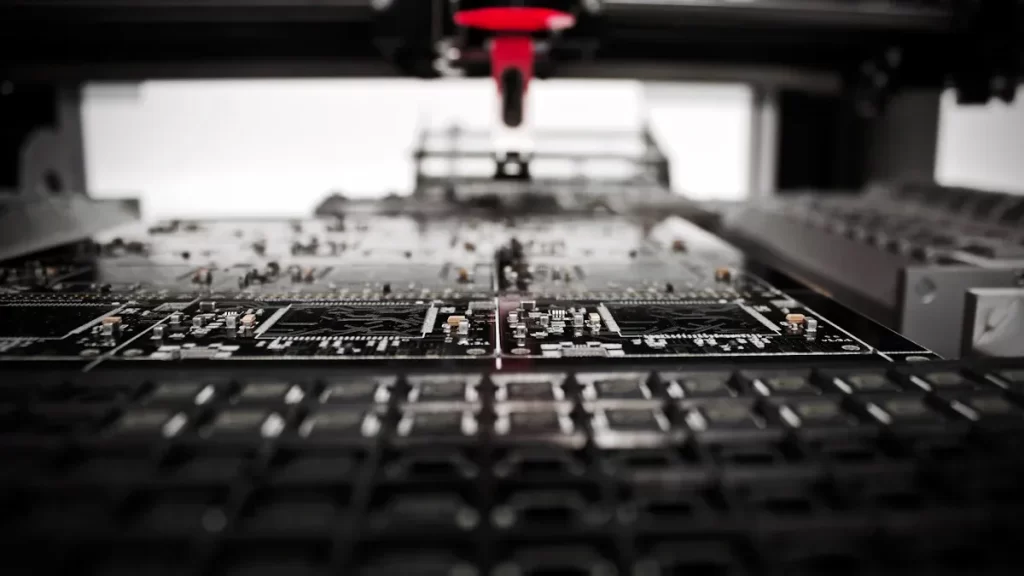

The Summit PCB for advanced PCBA manufacturing changes how circuit boards are made. It uses new technology to handle complex modern electronics. As gadgets get smaller and stronger, old methods often fail. Better solutions are needed for accuracy, speed, and dependability.

Summit Interconnect has been a top company since 2016. It works in eight places across North America with over 1,250 skilled workers. They make dense rigid boards, flexible circuits, and RF/microwave PCBs. These are perfect for important uses like aerospace and defense.

Key Takeaways

The Summit PCB uses special materials and HDI tech to make small, strong circuit boards for modern gadgets.

It improves production by working well with machines, cutting mistakes and making things faster.

The PCB handles heat well, keeping devices cool and reliable for tough jobs.

Its flexible design works for many fields like space, phones, and medical devices.

Picking The Summit PCB helps companies stay ahead and prepared for changes in the fast-moving electronics world.

Understanding The Summit PCB

What makes The Summit PCB unique

The Summit PCB is special because of its smart design and advanced features. It uses modern materials that make it strong and work better. These materials help the boards handle heat and tough conditions. You get a product that works well, even in hard situations.

Another key feature is its support for high-density interconnect (HDI) technology. This lets you make smaller and more efficient circuit boards. It keeps all the functions without losing quality. The Summit PCB also works easily with new assembly methods. This makes it a flexible choice for manufacturers like you.

Tip: Need a PCB that’s tough, precise, and flexible? The Summit PCB is a great pick.

Its role in advanced manufacturing

The Summit PCB is important for advanced manufacturing. It helps make complex electronics easier to produce. For example, it works well with automated systems, saving time and reducing mistakes. This helps you meet deadlines while keeping high quality.

It also handles heat very well, making it great for powerful devices. Whether you’re making aerospace parts or everyday gadgets, The Summit PCB keeps performance steady. Using this technology helps you stay ahead in the fast-moving world of manufacturing.

Applications in complex circuit solutions

The Summit PCB is great for solving tricky circuit problems. Its dense design supports detailed layouts, perfect for industries like telecom, medical tools, and defense. It can manage multi-layer circuits and fast data speeds.

For instance, in aerospace, The Summit PCB ensures reliable systems for communication and navigation. In medical tools, it provides accuracy, which is vital for safety. Its flexibility helps you solve many challenges, no matter how hard they are.

Note: The Summit PCB is made for today’s industries. It offers top reliability and performance.

Key Features of The Summit PCB

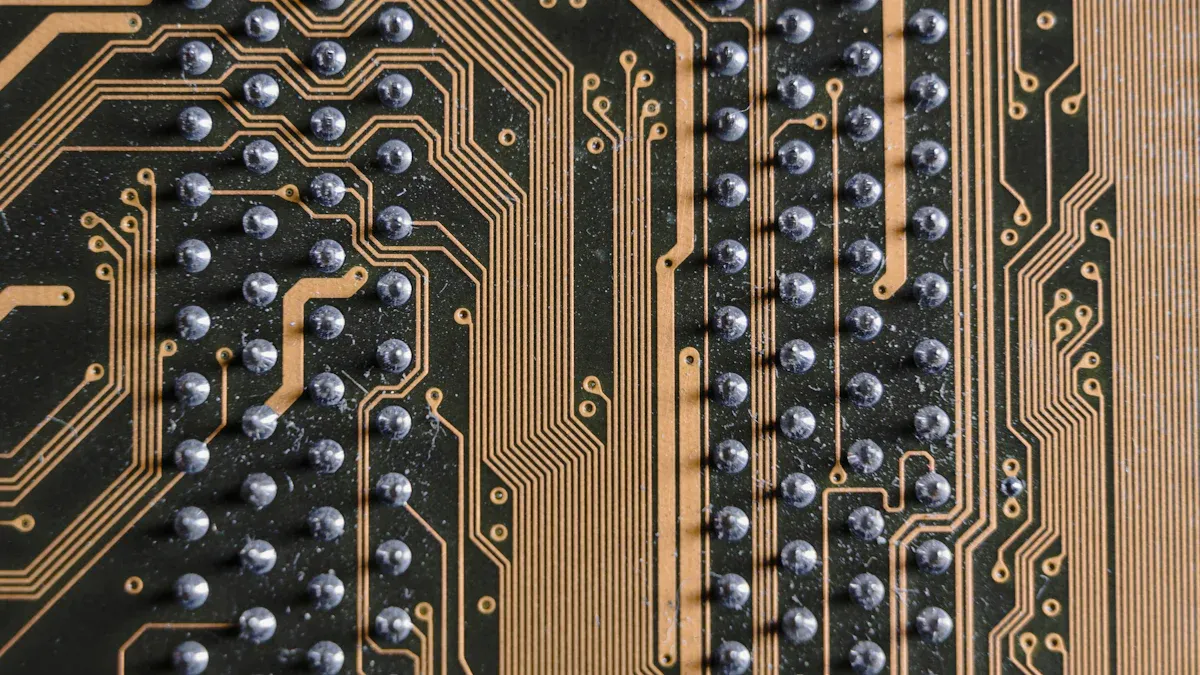

Advanced material and design capabilities

The Summit PCB is special because it uses strong materials. These materials help it last longer and work in tough places. It’s great for things like airplanes and defense tools. You get a product that stays strong and works well under stress.

Its design features are also very advanced. It can handle many layers and tight layouts for small gadgets. It keeps data moving smoothly, even in fast circuits. Special finishes, edge plating, and tiny holes like microvias make it good for tricky designs.

Here’s a simple list of its main features:

Feature | What It Does |

|---|---|

Multilayer and HDI PCB design | Helps create modern, compact electronics. |

Smooth data flow | Keeps fast circuits working without problems. |

Tiny holes like microvias | Saves space and fits more parts in small gadgets. |

Filled vias | Works well for complex digital designs. |

Edge plating and finishes | Makes it stronger and better connected. |

Eco-friendly processes | Follows rules to protect the environment. |

Fast production | Can be ready in just 24 hours for some jobs. |

High-level certifications | Ready for important jobs needing top reliability. |

These features make it a smart pick for industries needing accuracy and flexibility.

High-density interconnect (HDI) technology

HDI technology makes electronics smaller and better. The Summit PCB uses this to create tiny, powerful boards. This is perfect for phones, medical tools, and airplane systems where space is tight but performance matters.

It includes tiny holes and stacked layers for detailed designs. These let you fit more parts into less space. This means your product can be smaller but still work better.

Thermal management for high-performance applications

Keeping devices cool is very important. The Summit PCB uses special materials to spread heat evenly. This keeps gadgets from overheating, even when working hard. It’s great for flexible and rigid-flex boards where heat can cause problems.

It also has features like thermal holes and special coatings to handle heat better. Using this PCB makes your products last longer and work more reliably. This makes them more attractive to buyers.

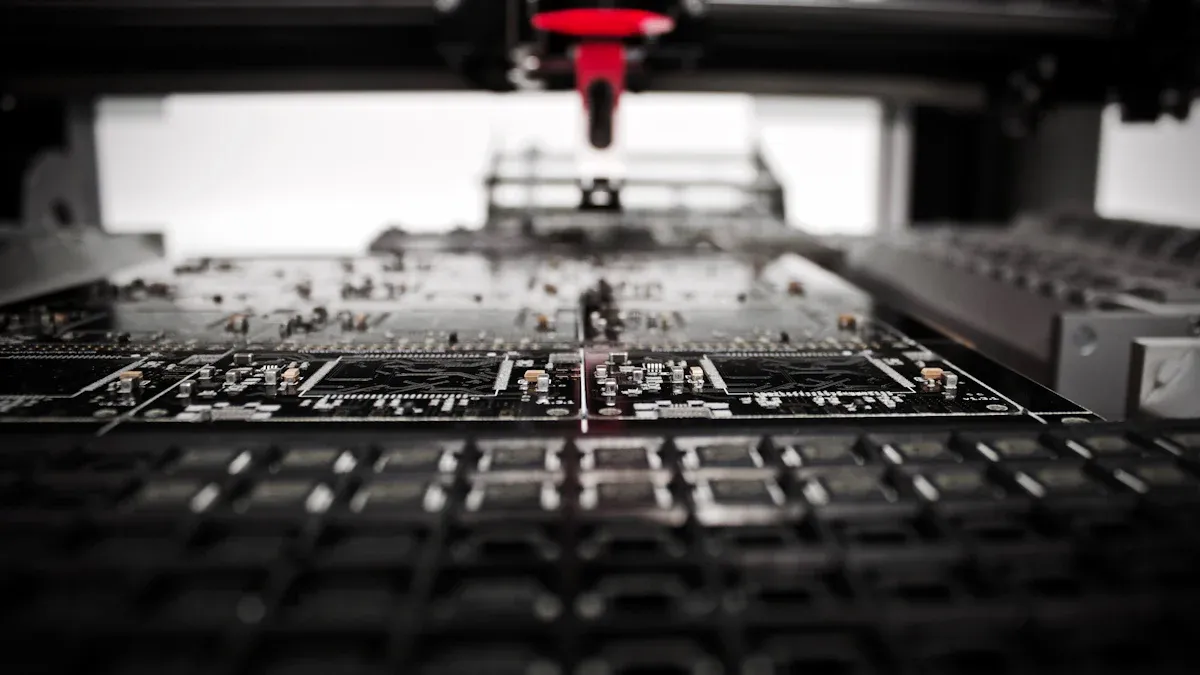

Compatibility with modern assembly techniques

The Summit PCB works well with today’s assembly methods. Manufacturers need PCBs that fit new production styles. This helps make work easier and products better.

One big plus is its support for automated assembly. Its accurate design lowers mistakes during part placement and soldering. This cuts down on manual fixes, saving time and effort. Whether using SMT or through-hole assembly, it performs reliably.

It also follows design for manufacturability rules. This means its layout makes building easier without losing quality. Features like microvias and edge plating speed up assembly. These also make the final product stronger and more dependable.

The Summit PCB handles advanced soldering methods like reflow and wave soldering. Its materials resist high heat, staying strong during these steps. This makes it great for high-performance uses needing precision.

It also works well for testing and inspections. It supports AOI and ICT to catch problems early. This ensures only top-quality products go to your customers.

Choosing The Summit PCB improves your manufacturing process. Its modern design and flexibility meet today’s tech needs. This keeps your production fast, reliable, and future-ready.

Enhancing Advanced Manufacturing with The Summit PCB

Making production faster and easier

The Summit PCB helps factories work faster and better. It uses smart tools to speed up tasks. Machines handle materials quickly, avoiding delays. Storage systems are designed to find items fast, saving time.

Modern factories use small layouts with automated machines. These setups keep production moving, even in tight spaces. Tracking systems show where materials are, helping you stay organized. Robots carry items safely, reducing worker effort and delays.

Using The Summit PCB makes production smoother and quicker. It works well with automated tools, cutting mistakes and saving time. This helps you finish jobs on schedule.

Helping with small and detailed designs

Electronics today need to be small and powerful. The Summit PCB is great for this. It uses HDI technology to make tiny boards that still work well. Small holes and stacked layers fit more parts into less space.

This is perfect for industries like telecom, airplanes, and medical tools. You can make lightweight products that save space but still perform well. Its smart design keeps data flowing smoothly, even in tricky circuits.

With The Summit PCB, you can create small, advanced designs that meet modern needs.

Making products more accurate and reliable

Accuracy is very important in electronics. The Summit PCB helps you build with fewer mistakes. Machines place parts carefully, so you don’t need to fix them by hand.

It works with inspection tools like AOI and ICT to catch problems early. This stops bad products from reaching customers. Features like edge plating and heat control make products stronger and more dependable.

The Summit PCB improves quality by reducing errors. You can make reliable products that meet high standards and keep customers happy.

Scalability for large scale PCB manufacturers

Growing your PCB production can be tough, especially with big orders. The Summit PCB helps large manufacturers handle these challenges easily. Its smart features and flexible design make scaling up simple and efficient.

Why scalability matters for large scale PCB manufacturers

Big PCB makers must handle more orders without losing quality. The Summit PCB uses advanced tech like HDI and multilayer designs. These help create detailed boards in large amounts while staying precise and reliable.

Tip: Use The Summit PCB to keep quality steady in big projects. This helps meet customer needs every time.

Features that support scalability

The Summit PCB has many features that help large-scale production:

High-speed production capabilities: It works well with automated tools, saving time and effort.

Material optimization: Strong materials lower defects, even in big batches.

Adaptability: It fits into modern production lines without trouble.

Thermal management: It spreads heat evenly, keeping devices working well.

These features make scaling up easier without losing quality or speed.

Benefits for large scale PCB suppliers

Choosing The Summit PCB gives you many benefits for scaling up:

Better production efficiency: Automation speeds up work and avoids delays.

Cost savings: Strong materials and fewer mistakes cut costs over time.

Improved reliability: Products stay consistent, building customer trust.

Flexibility: It works with different assembly methods for changing needs.

These advantages make The Summit PCB a great choice for growing PCB businesses.

Real-world applications

The Summit PCB is used in industries like aerospace, telecom, and medical tools. For example, aerospace companies trust it for making navigation systems in bulk. Telecom firms use it for small, high-performing boards in communication devices.

Using The Summit PCB helps you grow while keeping top quality for these industries.

Note: The Summit PCB grows with your business, making it a smart long-term choice for large manufacturers.

Benefits of The Summit PCB for Manufacturers

Improving production speed

The Summit PCB makes production faster and easier. Its smart design works well with automated machines. This reduces the need for fixing parts by hand. Machines place parts correctly, cutting mistakes and saving time. Faster production helps you meet deadlines without losing quality.

The Summit PCB fits perfectly with modern manufacturing methods. Whether you use surface-mount or through-hole assembly, it works smoothly. By improving your production process, you can handle more orders and make more products.

Tip: Faster production helps you take on more work and grow.

Saving money over time

Using The Summit PCB helps you save money in the long run. Its strong materials lower the chance of defects, saving repair costs. The high-quality design also reduces mistakes during assembly, wasting fewer resources.

Its heat control features keep devices from overheating. This makes your products last longer and work better. Fewer problems mean fewer returns and happier customers. Over time, these savings make The Summit PCB a smart choice for manufacturers.

Making products stronger and better

The Summit PCB makes your products more reliable. Features like HDI and heat control keep them working well, even in tough conditions. This is great for industries like aerospace, telecom, and medical tools.

With this PCB, you can make high-quality products that rarely fail. Its careful design lowers the chance of problems, giving customers trust in your brand. Reliable products improve your reputation and help you stay ahead in the market.

Note: Strong and reliable products keep customers happy and loyal.

Meeting the demands of modern electronics

Modern electronics need to be precise, reliable, and adaptable. As a maker, you must meet these needs and stay ahead. The Summit PCB helps you handle these challenges and create advanced products.

The Summit PCB works for detailed designs in today’s devices. Its high-density interconnect (HDI) technology makes small, layered boards. These boards are key for telecom, aerospace, and medical tools. You can make smaller designs that still work well.

Managing heat is very important for modern devices. Heat can hurt how gadgets perform. The Summit PCB uses special materials to spread heat evenly. This keeps your products working well, even under heavy use.

It also fits with modern assembly methods to improve production. The Summit PCB works easily with automated systems, cutting mistakes and saving time. Its smart design supports surface-mount technology (SMT) and other new methods.

Choosing The Summit PCB helps you meet modern electronics needs. Its features let you make strong, high-quality products that stand out. Whether for aerospace, telecom, or everyday gadgets, this PCB keeps you ahead.

Tip: Using The Summit PCB makes you a leader in advanced manufacturing, ready for modern challenges.

Why Choose The Summit PCB for Advanced PCBA Manufacturing

Staying competitive in the electronics industry

Electronics change quickly, so staying ahead is important. The Summit PCB uses advanced technology to meet modern needs. Features like high-density interconnect (HDI) and heat control help make small, powerful devices. These tools let you create products that are fast, reliable, and compact.

Using this PCB makes production smoother and reduces mistakes. This keeps your products high-quality, which builds trust with customers. Choosing The Summit PCB helps you lead in electronics manufacturing and handle new challenges easily.

Adapting to evolving manufacturing needs

Manufacturing keeps changing, and you must keep up. Trends like smaller designs and automation are now common. The Summit PCB works well with new methods like surface-mount technology (SMT). It fits easily into modern production setups.

This PCB handles detailed designs, perfect for aerospace, telecom, and medical tools. It supports fast data and complex layouts for advanced electronics. With The Summit PCB, you can meet today’s changing manufacturing needs confidently.

Future-proofing production capabilities

Planning for the future is key to success. The Summit PCB is strong and flexible, ready for new technology. Its durable materials keep products reliable as electronics improve.

This PCB also scales well for big orders without losing quality. Whether making a few items or many, it delivers great results. Investing in The Summit PCB prepares your business for growth and innovation.

Tip: Use The Summit PCB to stay ready for future challenges in manufacturing.

The Summit PCB is a big step forward in PCBA manufacturing. It has smart features like HDI technology and great heat control. These help you make strong and high-performing products. It also makes production faster and meets modern electronics needs easily.

When you pick The Summit PCB, you get a tool that boosts efficiency and lowers mistakes. It works well with today’s assembly methods, making it useful for factories and suppliers. See how it can improve your work and grow your business. Reach out to trusted suppliers now to learn how to use The Summit PCB in your projects.

FAQ

What industries benefit the most from The Summit PCB?

The Summit PCB is great for aerospace, telecom, and medical tools. Its HDI technology and heat control make products strong and reliable. These features help create high-quality gadgets for these industries.

Tip: Need durable and precise PCBs? The Summit PCB is a smart pick.

How does The Summit PCB improve manufacturing efficiency?

The Summit PCB works well with automated machines. Its accurate design lowers mistakes during assembly. This saves time and materials, helping you make better products faster.

Is The Summit PCB suitable for small-scale manufacturers?

Yes, small and big manufacturers can use The Summit PCB. It fits modern production methods and scales easily. This makes it useful for businesses of all sizes.

Can The Summit PCB handle high-temperature environments?

Yes! The Summit PCB spreads heat evenly with special materials. It works well in hot places and stays reliable. This makes it perfect for tough conditions.

Note: Good heat control helps devices last longer.

What makes The Summit PCB future-proof?

The Summit PCB is ready for new technology. Its smart design and ability to scale keep it useful as electronics improve. It supports detailed layouts for advanced gadgets.

Emoji Insight: 🚀 Stay ahead with The Summit PCB for future needs!

See Also

Achieving High-Quality Outcomes Through PCBA Manufacturing Mastery

Locating the Ideal PCBA Manufacturer to Suit Your Requirements

Perfecting Innovative Techniques for PCBA Conformal Coating

Essential Technologies Shaping PCBA Production in Today’s Electronics