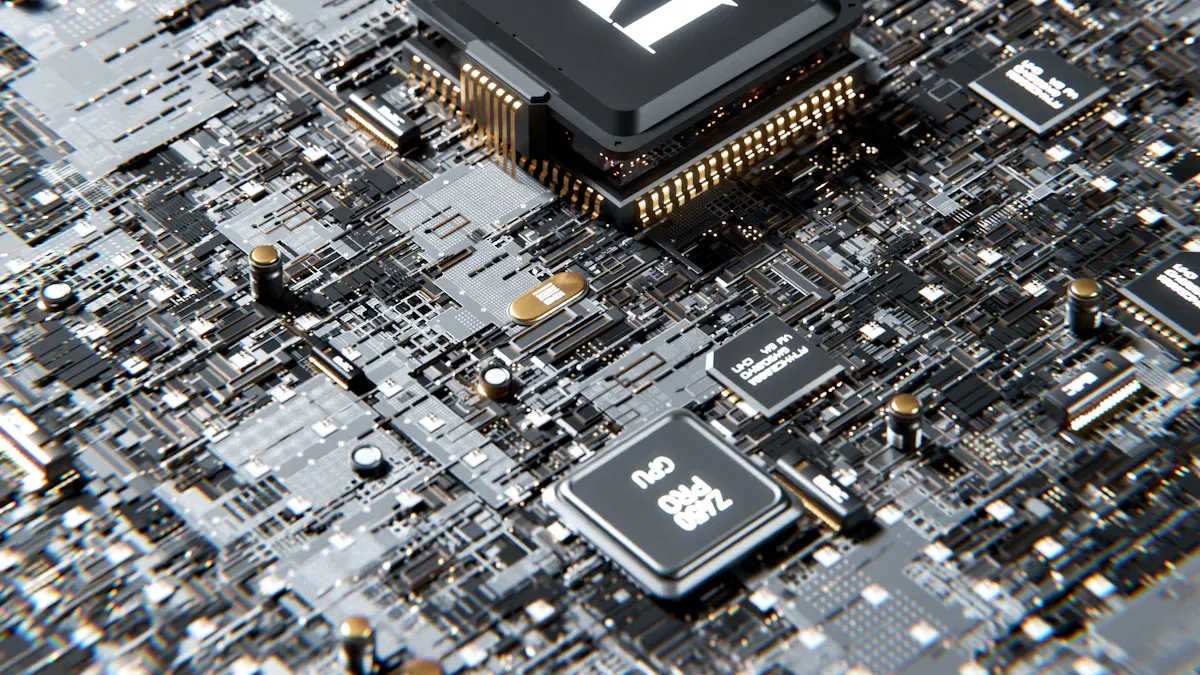

AI-driven PCB design is revolutionizing how circuit boards are created, offering a smarter approach to the process. With tools like coyote ugly PCB AI-Driven PCB Design, artificial intelligence automates complex tasks, optimizes layouts, and sparks innovative ideas. These intelligent systems take care of repetitive jobs, allowing you to concentrate on design and functionality. This approach not only saves time but also minimizes errors and ensures designs meet industry standards. Whether you’re prototyping or producing large quantities, AI-driven solutions like coyote ugly PCB help you work more efficiently and effectively.

Coyote ugly PCB AI-Driven PCB Design empowers you to explore groundbreaking methods for building PCBs and stay ahead in the rapidly evolving tech landscape.

Key Takeaways

AI helps with PCB design by handling boring tasks. This lets you focus on new ideas and being creative.

AI makes designs better by spotting problems early. This avoids expensive errors in your work.

AI tools use resources wisely, saving money and making greener PCBs.

Using AI improves teamwork, helping your group create better designs together.

Learn about AI trends to find new ways to improve your PCB skills.

What is AI-Driven PCB Design?

Definition and Core Principles

AI-driven PCB design uses artificial intelligence to improve how circuit boards are made. It uses smart programs and machine learning to do tasks, fix layouts, and find problems early. This helps you make circuit boards faster and more accurately. AI tools study lots of data to spot patterns and give helpful ideas, making the design process easier and better.

The main ideas of AI-driven PCB design are automation, optimization, and creativity. Automation handles boring tasks like placing parts and connecting them. Optimization checks if the design works well and costs less by looking at many factors at once. Creativity comes from AI finding new ways to solve problems, letting you try fresh ideas for designs.

Using AI in PCB design gives you tools that simplify hard jobs and make your designs better. This makes AI-driven PCB design a key method for creating modern electronics.

How It Differs from Traditional PCB Design Methods

Traditional PCB design depends on engineers doing most of the work by hand. You spend hours placing parts, connecting them, and checking the design. While this gives control, it takes longer and can lead to mistakes.

AI-driven PCB design automates many of these steps. AI programs quickly create good layouts, find mistakes, and suggest fixes. This saves time and effort while making designs more accurate. For example, AI can spot signal problems before they happen, avoiding expensive fixes later.

Another big difference is how well it handles complex designs. Traditional methods struggle with modern electronics’ growing challenges. AI tools work well with big data and tricky designs. They adjust to your needs, making them great for simple or advanced circuit boards.

Switching to AI-driven PCB design helps you avoid the limits of older methods. It speeds up your work and lets you try new ideas in electronics design.

How AI is Used in PCB Design

Machine Learning in Design Optimization

Machine learning helps improve PCB design by finding useful patterns. It studies large amounts of data to suggest better layouts. For example, it can recommend where to place parts or connect wires. This process, called design optimization, makes your PCB work well and saves materials. AI lets you test many design ideas quickly, saving time compared to doing it by hand.

Machine learning also predicts how your PCB will perform in different situations. It checks heat levels, signal quality, and power flow. These insights help you improve your design without guessing. This method reduces mistakes and saves both time and money.

Automation of Repetitive Tasks

Automation makes boring PCB design tasks faster and easier. Jobs like placing parts, connecting them, and checking rules take a lot of time. AI tools can do these tasks quickly and correctly. For example, AI can arrange parts to save space and improve function. It can also connect wires while following design rules to meet standards.

By automating these tasks, you can focus on creative parts of your project. This speeds up your work and lowers the chance of mistakes. Automation also helps with tricky designs, making it a must-have for modern PCB work.

Predictive Analysis for Error Detection and Correction

Predictive analysis uses AI to spot problems in your PCB design early. It looks for issues like bad signals, overheating, or wrong connections. Finding these problems early prevents expensive fixes later.

AI tools also suggest ways to fix errors fast. For instance, if there’s a signal problem, the tool might suggest changing wire paths. This smart approach ensures your PCB works well and avoids failures.

Benefits of AI-Driven PCB Design

Enhanced Efficiency and Faster Design Cycles

AI-driven PCB design speeds up your work by automating tasks. Instead of placing parts or connecting wires yourself, AI does it. This lets you focus on creative design ideas. For example, AI checks many layouts and picks the best one. This saves time and avoids guesswork.

AI also shortens the time needed to finish designs. Traditional methods often need many fixes to solve problems. With AI, you find and fix issues early. This smoother process helps you launch products faster.

Improved Reliability and Reduced Errors

AI makes your PCB designs more reliable by cutting down mistakes. Manual work can lead to errors like wrong placements or bad connections. AI tools spot these problems before they cause trouble. For example, they can find signal issues or overheating risks and offer fixes.

Fewer mistakes mean your PCB works as it should. This is crucial for complex designs where small errors can cause big failures. With AI, you can create dependable circuit boards that meet high standards.

Cost Savings Through Optimized Resource Usage

AI helps you save money by using materials wisely. It checks your design to use parts and space efficiently. For instance, it might suggest shrinking your PCB without losing function. This lowers costs and makes your designs eco-friendly.

AI also cuts costs by avoiding expensive fixes. It finds and solves problems early, so you don’t waste money on redoing designs. Plus, faster design times free up resources for other projects, boosting productivity.

Tip: Using AI for PCB design saves time, money, and keeps you ahead in a fast-changing industry.

Enabling Innovation with Advanced Design Capabilities

AI-driven PCB design helps create new ideas and solutions. It offers tools that go beyond old methods, letting you try fresh approaches and build advanced electronics.

1. Generating Unique Design Concepts

AI helps you think creatively by studying lots of data. It suggests new layouts or setups you might not imagine. These ideas often lead to better designs that work smarter and more efficiently.

Note: AI doesn’t just improve old designs; it inspires brand-new ideas.

2. Supporting Complex Designs

Modern electronics need detailed PCBs with many parts and layers. AI makes this easier by placing parts and connecting them automatically. It ensures even tough designs meet high standards and stay reliable.

3. Simulating Real-World Scenarios

AI tools let you test your designs in virtual settings. These tests show how your PCB will handle heat, electricity, and other conditions. Fixing problems early helps you improve the design before making it.

4. Encouraging Collaboration

AI tools help teams work together on PCB projects. They share useful insights, making it easier to brainstorm and improve designs as a group. This teamwork leads to better ideas and stronger solutions.

5. Unlocking Customization Opportunities

AI lets you adjust PCB designs for specific uses. Whether for gadgets, cars, or medical tools, AI adapts to your needs. This ensures your designs are both creative and perfect for their purpose.

Tip: Use AI to customize designs that match your project’s goals and needs.

Real-World Uses of AI in PCB Design

Industries Using AI for PCB Creation

AI is changing how industries make PCBs. It helps in areas needing accuracy, speed, and new ideas. For example, the electronics industry uses AI to design small, powerful PCBs for phones, watches, and smart devices. AI makes sure these products work well and last long.

In cars, AI designs PCBs for systems like navigation and safety. Electric vehicles also need special PCBs for energy control. AI tools make these designs faster and with fewer mistakes.

The medical field uses AI for devices like pacemakers and scanners. These tools need very reliable PCBs. AI predicts problems and improves layouts for better results. Aerospace and telecom industries also use AI for tough tasks, like handling extreme conditions or fast data speeds.

Examples of AI-Powered PCB Tools

Some tools show how AI helps in PCB design. One is Autodesk’s Fusion 360. It uses AI to automate tasks like placing parts. It also gives tips to improve designs, saving time for creative work.

Another tool is Cadence’s Allegro X AI. It uses machine learning to find problems in your design. It gives instant feedback so you can fix issues early. Engineers in telecom and car industries use it to make better PCBs.

Zuken’s CR-8000 is another great tool. It mixes AI with 3D design, letting you test your PCB virtually. This ensures the design works before production starts. These tools show how AI makes hard jobs easier and improves PCB quality.

Challenges and Future Outlook for AI in PCB Design

Current Limitations and Challenges

AI in PCB design has improved a lot but still has issues. One big problem is needing good-quality data. AI systems learn from large datasets to work better. If the data is wrong or missing, the results can be disappointing. This might cause mistakes in design suggestions.

Another challenge is fitting AI tools into current workflows. Learning new software or training your team can be hard. Also, AI sometimes struggles with very unique PCB designs. In these cases, human skills are still important.

Cost is also something to think about. Advanced AI tools can be expensive. Smaller companies might find it hard to afford them.

Note: AI helps automate tasks, but humans must check designs to ensure they meet all needs.

Trends and Opportunities in the Future of AI-Driven PCB Design

The future of AI in PCB design is exciting. One trend is creating easier-to-use AI tools. These tools aim to make designing simpler for everyone, even beginners.

Another opportunity is using cloud-based platforms. These let teams work together online, no matter where they are. They also give access to strong AI tools without needing costly equipment.

AI is expected to handle tricky designs better soon. Smarter algorithms will understand complex needs, helping you make custom PCBs.

AI can also help with eco-friendly designs. It can save materials and energy, making greener PCBs possible.

Tip: Keep up with these trends to use AI fully and stay ahead in PCB design.

AI-driven PCB design changes the way circuit boards are made. It saves time by handling repetitive tasks automatically. It reduces mistakes, making designs more dependable. Advanced tools also help you come up with creative ideas. Using AI keeps you ahead in a fast-changing world where accuracy and speed are crucial.

Key Takeaway: Using AI in PCB design helps you create better, faster, and more reliable electronics.

The future of AI in PCB design is very promising. As these tools improve, they will open up new opportunities. This will allow you to explore exciting ideas and advance technology further.

FAQ

1. How does AI improve PCB design accuracy?

AI finds problems like overheating or signal issues early. It gives fixes before production starts, avoiding costly mistakes. This helps your PCB meet high standards for performance and reliability.

2. Can AI handle complex PCB designs?

Yes, AI is great for tricky designs. It places parts and connects them automatically while following rules. This makes it perfect for multi-layered or high-density PCBs.

3. Is AI-driven PCB design suitable for small businesses?

AI tools save time and reduce mistakes, helping small teams. Some tools may cost more, but many offer affordable plans or cloud options. This makes them easier for small businesses to use.

Tip: Try AI tools with free trials or flexible pricing to see their benefits.

4. Do I need technical expertise to use AI tools for PCB design?

Most AI tools are simple and work for all skill levels. They include guides and easy-to-use features to help you start fast. Still, knowing basic PCB design ideas is useful.

5. What industries benefit the most from AI-driven PCB design?

Industries like electronics, cars, space, and healthcare use AI the most. These fields need accurate and reliable designs, which AI tools provide well.

Note: AI works for many industries, solving modern PCB design challenges easily.

See Also

Exploring AI’s Advantages in PCB Assembly Operations

Discover AI’s Role in Advancing PCBA for Electronics

Leading Trends in Smart Manufacturing for PCBA 2025

Essential Technologies Shaping PCBA Production for Electronics