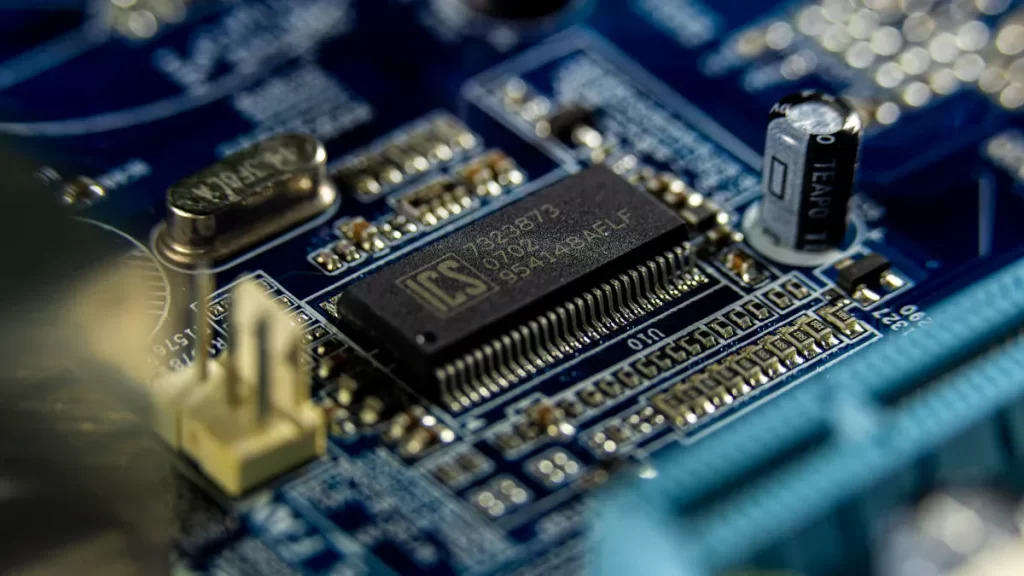

Custom PCBA solutions refer to the creation and assembly of circuit boards tailored for specific applications. These solutions play a crucial role in modern electronics, enabling unique designs, enhanced performance, and the support of emerging technologies.

The demand for custom PCBA solutions is rapidly increasing due to advancements in gadgets, IoT, and 5G. For instance:

The global gadget market is projected to reach USD 1,214.11 billion by 2024.

Investment in 5G technology could rise to USD 120 billion by 2024.

The IoT market is expected to grow from USD 250 billion in 2023 to USD 300 billion in 2024.

Partnering with a PCB store offering custom PCBA solutions provides you with expert assistance. This collaboration streamlines production, enhances quality, and addresses the demands of fast-evolving markets.

Key Takeaways

Custom PCBA solutions create circuit boards that fit specific needs.

These boards improve how products work and perform better.

Working with a good PCB store makes production faster and easier.

It also boosts quality and keeps up with new technology.

Saving money is possible by using fewer layers and simple designs.

These methods cut costs but still keep the boards high-quality.

Custom PCBA solutions help make products faster with quick prototypes.

They ensure smooth steps from design to production with testing included.

Picking a trusted PCB store gives access to new tech and expert help.

This leads to great products with high standards and good results.

Benefits of Custom PCBA Solutions

Meeting unique design and functionality needs

Custom PCBA solutions help make circuit boards fit your needs. They work for small gadgets like wearables or strong machines for factories. Technologies like SMT and through-hole assembly allow different part sizes, such as 1206 and 0603. Tests like ICT and FCT check if the boards work properly.

Feature | Description |

|---|---|

Component Sizes | Sizes like 1206, 0805, 0603 with SMT technology |

Testing Methods | ICT (In Circuit Test), FCT (Functional Circuit Test) |

Certifications | UL, CE, FCC, RoHS approved PCB assembly |

Soldering Technology | Nitrogen gas reflow soldering for SMT |

Assembly Types | SMT, Through-hole |

Solder Types | Water-soluble, Leaded, and Lead-Free solder paste |

Turn Time | Fast service from same day to 15 days |

Quality Control | AOI and X-ray inspection for real-time checks |

Production Capacity | From 1 board to 1000, prototype & low volume |

Customization | Adjustments based on customer needs |

These features make sure your boards work well and last long. Working with a PCB store offering custom PCBA solutions lets you turn your ideas into reality.

Ensuring high-quality and reliable performance

Electronics need to be reliable, especially for medical tools and imaging devices. Custom PCBA solutions use advanced methods to ensure great performance. Shielding layers cut electromagnetic interference by 60dB. Gold bonding makes devices last over 100,000 hours without breaking.

Challenge Type | Technical Solution | Performance Metrics |

|---|---|---|

Sterilization Resistance | Special materials for coating | Handles 200 autoclave cycles |

EMI Control | Multilayer shielding structures | Cuts radiation by 60dB |

Long-term Reliability | Gold bonding process | MTBF >100,000 hours |

Biocompatibility | Parylene coating | Meets ISO 10993-5 standards |

Medical devices can last over 10 years with leakage currents below 10μA. Imaging tools transfer data at 40 Gbps and resist interference up to 100V/m. These results show the precision and trust you get with custom PCBA solutions.

Achieving cost-efficiency in production

Custom PCBA solutions save money while keeping quality high. Cutting PCB layers from 14 to 10 lowers costs by 37%. Symmetrical designs stop warping during heating, keeping boards reliable. Switching from 12-layer FR4 to 8-layer hybrid designs saves 29% and keeps thermal performance strong.

Key Cost-Saving Strategies:

Cutting PCB layers from 14 to 10 saves 37% in costs.

Symmetrical designs stop warping during heating, ensuring reliability.

Changing from 12-layer FR4 to 8-layer hybrid designs saves 29% while keeping thermal performance.

These methods show how custom PCBA solutions reduce costs and improve production. Partnering with a PCB store offering custom PCBA solutions helps you save money while keeping quality high.

Accelerating product development timelines

Speed is very important in today’s markets. Custom PCBA solutions help you finish products faster. They make the process from design to assembly quicker. This saves time but still keeps quality high.

Here’s how custom PCBA solutions speed up product development:

Rapid Prototyping

Custom services let you make prototypes fast. Automated SMT assembly helps build prototypes quickly. You can test designs early and fix problems before full production starts.Smooth Design-to-Production Transition

Moving from design to production is made easy. Design-for-manufacturing (DFM) principles prepare designs for mass production. This removes delays and keeps work flowing smoothly.Built-in Testing and Validation

Testing happens during production to check PCB performance. ICT and FCT methods ensure boards work correctly. This reduces fixing errors later and meets all product needs.Flexible Lead Times

Custom PCBA solutions offer lead times from same-day to weeks. This helps meet tight deadlines and adjust to market changes.

Tip: Working with a PCB Store offering custom PCBA solutions gives you expert tools and knowledge. This partnership helps you launch products faster and stay ahead of competitors.

Using these methods lets you focus on new ideas while experts handle the details. Faster timelines mean quicker launches, more market chances, and happy customers.

The Process of Custom PCBA Solutions

Initial consultation and requirement analysis

Creating custom PCBA solutions starts with understanding your specific needs. In the first meeting, you explain your project goals and design ideas. This step ensures the final product matches your vision.

Engineers review your details to choose the best materials and methods. They also check for challenges like size limits or environmental issues that might affect the circuit board’s performance.

Tip: Share clear expectations and detailed documents. This helps the team create a solution that fits your needs perfectly.

At the end of this step, you get a detailed plan. It includes the design process, costs, and timelines. This plan helps keep the project smooth and organized.

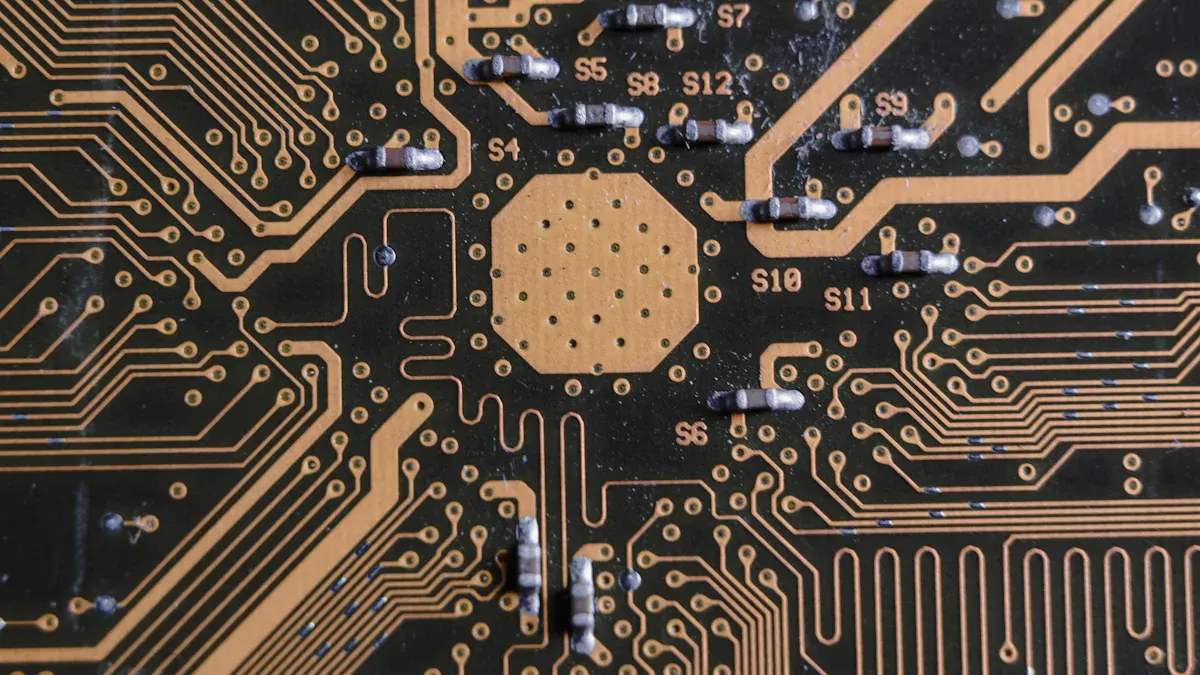

Prototyping and design refinement

After setting requirements, the next step is making a prototype. A prototype lets you see and test your design. Engineers use tools like CAD software and automated SMT assembly to build it quickly and accurately.

Testing is very important during this phase. Engineers run tests like ICT and FCT to check if the prototype works well. If problems are found, they fix the design to improve it.

Prototyping Benefits | Description |

|---|---|

Early Issue Detection | Finds design problems before production |

Cost Efficiency | Saves money by avoiding mistakes |

Faster Iterations | Speeds up design improvements |

This process ensures the final design is reliable and efficient. You can move forward knowing your product has been tested and improved.

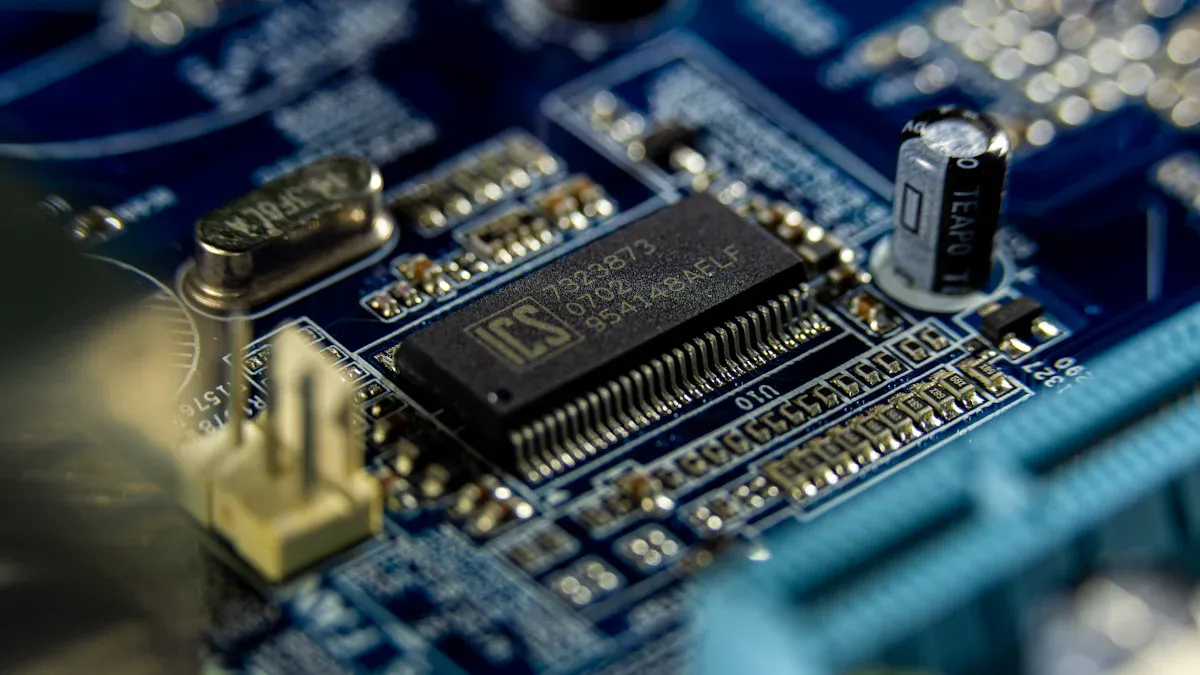

Production and assembly

Once the design is ready, production and assembly begin. This step turns your prototype into a working product. Manufacturers use advanced machines to assemble parts with precision.

SMT is used for small designs, while through-hole assembly is for stronger builds. Automated tools like pick-and-place machines and reflow soldering ensure every unit is made correctly.

Quality checks are done throughout production. Inspections like AOI and X-ray analysis make sure each board meets high standards. These checks prevent defects and ensure the boards work well.

Note: Working with a PCB Store offering custom PCBA solutions gives you access to top technology and expert advice during production.

At the end of this step, you get a high-quality product ready to use. The smooth shift from design to production keeps your project on time and within budget.

Quality checks and final delivery

Quality checks make sure your custom PCBA solutions are top-notch. This step includes careful testing, inspections, and validations. It ensures your product works well and avoids costly mistakes.

Detailed Testing Steps

Testing is very important for quality checks. Engineers use smart tools to test how well your PCBA works. AOI looks for problems like bad soldering or missing parts. X-ray scans check inside layers for hidden issues. These tests make sure every board matches your needs.

Tip: Testing during production finds problems early and saves money.

Tough Condition and Stress Tests

Your PCBA must work in tough conditions. Tests mimic extreme heat, cold, and shaking to check strength. Stress tests see how the board handles heavy use and pressure. These tests prove your product can handle real-world challenges.

Final Checks and Certifications

Before shipping, your PCBA gets a final check. Engineers make sure all parts work and meet rules. Certifications like UL, CE, and RoHS show your product is safe and eco-friendly. These approvals build trust in your product.

Safe Packing and On-Time Delivery

The last step is packing your PCBA safely. Anti-static wraps and custom boxes protect it during shipping. Delivery is planned to get your product to you on time.

Working with a PCB Store offering custom PCBA solutions gives you these quality checks. This teamwork ensures your product is safe, reliable, and ready for success.

Choosing the Right PCB Store Offering Custom PCBA Solutions

Checking technical skills and experience

Picking the right PCB store needs checking their skills. A store with years of experience, like PCBasic, shows they can deliver good results. Over 10 years in PCB and PCBA work proves they are reliable.

Good technical skills also mean using advanced tools and helping customers. Stores with modern machines make PCB assembly faster and more accurate. Support teams help with special project needs, making the process smooth.

Aspect | Description |

|---|---|

Technical Expertise | PCBasic has over 10 years of experience in PCB & PCBA manufacturing, ensuring high-quality outcomes. |

Quality Control | Comprehensive inspection processes and advanced equipment guarantee meticulous attention to detail. |

Advanced Technology | Utilization of state-of-the-art machines for precise PCB assembly enhances production efficiency. |

Customer-Centric Service | Dedicated support to meet unique project requirements ensures a knowledgeable partnership. |

By looking at these points, you can find a PCB store that fits your needs and delivers great results.

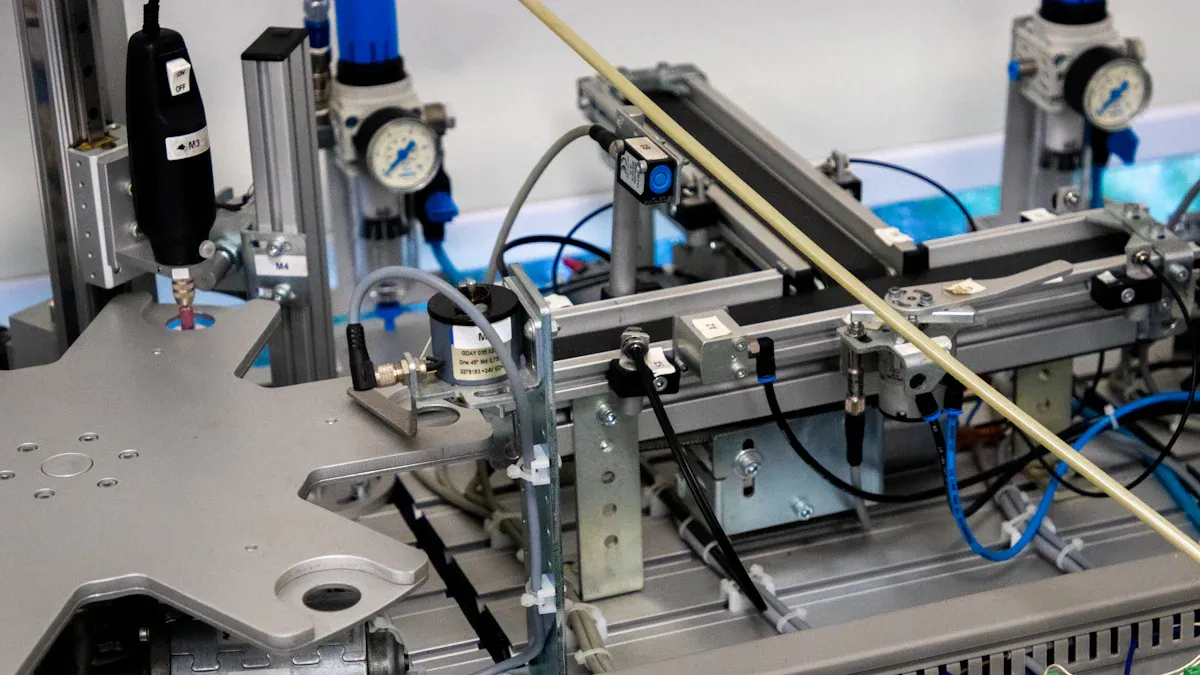

Looking at manufacturing abilities and tools

A PCB store’s abilities show how well they can handle your project. Look for stores with tools like automated SMT assembly and pick-and-place machines. These tools make production fast and accurate.

A good store can handle both small and big orders. This flexibility helps you meet market needs without losing quality. Advanced tools like multilayer PCB assembly also ensure your product works well with modern standards.

When checking manufacturing abilities, see if the store can handle different project sizes and deadlines. This keeps your product development smooth and on time.

Checking quality control rules

Quality control shows how much a PCB store cares about reliable products. Choose stores that follow important certifications. Standards like ANSI/ESD S1.1-2021 protect against static electricity and keep products safe during production.

Standard/Certification | Description |

|---|---|

ANSI/ESD S1.1-2021 | ESD control standard for the protection of electronic devices. |

ANSI/ESD STM2.1–2018 | Standard for ESD control program evaluation. |

ANSI/ESD STM3.1-2015 | Standard for ESD control in manufacturing environments. |

ANSI/ESD STM4.1–2017 | Standard for ESD control in handling and packaging. |

ANSI/ESD STM7.1-2020 | Standard for ESD control in testing environments. |

ANSI/ESD STM9.1-2022 | Standard for ESD control in product qualification. |

ANSI/ESD STM11.11-2022 | Standard for ESD control in assembly processes. |

ANSI/ESD STM11.12-2021 | Standard for ESD control in design processes. |

ANSI/ESD STM11.13-2021 | Standard for ESD control in maintenance processes. |

ANSI/ESD STM11.31-2018 | Standard for ESD control in system-level testing. |

These certifications make sure your PCBA solutions meet strict quality rules. A store with strong quality checks reduces mistakes and ensures reliable products. Checking these rules helps you pick a partner that values quality.

Thinking about customer support and service dependability

Good customer support and reliable service are very important when picking a PCB store. You need a partner who listens, answers questions, and keeps you updated. A dependable store communicates well and fixes problems fast, keeping your project on schedule.

Here are important things to check:

Quick Responses

A great PCB store replies to your questions quickly. Whether you need help with designs or updates, fast answers save time and reduce worries.Expert Help

Choose a store with skilled staff. They should guide you in picking materials, assembly methods, and testing steps. This makes sure your product meets all standards.Support After Delivery

After-sales help is very important. If problems happen after delivery, the store should help fix them. This builds trust and keeps you happy with their service.

Tip: Before ordering, ask the store some questions. Their reply speed and helpfulness show how much they care about customers.

A PCB store offering custom PCBA solutions should focus on your needs at every step. Good support makes the process easy, and reliable service ensures your project succeeds. Picking a store with these qualities gives you confidence and helps you reach your goals smoothly.

Advantages of Working with a Trustworthy PCB Store

Using advanced PCBA technologies

Modern PCBA technologies make products better and faster to create. Tools like AI and automation improve designs and save time. Industries like cars and medical devices need these tools for reliable results. AI tools find design mistakes early, ensuring great quality.

Cloud-based systems are also important. They let teams work together in real-time. This speeds up decisions and uses data to predict problems. These tools help meet market needs quickly. Partnering with a PCB store gives you access to these technologies, making your products stand out.

Faster and smoother production processes

Good production processes cut waste and boost efficiency. Reliable PCB stores use smart tools and clear workflows to improve operations. Companies like Raymundos and Royal Unibrew show how this works.

Company | How They Improved Production | OEE Change |

|---|---|---|

Danish Crown | Used Factbird to make operations better | N/A |

SIP Manufacturing | Reduced waste and improved team engagement | N/A |

Raymundos | Raised OEE by 20 points and improved data collection | +20 points |

Royal Unibrew | Made production lines better and raised OEE by 14% | +14% |

McBride | Got full transparency over production lines | N/A |

These examples show how better processes improve productivity. A trustworthy PCB store keeps production smooth, helping you save money and meet deadlines.

Growing your business and saving money

Growing businesses need flexible solutions. A good PCB store adjusts to your needs, whether for small or big orders. They help you scale production without losing quality.

Cost savings come from smart designs and less wasted materials. For example, hybrid PCB designs cost less but still work well. These methods keep your products affordable and competitive. Working with a reliable PCB store helps your business grow while staying within budget.

Custom PCBA solutions provide great benefits like custom designs, strong performance, saving money, and quicker product creation. These features help you make new products that fit market needs.

Picking a reliable PCB store gives you modern tools, expert advice, and steady quality. This teamwork makes production easier and helps your product succeed.

Start now. Look into custom PCBA solutions to bring your ideas to life and stay ahead in the fast-moving electronics world.

FAQ

What is a custom PCBA solution?

A custom PCBA solution means making circuit boards just for you. It helps your product meet special design, performance, and function needs.

How do custom PCBA solutions save costs?

Custom PCBA solutions save money by improving designs and reducing waste. Using hybrid PCB designs can cut costs while keeping good quality.

How long does it take to complete a custom PCBA project?

The time depends on how complex your project is. Custom PCBA solutions can be done quickly, from the same day to a few weeks.

What industries benefit from custom PCBA solutions?

Industries like healthcare, cars, IoT, and telecom use custom PCBA solutions. These solutions help with new technology and reliable performance.

How do I choose the right PCB store for custom PCBA solutions?

Pick a store with good experience, modern tools, strong quality checks, and helpful support. These things make your project successful.

See Also

How To Choose The Ideal PCBA Manufacturer For You

Comparing Turnkey And Consignment PCBA Manufacturing In 2025

Evaluating Leading PCBA Providers In The Industry 4.0 Era

Achieving High-Quality Results Through PCBA Manufacturing Mastery