PCB assembly is a crucial component of industrial IoT gateway PCB assembly, significantly influencing their performance and reliability. Enhanced assembly techniques can improve power efficiency by up to 40%. Additionally, they can transmit signals 60% faster, ensuring smooth operation even in challenging environments. The global IoT gateway market was valued at $1,712.92 million in 2023 and is projected to expand to $5,439.78 million by 2032. Robust industrial IoT gateway PCB assembly is essential for this growth. Selecting the right IoT gateway PCB assembly ensures that your system remains future-ready, scalable, and compatible.

Key Takeaways

PCB assembly is important for IoT gateways. It boosts performance and makes systems more reliable. Good assembly can save up to 40% power.

Picking the right microcontroller matters a lot. It should process data quickly and handle many data streams at once.

Modular PCB designs make upgrades and changes simple. This saves money and time while letting your system grow as needed.

Security features like encryption and secure boot are a must. They keep your data and hardware safe from hackers and threats.

Power efficiency is very important for IoT gateways. Low-power parts and smart energy use cut costs and help the environment.

Understanding Industrial IoT Gateway PCB Assembly

Role of PCB Assembly in IoT Gateways

PCB assembly is key to how IoT gateways work. It connects parts like sensors, processors, and modules. This connection helps them communicate smoothly. Without good PCB assembly, gateways may slow down or not work well.

Industrial IoT gateway PCB assembly boosts efficiency. For example:

It can make up to 5,000 units every hour, showing speed.

IoT gateways help by predicting problems, saving time, and improving tasks.

Strong PCB assembly ensures IoT gateways work well in tough conditions.

Key Components in Industrial PCB Assembly

Industrial IoT gateway PCB assembly has important parts. These parts work together to make it strong and reliable. Key parts include:

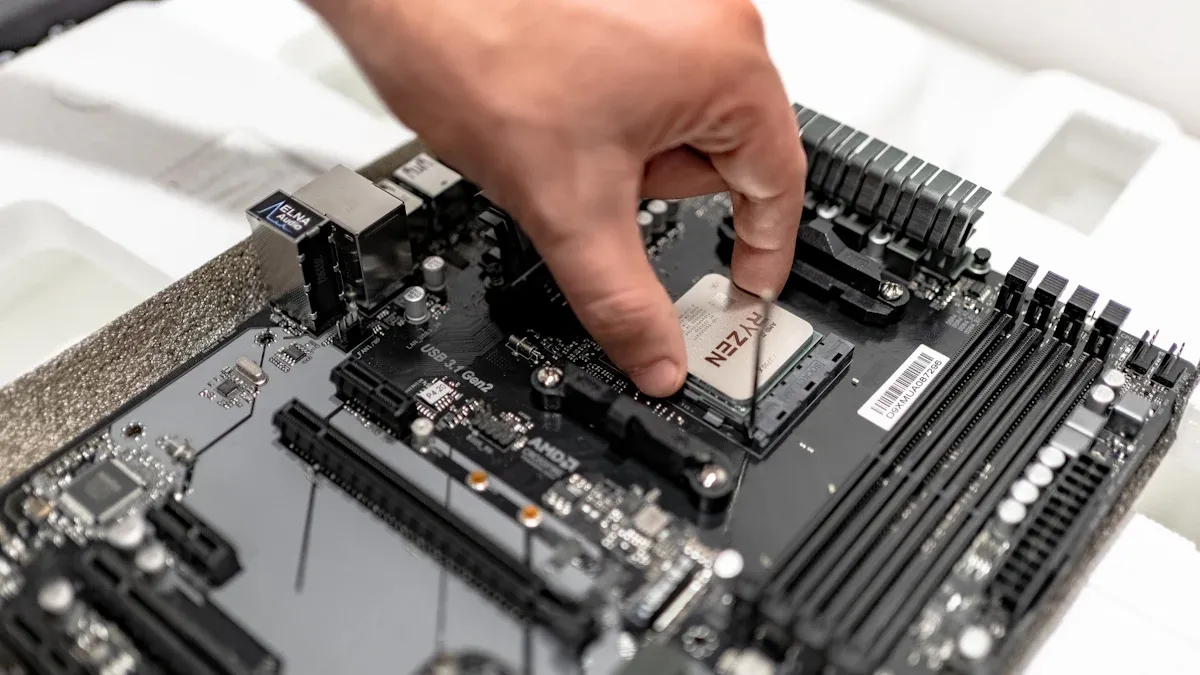

Microcontrollers and processors: They process data and make decisions.

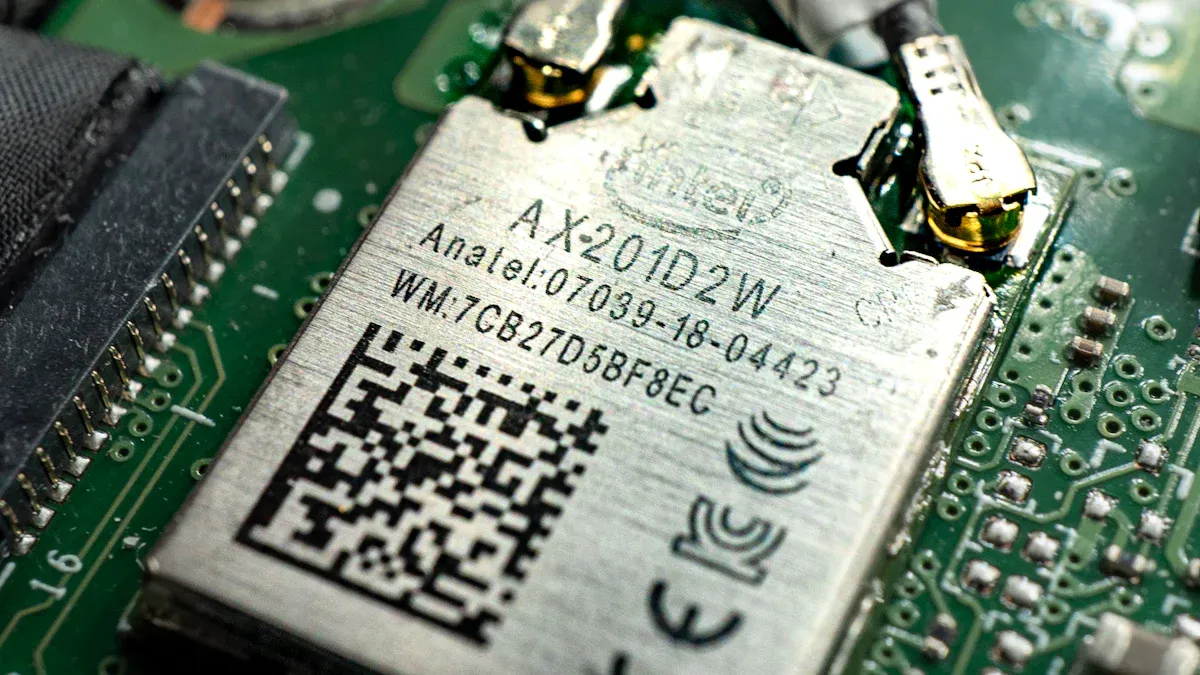

Connectivity modules: They allow communication using Wi-Fi, Bluetooth, or Ethernet.

Power management units: They save energy and keep things stable.

Sensors and interfaces: They gather and send data from the environment.

Each part must fit the needs of your IoT system.

Importance of Quality and Design in PCB Assembly

Good quality and design make PCB assembly last longer. Bad designs can cause signal issues, overheating, or failure. To fix this, makers use strong materials and smart designs. For example:

Special coatings protect against heat and moisture.

Parts are placed to avoid signal problems and keep signals clear.

Tools help manage heat, keeping performance steady.

Adding security tools and encryption keeps data safe. By focusing on quality, IoT gateways can handle tough industrial jobs.

Key Features of Industrial IoT Gateway PCB Assembly

Processing Power and Microcontroller Selection

The power of an IoT gateway depends on its microcontroller. Microcontrollers are like the gateway’s brain. They process data and make decisions. Picking the right one helps the gateway work fast and smoothly. With edge computing, microcontrollers now handle data closer to the source. This reduces delays and allows quick responses. This is very helpful in industries where fast decisions are important.

When choosing microcontrollers, check these features:

Can it support edge computing for faster responses?

Does it work with fog or mist computing systems?

Can it manage many data streams at once?

A microcontroller with these abilities makes your gateway reliable in tough situations.

Connectivity Options for IoT Gateways

Connectivity is how an IoT gateway talks to other devices. It affects range, speed, and energy use. Different technologies work better for different jobs and places.

Here’s a simple comparison of common connectivity types:

Technology | Range | Data Speed | Energy Use | Common Uses |

|---|---|---|---|---|

Wi-Fi | 50-100 meters | High | High | Smart homes |

Bluetooth LE | 10-30 meters | Low | Low | Fitness devices, trackers |

LoRaWAN | 2-15 km | Low | Low | Farms, city systems |

LTE-M | 10-15 km | Medium | Medium | Tracking items |

NB-IoT | 10-15 km | Low | Low | Utility meters |

For industrial gateways, long-range and low-energy options like LoRaWAN or NB-IoT are best. These are great for farming or remote monitoring where energy saving and reliability matter.

Durability and Environmental Resistance

Industrial IoT gateways often work in tough places. They deal with heat, cold, water, and dust. A strong PCB assembly keeps them working in these conditions. Special materials and coatings protect the parts from damage. For example, conformal coatings stop water and rust from harming the components.

Look for features that help with heat control. These stop the gateway from overheating, which can cause problems. A well-made PCB assembly with these protections keeps your gateway working, even in hard environments.

Scalability and Modularity

Scalability and modularity are important for industrial IoT gateway PCB assembly. They let you adjust your system as needs change without replacing everything. A modular design splits the PCB into smaller, separate parts. Each part can be fixed, upgraded, or swapped out on its own. This saves both time and money.

Here are some benefits of scalability and modularity:

Easier Customization: Pick parts that fit your exact needs.

Scalability: Increase or decrease production easily based on demand.

Improved Quality Control: Separate modules make checking for problems simpler.

Cost-Effective Inventory Management: Fewer module types mean lower storage costs.

Faster Market Response: Add new modules quickly to follow trends.

Sustainability: Repairs and recycling are easier, cutting down on waste.

The table below shows more advantages:

Advantage | Description |

|---|---|

Scalable design | Reuse IO cards across systems, keeping costs steady. |

Ease of Upgrades | Upgrade key parts like memory and storage easily. |

Simplified Repair | Fix single IO boards to save money and effort. |

Sustainability | Modular designs support repairs and upgrades, reducing waste. |

Choosing a modular and scalable PCB assembly keeps your IoT gateway flexible and ready for the future.

Power Efficiency and Energy Management

Power efficiency is very important for industrial IoT gateways, especially in remote areas. Good PCB assembly uses less energy while still working well. This lowers costs and helps the environment.

An Energy Resource Management (ERM) system can track and improve energy use. For example:

The ERM system checks energy use in real-time with power meters. It stores this data and studies energy use in tasks like drilling and soldering during PCB making. This cuts CO2 emissions and improves energy use.

When looking at power efficiency, think about these points:

Low-Power Components: Use parts like sensors that need less energy.

Dynamic Power Management: Change power levels based on tasks to save energy.

Battery Life Optimization: Make sure the gateway works well on batteries for a long time.

By focusing on energy use, you can make your IoT gateway work better and be eco-friendly.

Security Features in PCB Design

Security is very important for industrial IoT gateways. A good PCB design includes features to protect data and stop unauthorized access. These features keep your system safe from hackers and physical damage.

The table below lists key security features:

Security Feature | Description |

|---|---|

Secure boot mechanisms | Only trusted software runs when starting up. |

Hardware encryption accelerators | Protects data quickly with fast encryption. |

True random number generators (TRNG) | Creates strong keys for data protection. |

Secure element chips | Keeps sensitive data safe. |

Physical unclonable functions (PUF) | Gives unique IDs for secure access. |

Tamper-evident enclosures | Stops physical tampering. |

Active tamper detection circuits | Warns you if tampering happens. |

Conformal coatings | Protects parts from being copied. |

Buried vias for sensitive traces | Hides important connections from attacks. |

Secure storage for cryptographic keys | Keeps keys safe from being stolen. |

These features work together to make a strong security system. For example, secure boot mechanisms make sure only safe software runs. Encryption accelerators protect data without slowing things down. Coatings and tamper-proof cases add physical safety, making it harder for attackers to reach important parts.

By focusing on security in PCB design, you keep your IoT gateway safe and reliable in tough environments.

Comparative Analysis of IoT Gateway Products

Product A: PCB Assembly Features and Strengths

Product A is known for its strong processing and connectivity. Its PCB assembly has a powerful microcontroller for edge computing. This helps process data quickly, which is important for fast decisions. It also includes Wi-Fi, Ethernet, and Bluetooth for easy communication between devices.

Durability is another key feature of Product A. The PCB assembly has special coatings to block moisture and dust. This makes it great for tough industrial settings. Its modular design lets you swap or upgrade parts easily. This saves both time and money. Product A also focuses on saving energy. It uses smart power management to work well while using less energy.

Product B: PCB Assembly Features and Strengths

Product B is great for scaling and handling tough conditions. Its PCB assembly has a modular design for easy upgrades. You can add new parts without replacing the whole system. This makes it ready for future needs.

The PCB assembly is built to last. It has systems to stop overheating, so it works well in extreme heat or cold. Product B also includes tamper-proof cases and secure boot features. These protect both the hardware and data. It uses LoRaWAN and NB-IoT for long-range, low-energy tasks. This makes it perfect for farms or remote monitoring.

Product C: PCB Assembly Features and Strengths

Product C is small but powerful, making it very flexible. Its PCB assembly supports many communication types like RS232, CAN, and SPI. These allow it to connect with different devices and systems. It works with power supplies from 8V to 24V, giving more options.

The aluminum case makes Product C strong and keeps it cool without a fan. This means less upkeep and quieter use. It meets safety and environmental rules like FCC/CE and RoHS-II. It works in temperatures from -40° to 85° C, so it’s good for extreme places. A 5-year warranty adds extra trust in its reliability.

Feature | Specification |

|---|---|

Communication Interfaces | 1x RS232, 1x CAN, Up-to 1x UART, SPI, I2C, GPIO |

Supply Voltage | Unregulated 8V to 24V |

Dimensions | 108 x 83 x 24 mm |

Enclosure Material | Aluminum housing |

Cooling | Passive cooling, fanless design |

Compliance | FCC/CE, RoHS-II |

Operation Temperature | -40° to 85° C |

Warranty | 5 years |

Product C is energy-efficient and secure. It uses low-energy parts and smart power controls to save energy. Security tools like encryption and safe data storage protect sensitive information. These features make Product C a dependable choice for industrial IoT gateways.

Summary Table of Features and Differences

When picking an industrial IoT gateway, comparing features is helpful. Below is a table showing the main features and differences of Product A, Product B, and Product C.

Feature | Product A | Product B | Product C |

|---|---|---|---|

Processing Power | Strong microcontroller for edge computing | Medium power, built for scaling | Small but supports many communication types |

Connectivity | Wi-Fi, Ethernet, Bluetooth | LoRaWAN, NB-IoT | RS232, CAN, UART, SPI, I2C, GPIO |

Durability | Coatings resist dust and moisture | Heat protection, tamper-proof design | Aluminum case, no fan needed |

Scalability | Easy upgrades with modular design | Very scalable, ready for future needs | Compact and fits many uses |

Power Efficiency | Smart energy-saving system | Long-range, low-energy options | Uses low-energy parts, good for batteries |

Security Features | Secure boot, fast encryption | Tamper-proof and secure boot features | Encryption and safe data storage |

Operating Temperature | -20° to 70° C | -40° to 85° C | -40° to 85° C |

Warranty | 3 years | 3 years | 5 years |

Tip: Use this table to find the product that fits your needs. For example, Product B is great for long-range tasks. If you need a small design with many connection options, Product C is a good choice.

Key Takeaways

Product A: Best for tasks needing strong processing and quick communication. Its modular design and energy-saving tools make it great for edge computing.

Product B: Works well for big projects in remote areas. Its durability and long-range connections are perfect for farms or industrial jobs.

Product C: Small and flexible. It handles tough environments and has strong security, making it good for sensitive tasks.

By comparing these features, you can choose the best IoT gateway for your needs. Think about things like environment, scaling, and security before deciding.

Challenges in Picking an IoT Gateway

Balancing Cost and Performance

Choosing an IoT gateway can be tricky. You need one that fits your budget but also works well for your needs. High-performance gateways have features like faster processors and better durability. But these features often make them more expensive.

To find the right balance, think about what your project needs. For example:

Do you need fast data processing? If not, a mid-range gateway might work.

Will it be used in tough conditions? If yes, focus on durability instead of extra features.

Tip: Don’t pay for features you won’t use. Pick a gateway that matches your current and future needs.

Making Sure It Works with Your Systems

Compatibility is very important. The gateway must work with your devices, software, and networks. If it doesn’t, you might face delays or extra costs.

Before buying, check what the gateway supports. For example:

Does it work with your communication protocols like MQTT or Modbus?

Can it connect to your sensors and controllers?

Note: Test the gateway in a safe setting to spot problems early.

Choosing Between Scalability and Cost

Scalable gateways cost more at first. They let you add or upgrade parts as needed. This is helpful for growing projects but may not be worth it for smaller ones.

Think about your long-term plans. If you want to expand later, a scalable gateway can save money over time. But if your project is small or short-term, a simpler gateway might be better.

Key Insight: Scalability is like planning for the future. Decide if the extra cost fits your growth plans.

Importance of Vendor Support and Documentation

Picking the right industrial IoT gateway needs good vendor support and clear documentation. These help solve problems fast and make setup easier.

Why Vendor Support is Important

Good vendor support helps fix issues quickly. Industrial IoT systems often work in important areas where delays can cause big problems. A helpful vendor can offer:

24/7 Technical Assistance: Quick help anytime you need it.

Firmware Updates: Regular updates to keep things secure and running well.

Training Resources: Guides or lessons to teach your team how to use the gateway.

Tip: Choose vendors with a history of great customer service. Read reviews or ask others about their experience.

Why Documentation is Useful

Clear documentation is like a manual for using the gateway. It makes setup easier and helps avoid mistakes. Good documentation should include:

Step-by-Step Instructions: Easy-to-follow directions for setup.

Troubleshooting Guides: Fixes for common problems.

Technical Specifications: Details about features and compatibility.

Note: Good documentation saves time and reduces the need for extra help.

What to Check For

When looking at vendor support and documentation, think about these points:

Feature | Why It’s Important |

|---|---|

Response Time | Quick replies mean less waiting and downtime. |

Knowledge Base | FAQs, manuals, and videos make solving problems easier. |

Warranty and Repairs | Clear rules help if the hardware breaks. |

By choosing vendors with strong support and clear guides, your IoT gateway will work better and meet your project’s needs.

PCB assembly is important for how well industrial IoT gateways work. It helps with fast data handling, strong connections, and lasting performance in tough places. When choosing a gateway, look at features like power, growth options, energy use, and safety.

Tip: Pick features that fit your project. For example, choose modular designs for upgrades or tough builds for hard environments.

By matching the gateway to your goals, you can make your IoT system work better for a long time. Also, check for good vendor help and clear guides to make setup easier.

FAQ

1. What does PCB assembly do in industrial IoT gateways?

PCB assembly links parts like sensors and processors. It helps them work together and share data smoothly. A good PCB assembly makes devices stronger, faster, and more reliable in tough places.

2. How can I pick the best microcontroller for my IoT gateway?

Choose a microcontroller based on what your project needs. Think about speed, edge computing, and handling lots of data. A strong microcontroller helps your gateway work quickly and dependably.

3. Why is modularity useful in PCB assembly?

Modularity lets you change or upgrade parts without replacing everything. This saves money and time. It also helps your gateway grow and adjust to future needs.

4. What security features should a PCB design have?

Look for things like secure boot, encryption tools, and tamper-proof cases. These keep your data safe and protect your hardware from damage or hacking.

5. Why does power efficiency matter for industrial IoT gateways?

Power-efficient PCBs use less energy and cost less to run. They also make batteries last longer in faraway places. Features like low-energy parts and smart power controls save energy while keeping performance strong.

See Also

Evaluating Industrial Sensor PCB Assembly Services for 2025

Key Trends Influencing Industrial IoT PCB Assembly This Year

Leading Companies for Low Volume IIoT PCB Assembly 2025

The Impact of PCBA on Industrial Automation Efficiency

Exploring PCBA’s Importance in Industrial Automation Processes