automated soldering systems enhance the reliability of connections, ensuring that each pcb performs as intended.

The company’s investment in automation streamlines production and maintains high-quality standards. These machines handle complex layouts with ease, allowing RSJPCBA to meet the demands of various industries. By combining advanced equipment with the team’s technical skills, RSJPCBA delivers pcba products that exceed client expectations.

Testing and Inspection Technologies

RSJPCBA employs a comprehensive range of testing and inspection technologies to guarantee product reliability. These methods ensure that every pcba meets stringent quality requirements. The table below highlights the key testing techniques used by RSJPCBA:

Testing Method | Description |

|---|---|

In-circuit testing | Fast and efficient method using fixtures to test specific features on the board. |

Fixtureless In-circuit testing | Customizable but slower method using test pins to hit certain points on the board. |

Functional circuit testing | Ensures the entire PCBA performs as intended, typically at the end of the manufacturing process. |

Boundary scan testing | Tests wire lines on a PCBA when in-circuit or fixtureless testing is not possible, useful for high-density PCBAs. |

Visual or microscope-based inspection | Involves human inspection of PCBAs, either visually or with a microscope. |

X-Ray inspection | Detects defects like solder shorts that are not visible through standard inspection methods. |

Automated Optical Inspection (AOI) | Compares images of PCBAs to ideal configurations to identify defects. |

DRC checks | Ensures schematics are viable for manufacturing, preventing unfeasible designs. |

These technologies, combined with RSJPCBA’s expertise, ensure that every pcb and pcba meets the highest industry standards. The company’s dedication to thorough testing reflects its commitment to delivering reliable and high-quality products.

Quality Control Measures

Incoming Material Inspection

RSJPCBA begins its quality assurance process with a thorough inspection of incoming materials. Every component undergoes a detailed evaluation to ensure it meets the required specifications. The team verifies the compatibility of each part with the pcb design. This step prevents potential issues during the manufacturing process. Advanced tools and precise measurement techniques help identify defects or inconsistencies in raw materials. By maintaining strict control over material quality, RSJPCBA ensures that every pcb and pcba starts with a solid foundation.

The company collaborates with trusted suppliers to source high-quality components. Each supplier is evaluated based on their ability to meet RSJPCBA’s stringent standards. This proactive approach minimizes risks and enhances the reliability of the final product. Incoming material inspection reflects RSJPCBA’s commitment to delivering exceptional results.

In-Process Quality Checks

RSJPCBA implements rigorous in-process quality checks during manufacturing. These checks monitor every stage of the pcb and pcba production process. Automated systems and skilled technicians work together to identify and address issues in real time. This ensures that errors are corrected before they affect the final product.

Key checkpoints include soldering accuracy, component placement, and alignment with the pcb design. Advanced technologies, such as Automated Optical Inspection (AOI), enhance the precision of these checks. RSJPCBA’s focus on in-process quality control demonstrates its dedication to maintaining high standards throughout manufacturing.

Functional Testing and Reliability

RSJPCBA conducts comprehensive functional testing to verify the performance and reliability of its pcbas. This step ensures that each product operates as intended under real-world conditions. The team uses advanced pcba testing methods to evaluate circuit functionality and durability.

Environmental stress tests simulate extreme conditions, such as temperature changes and humidity, to assess product resilience. These tests confirm that the pcba can withstand challenging environments. RSJPCBA’s emphasis on functional testing highlights its commitment to delivering reliable and high-performing products.

RSJPCBA’s quality control measures reflect its expertise and dedication to excellence. By combining advanced skills with innovative techniques, the company ensures that every pcb and pcba meets the highest industry standards.

Compliance with Standards

RSJPCBA adheres to globally recognized standards to ensure the highest level of quality in its PCB and PCBA processes. The company aligns its operations with certifications such as ISO 9001, IPC-A-610, and RoHS compliance. These certifications validate RSJPCBA’s commitment to delivering products that meet stringent industry requirements.

The team at RSJPCBA follows a structured approach to maintain compliance. Each stage of the manufacturing process undergoes thorough documentation and review. This ensures that every product aligns with the required specifications. By adhering to these standards, RSJPCBA guarantees consistency and reliability in its offerings.

Environmental responsibility also plays a significant role in RSJPCBA’s operations. The company complies with RoHS (Restriction of Hazardous Substances) directives, ensuring that its products are free from harmful materials. This commitment not only enhances product safety but also reflects RSJPCBA’s dedication to sustainable practices.

RSJPCBA’s compliance efforts extend to its testing and inspection processes. The company employs advanced technologies to verify that each PCB and PCBA meets regulatory standards. Automated Optical Inspection (AOI) and X-ray inspection are integral to this process. These methods ensure that every product adheres to the highest quality benchmarks.

By maintaining strict compliance with industry standards, RSJPCBA reinforces its reputation as a trusted leader in the electronics manufacturing sector. This dedication to quality ensures that clients receive reliable and high-performing products tailored to their needs.

Benefits to Clients

Enhanced Product Reliability

RSJPCBA ensures that every pcb and pcba delivers exceptional reliability. The company’s rigorous quality control measures and advanced pcba testing methods guarantee that each product performs as intended. By utilizing high-quality components and precise manufacturing processes, RSJPCBA minimizes the risk of defects. The team’s expertise in pcb design further enhances product durability, ensuring that the final assemblies can withstand demanding conditions. Clients benefit from products that consistently meet or exceed their expectations, reducing the likelihood of failures in real-world applications.

Faster Time-to-Market

RSJPCBA’s streamlined manufacturing processes enable clients to bring their products to market quickly. The company’s efficient pcb design and assembly workflows reduce production time without compromising quality. Advanced automation technologies, such as surface mount technology, accelerate the manufacturing process. RSJPCBA also prioritizes clear communication and collaboration with clients, ensuring that projects stay on schedule. This focus on efficiency allows businesses to meet tight deadlines and gain a competitive edge in their industries.

Cost-Effective Solutions

RSJPCBA provides cost-effective solutions by optimizing every stage of the pcb and pcba manufacturing process. The company’s ability to source high-quality components at competitive prices helps clients save on material costs. Automated assembly equipment reduces labor expenses while maintaining precision and consistency. RSJPCBA’s expertise in pcb design minimizes errors, lowering the need for costly rework. These factors, combined with the company’s commitment to quality, ensure that clients receive reliable products at an affordable price.

RSJPCBA’s dedication to reliability, efficiency, and affordability makes it a trusted partner for businesses seeking high-quality pcb and pcba solutions.

Long-Term Partnerships

RSJPCBA values long-term partnerships as a cornerstone of its business philosophy. The company builds enduring relationships by delivering consistent quality and reliability in every pcb and pcba project. Clients trust RSJPCBA because of its commitment to excellence and its ability to adapt to evolving needs.

Collaboration plays a vital role in fostering these partnerships. RSJPCBA works closely with clients during every stage of the pcb and pcba processes. From initial design consultations to final product delivery, the company ensures open communication and transparency. This approach allows clients to feel confident in the progress and outcomes of their projects.

RSJPCBA also invests in understanding the unique challenges and goals of each client. By tailoring its pcb and pcba solutions to specific requirements, the company demonstrates its dedication to client success. This personalized approach not only enhances the quality of the final product but also strengthens the bond between RSJPCBA and its clients.

The company’s emphasis on continuous improvement further solidifies these partnerships. RSJPCBA regularly updates its design techniques, manufacturing processes, and testing methods to stay ahead of industry trends. This proactive approach ensures that clients receive cutting-edge solutions that meet the highest quality standards.

RSJPCBA’s long-term partnerships are built on a foundation of trust, collaboration, and innovation. By consistently exceeding expectations, the company establishes itself as a reliable partner in the electronics manufacturing industry.

RSJPCBA’s dedication to quality assurance in PCB and PCBA processes ensures exceptional results for its clients. The company employs advanced techniques like DRC checks to prevent unfeasible designs and automation to reduce human error. Its quality control systems resolve issues quickly while providing valuable data to minimize defects. By designing resilient PCBA solutions and incorporating thorough testing, RSJPCBA guarantees reliable and high-performing products.

Clients benefit from RSJPCBA’s focus on precision, efficiency, and innovation. The company’s streamlined processes enhance productivity and reduce time-to-market. Businesses can trust RSJPCBA to deliver cost-effective solutions tailored to their needs. Exploring RSJPCBA’s services opens opportunities for long-term partnerships and superior electronic manufacturing solutions.

RSJPCBA combines expertise, advanced technology, and a client-centric approach to deliver unparalleled PCB and PCBA solutions. Discover how RSJPCBA can elevate your next project.

FAQ

What industries benefit from RSJPCBA’s PCB and PCBA solutions?

RSJPCBA serves industries such as automotive, telecommunications, healthcare, and consumer electronics. Its expertise in PCB and PCBA processes ensures reliable and high-performing solutions tailored to diverse industry needs.

How does RSJPCBA ensure product reliability?

RSJPCBA employs rigorous quality control measures, including in-process checks and functional testing. Advanced technologies like Automated Optical Inspection (AOI) and environmental stress tests verify product performance and durability.

Can RSJPCBA handle custom PCB and PCBA designs?

Yes, RSJPCBA specializes in custom PCB and PCBA designs. Its team collaborates closely with clients to create tailored solutions that meet specific requirements while maintaining high-quality standards.

What certifications does RSJPCBA hold?

RSJPCBA complies with globally recognized certifications, including ISO 9001, IPC-A-610, and RoHS. These certifications validate its commitment to quality, safety, and environmental responsibility.

Why choose RSJPCBA for PCB and PCBA manufacturing?

RSJPCBA combines advanced technology, skilled expertise, and a client-centric approach. Its streamlined processes ensure precision, efficiency, and cost-effectiveness, making it a trusted partner for PCB and PCBA solutions.