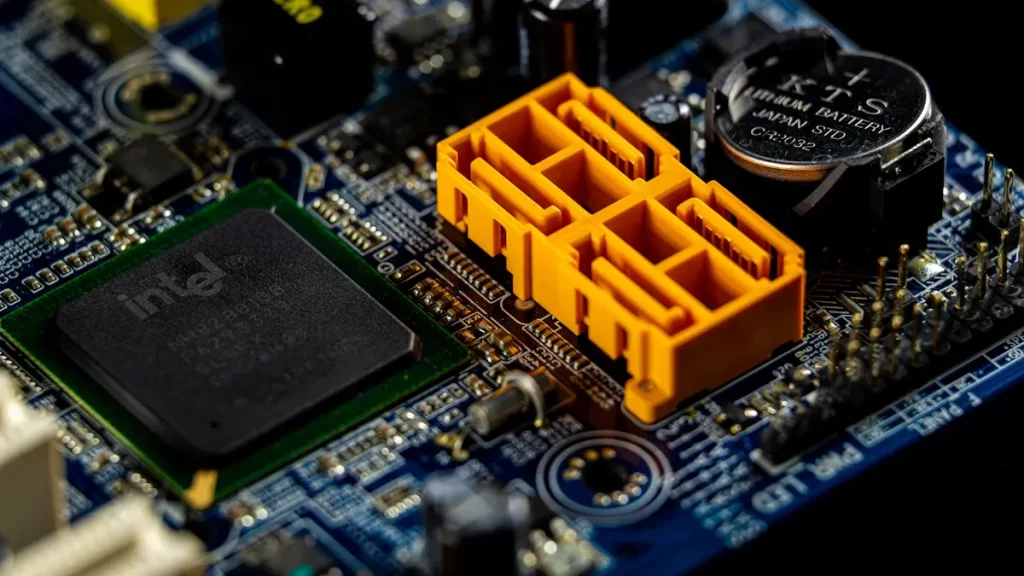

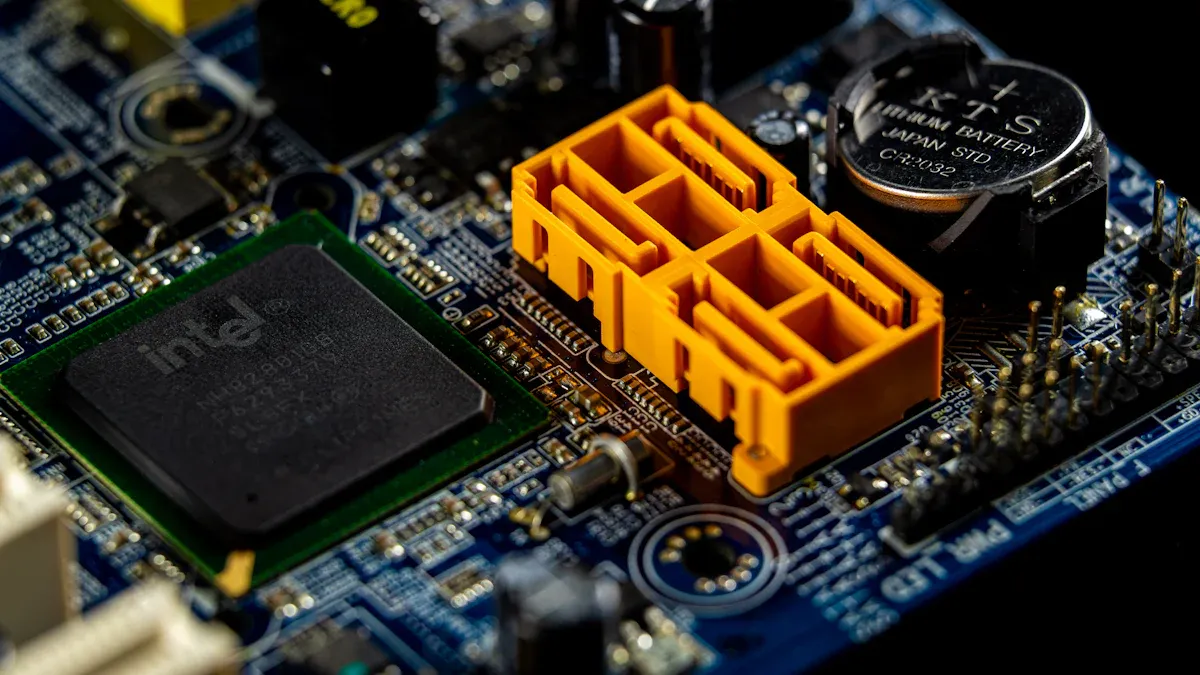

Designing high-quality ITAR compliant PCB assembly for industrial IoT circuit boards for aerospace requires adherence to strict rules. These devices operate in critical environments where failure is not an option. Standards such as IPC Class 3A, MIL specs, and AS9001 ensure their robustness. Additionally, EMC and CISPR regulations help mitigate electromagnetic interference. Compliance with these standards ensures that devices remain safe and function effectively for defense applications.

Creating ITAR compliant PCB assembly for industrial IoT boards safeguards sensitive technology. Designers must account for extreme environmental conditions, durability, and secure data handling to fulfill the stringent requirements of aerospace and defense sectors.

Key Takeaways

Follow ITAR rules to keep important technology safe and meet defense rules.

Pick strong materials and test them well to handle tough aerospace conditions.

Use good security tools, like encryption and access locks, to protect data and follow ITAR rules.

Add backup systems and safety features to make designs reliable and avoid failures.

Learn about security labels like FIPS and Common Criteria to show trust and follow rules.

ITAR Compliant PCB Assembly for Industrial IoT

Key ITAR Rules for Defense Electronics

When making ITAR-compliant PCBs for industrial IoT, you must know the rules. ITAR, or International Traffic in Arms Regulations, controls defense exports. These rules keep sensitive tech, like navigation systems, safe. They stop such technologies from reaching unauthorized people.

The U.S. Munitions List (USML) lists items under ITAR rules. This includes military electronics like radar and avionics systems. For example, ITAR affects defense manufacturing by requiring strict records and export checks. Between 2013 and 2021, over 8,500 ITAR violations were reported. This shows how important it is to follow these rules.

Regulation | What It Does |

|---|---|

ITAR Compliance | Controls defense exports and related technical data. |

USML Categories | Lists items under ITAR, including military electronics. |

By following ITAR, you can protect sensitive tech and stay compliant.

Steps to Meet ITAR Rules in PCBA

To meet ITAR rules in PCB assembly, follow these steps:

Create a program to show your ITAR commitment.

Assign a compliance officer to manage ITAR efforts.

Check your processes often and fix any problems.

Teach employees about ITAR rules and company policies.

Make sure suppliers also follow ITAR rules.

Add ITAR terms in contracts to clarify duties.

Control how technical data moves in your supply chain.

Use designs that avoid ITAR risks, like fewer controlled parts.

Limit facility access to only authorized workers.

Label and classify ITAR-controlled shipments properly.

Get export licenses before shipping controlled items.

For example, Echodyne used connected systems to meet ITAR rules. This made their processes easier and compliant. Promex uses strong security and access controls to ensure quality and compliance.

By following these steps, you can meet ITAR rules and help defense manufacturing.

Records and Security for ITAR Compliance

Good records and strong security are key for ITAR-compliant PCBs. Keep clear records and protect sensitive data. Important records include:

Record Type | What It Covers |

|---|---|

Export Control Processes | Tracks and documents export controls. |

Controlled Item Classification | Lists items under ITAR rules. |

Export Licensing | Records licenses for controlled items. |

Internal Controls | Ensures compliance with ITAR rules. |

Employee Training | Educates workers on ITAR rules. |

Data Security Measures | Protects sensitive data from unauthorized access. |

You also need strong security to protect data. This includes:

Limiting who can access sensitive information.

Using encryption to protect data during storage and sharing.

Verifying user identity before accessing ITAR data.

Setting rules for storing, sharing, and deleting data safely.

By doing this, you can follow ITAR rules and protect defense products. This not only keeps tech safe but also helps your role in defense manufacturing.

Ensuring High Reliability in Aerospace PCBAs

Material Selection for Long-Term Durability

Picking the right materials is key for durable aerospace PCBAs. These boards face tough conditions like extreme heat, pressure, and fast speed changes. Materials that resist moisture, salt, and mildew are very important. For example, strong aerospace composites and alloys are chosen for their toughness and stress resistance.

To make sure materials last, tests check how they handle harsh conditions. These tests look at corrosion, heat expansion, and wear resistance. By using materials that pass these tests, you can make reliable PCBAs for important missions.

Testing and Validation for High-Reliability Applications

Testing is needed to make sure aerospace PCBAs work well. It finds weak spots and checks if boards handle tough environments. Common tests include:

HALT checks performance in extreme conditions.

HASS finds early production problems.

Thermal shock tests check heat change resistance.

Mechanical shock tests check strength against impacts.

Testing Method | Purpose |

|---|---|

HALT | Checks board performance in extreme conditions. |

HASS | Finds early production issues. |

Thermal shock testing | Tests resistance to quick temperature changes. |

Mechanical shock testing | Checks strength against physical impacts. |

These tests make sure PCBAs meet aerospace standards and work reliably for critical tasks.

Incorporating Redundancy and Fail-Safe Mechanisms

Backup systems and safety features improve aerospace PCBA reliability. Redundancy adds extra parts, like dual power supplies, to avoid failures. This keeps systems working even if one part breaks.

Fail-safe features, like checks for errors, catch problems early. These safety steps can find and fix up to 90% of issues. Adding these features lowers failure risks and ensures aerospace PCBAs work well in important situations.

Extreme Environment Design for Aerospace IoT Devices

Keeping Devices Cool in Tough Conditions

Good cooling keeps aerospace IoT devices working in harsh places. Hot temperatures and dusty air can make cooling systems fail. You need to check temperatures and use filters to stop overheating. Cleaning filters often helps keep devices running well.

High altitudes make cooling harder because the air is thinner. Thin air cools less, so designs must change to work better. Working with engineers helps create strong designs that meet tough needs. Special computer tests check if designs can handle these hard conditions.

Important cooling tips:

Watch temperatures and clean air filters often.

Change designs for high-altitude cooling problems.

Work with experts to make strong, reliable designs.

Protecting Military Electronics from Vibrations and Shocks

Military electronics face lots of shaking and impacts. PCBs must be built to handle these without breaking. Strong mounts and shock-absorbing materials make them tougher. Tests like Environmental Stress Testing (EST) and DO-160 check if devices meet strict rules.

Test Type | What It Checks |

|---|---|

Environmental Stress Testing | Tests if devices work in tough real-world conditions. |

Pressure and Impact Resistance | Checks if devices can handle strong forces in air or underwater. |

DO-160 Testing Process | Makes sure devices work in different harsh environments. |

These tests prove devices can survive the tough demands of military systems in space.

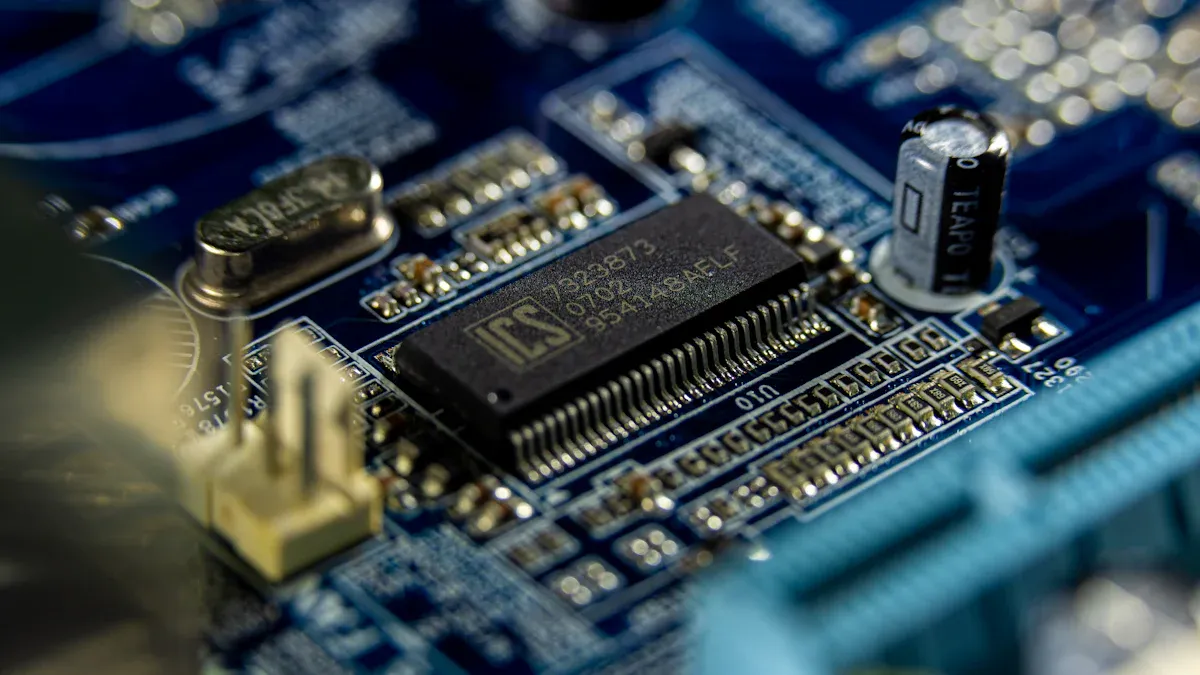

Protecting Electronics from Space Radiation

Radiation in space and high places can harm electronics. Special designs protect devices from this damage. Using radiation-safe parts, like special memory chips, keeps data safe. These designs also include cooling and strong packaging to last longer.

Satellites, space robots, and airplane systems need these designs. Careful testing makes sure they work for important missions. By focusing on radiation safety, you protect military and aerospace devices in space.

Security Certification and ITAR Compliance

Important Security Certifications for Aerospace IoT Devices

Getting security certifications proves your aerospace IoT devices are safe. Certifications like Common Criteria (CC) and FIPS show they protect sensitive data. These certifications confirm your devices can keep important information secure for national safety.

For ITAR compliance, certifications ensure your systems meet strict rules. For instance, FIPS 140-2 checks if data encryption follows government standards. CC reviews the security of your device from start to finish. Earning these certifications builds trust and shows you follow ITAR rules.

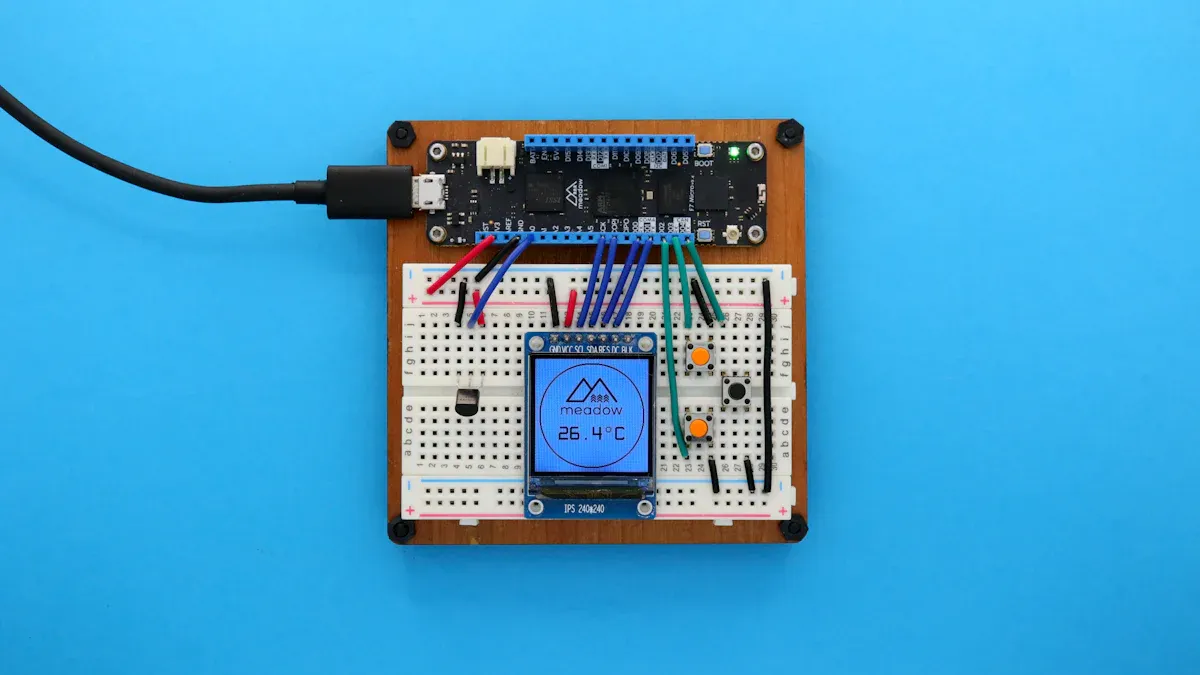

Using Secure Boot and Firmware Updates

Secure boot and firmware updates keep aerospace IoT devices safe. Secure boot checks each software layer before it runs. It starts with a protected bootloader that verifies other bootloaders using digital signatures.

Modern microcontrollers (MCUs) improve this by using encrypted firmware and rollback protection. These tools block hackers and keep systems safe. Secure boot stops harmful software and helps meet ITAR rules.

Benefits of secure boot and firmware updates:

Stop changes to firmware without permission.

Keep systems safe with digital signature checks.

Protect data using encrypted firmware files.

Keeping Data Safe and Blocking Unauthorized Access

Protecting data and controlling access are vital for ITAR-compliant devices. Strong measures are needed to stop unauthorized access to sensitive data. Encryption helps secure data during storage and sharing.

Access controls like multi-factor authentication (MFA) add extra security. These controls ensure only approved people can use sensitive systems. Regular checks and monitoring find weak spots and fix them. This keeps your devices ITAR-compliant and secure.

By focusing on data safety, you meet ITAR rules and help national security. This protects important technologies and builds trust in your aerospace IoT devices.

Encryption Requirements for ITAR Compliance

Why End-to-End Encryption Matters in Defense Systems

End-to-end encryption keeps sensitive data safe in defense systems. It ensures only approved users can see the data. This stops others from stealing or changing it during transfer. For ITAR compliance, encryption is a must to protect national security. Without strong encryption, important data could be stolen, risking critical missions.

In military IoT systems, encryption keeps data private and accurate. For instance, LoRaWAN uses a message integrity check (MIC). This stops data from being changed during transfer. It also adds security at both the network and application levels. Unique keys for each device allow only approved devices to connect. These steps make ITAR-compliant devices safer and help protect national security.

Picking the Right Encryption Protocols for IoT Devices

Choosing good encryption protocols is key for ITAR compliance. These protocols must meet strict rules to ensure strong security. Some well-known standards include:

FIPS 140-2: Sets rules for secure devices used by the U.S. government.

NIST SP 800-53: Lists controls to protect federal systems and data.

ISO/IEC 27001: Focuses on managing information security systems globally.

Think about your IoT device needs when picking protocols. Military IoT systems need strong encryption to keep data safe. Protocols like SSL/TLS secure data transfers. Over-the-Air Activation (OTAA) adds dynamic device authentication. Following these standards ensures your devices meet ITAR rules.

Managing Encryption Keys and Keeping Data Safe

Managing encryption keys well is crucial for secure ITAR systems. Poor key handling can weaken device security. Use strong protocols like SSL/TLS to protect keys during exchanges. These protocols stop data theft and keep communication secure.

Plan key storage and sharing carefully. Use tools like hardware security modules (HSMs) to create and store keys safely. Automating key updates and removal reduces mistakes. Add extra security with role-based access and multi-factor authentication.

Check key use often to find weak spots and stay compliant. Have a recovery plan for emergencies to secure backups. By following these steps, you can manage keys safely and protect ITAR-compliant systems. This keeps sensitive data secure and meets ITAR standards.

Making industrial IoT devices for aerospace needs strict PCBA rules. These include following ITAR rules, ensuring reliability, and adding strong security. Meeting these rules helps devices work well in important defense tasks.

To do this, choose tough materials, run careful tests, and add safety features. Protect data using encryption and get required certifications. By focusing on these steps, you can build devices that are safe, reliable, and meet aerospace and defense needs.

FAQ

What is ITAR compliance, and why does it matter for aerospace IoT?

ITAR compliance stops sensitive defense tech from reaching the wrong people. For aerospace IoT, it protects national security by controlling exports and handling of military electronics and technical data.

How do you make PCBA reliable in tough environments?

Choose strong materials and test them with HALT and HASS. Add backup systems to handle extreme heat, shaking, and radiation. These steps ensure PCBAs work well in aerospace conditions.

What are the main security certifications for aerospace IoT devices?

Key certifications include Common Criteria (CC) and FIPS 140-2. These prove your devices meet strict security rules, protecting data and following ITAR standards for defense systems.

Why is end-to-end encryption important for ITAR devices?

End-to-end encryption keeps data safe during transfer. Only approved users can see it, stopping hacking or changes. This helps meet ITAR rules and protects national security.

How do you keep encryption keys safe?

Use hardware security modules (HSMs) to store keys securely. Add role-based access and multi-factor authentication. Check key use often and automate updates to avoid mistakes. These steps protect ITAR-compliant systems.

See Also

Designing Energy-Efficient PCBs for Industrial IoT Solutions

The Importance of PCBA Production for IoT Devices Today

Evaluating Features of PCB Assembly for Industrial IoT Gateways