Industrial work is changing fast with new digital tools. IIoT hardware manufacturing plays a crucial role in connecting machines, sensors, and systems. This integration allows for easy data sharing and quick decision-making. Many companies are already leveraging these tools—89% are building digital factories and IIoT projects. Smart factories could add $1.5 trillion to the world economy by 2030.

Choosing the right IIoT hardware manufacturing is very important. It enhances data processing, saves energy, and improves work efficiency. For example, IIoT tools can predict problems before they occur, reducing downtime and extending the lifespan of machines. They also utilize edge computing to process data nearby for faster results. With digital twins and 5G becoming commonplace, robust IIoT hardware manufacturing is now more essential than ever.

Key Takeaways

IIoT hardware links machines to share data and make decisions.

Picking good IIoT hardware saves time, cuts delays, and makes better products.

Check if the hardware works well, can grow, and is safe for your business.

Popular IIoT tools like Siemens SIMATIC IoT2040 and Rockwell FactoryTalk Edge Gateway help with automation.

Buying IIoT hardware can save money over time by reducing waste and working better.

What Is IIoT Hardware and Why Does It Matter?

Definition and Components of IIoT Hardware

IIoT hardware includes physical tools that power the Industrial Internet of Things (IIoT). These tools link machines, sensors, and networks to gather and process data. Important parts are wearable devices, mobile apps, and data tools. Wearables use sensors and computing to collect accurate data. Mobile apps help workers get information while moving around. Other features include dashboards for tracking, remote data access, and links to other services.

Component/Specification | Description |

|---|---|

Wearable Computing | Uses sensors and computing to gather accurate data invisibly. |

Mobile Apps | Helps workers get detailed information while on the move. |

Data Collection and Analysis | Improves knowledge and predictions for better operations. |

Remote Access to Data and Analytics | Allows faster fixes and smarter planning with expert help. |

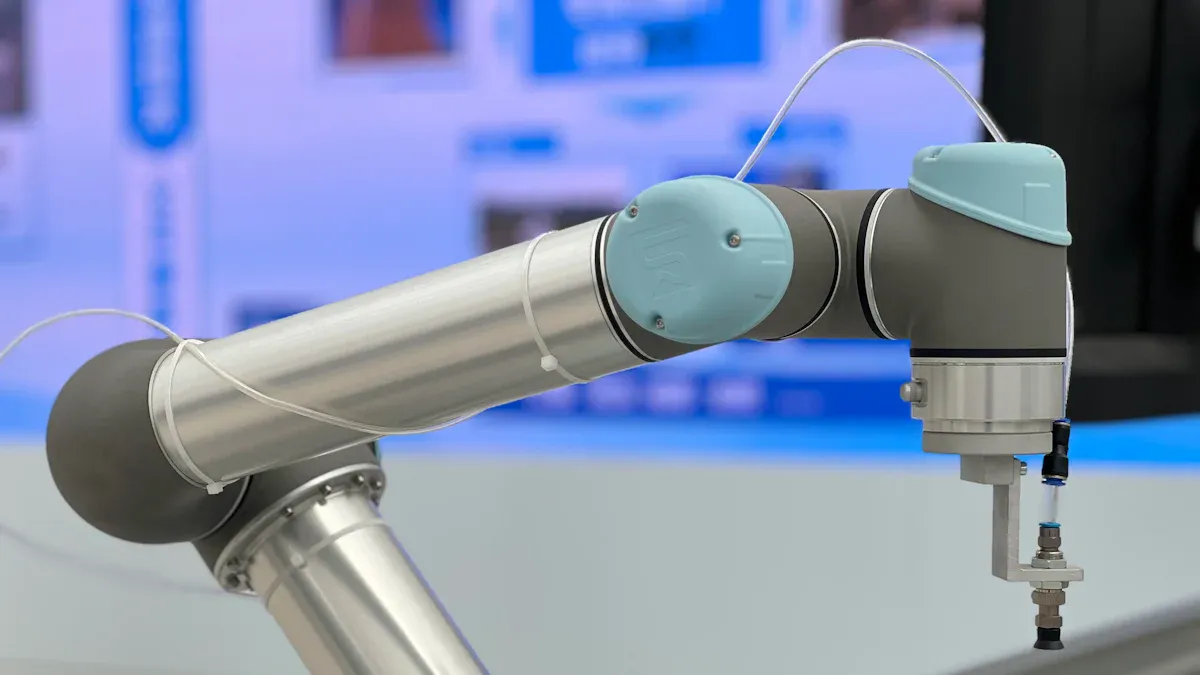

Role of IIoT Hardware in Industrial Applications

IIoT hardware is key in today’s industrial work. It connects IT and operational systems for smooth communication. This hardware boosts automation, saves time, and helps monitor in real-time. Smart devices can predict when machines might fail, cutting downtime and repair costs. It also uses advanced tech like AI to study data and take action faster.

Tip: Use IIoT hardware to make work safer, improve quality, and run operations better.

Benefits of IIoT Hardware for Manufacturing and Beyond

IIoT hardware helps more than just factories. It tracks equipment to improve how it works. Predictive maintenance stops problems before they grow. Real-time data helps make smarter decisions and boosts efficiency. For example, digital twins in IIoT platforms can manage data and improve product quality. IIoT hardware also makes workplaces safer by checking conditions and equipment use.

Key Benefits of IIoT Hardware:

Better product quality with improved monitoring.

Lower costs by avoiding setup mistakes.

Safer workplaces and smoother operations.

Top IIoT Hardware Solutions for Industrial Use in 2025

Solution 1: Siemens SIMATIC IoT2040

The Siemens SIMATIC IoT2040 is a strong and dependable device for factories. It connects old systems with new IoT tools, making data sharing easy. This hardware works well for edge computing, where fast data processing matters. Its small size and low energy use make it great for many industrial tasks.

Key features include options like Ethernet and wireless connections. These help it fit smoothly into current setups. It works with open-source software, so you can adjust it for your needs. It also links to cloud platforms, making data tracking and remote checks simple.

Note: The SIMATIC IoT2040 helps predict problems and automate tasks. This reduces downtime and makes work more efficient.

Solution 2: Advantech WISE-EdgeLink

Advantech WISE-EdgeLink is a flexible IIoT tool that connects equipment to the cloud. It gathers, processes, and sends data from machines to cloud systems. It supports many industrial protocols, so it works with different setups.

A key feature is its built-in security system, which keeps your data safe. It also connects easily to IoT platforms, making setup and management simple. Its easy-to-use design lets you quickly set up and monitor devices.

WISE-EdgeLink is great for industries like energy, transport, and manufacturing. It improves operations with real-time data and automation. Its ability to grow with your business ensures long-term benefits.

Solution 3: Cisco Industrial IoT Gateways

Cisco Industrial IoT Gateways link factory devices to the Internet of Things. They are tough and reliable, built for hard conditions. They offer both wired and wireless connections, giving flexibility for different uses.

These gateways have strong security tools like encryption and threat detection to protect data. They also process data quickly with edge computing, making them ideal for tasks needing fast results.

Tip: Cisco Industrial IoT Gateways are great for industries like cars, healthcare, and utilities. They ensure safe and smooth data sharing.

The IoT hardware market is growing fast. Reports say it will reach USD 475.18 billion by 2025, with a yearly growth rate of 23.5% until 2034. This shows how more industries are using IIoT hardware.

Report Attributes | Details |

|---|---|

Market Size Value in 2025 | USD 475.18 billion |

Revenue Forecast by 2034 | USD 3,179.26 billion |

CAGR | 23.5% from 2025 to 2034 |

These tools show how IIoT hardware is changing industries. They help connect systems, automate tasks, and make smarter decisions. Whether you want better productivity, safer systems, or smoother work, these devices can help.

Solution 4: PTC ThingWorx Edge

PTC ThingWorx Edge is a strong tool for easier industrial work. It connects machines to the Internet of Things (IoT) for smooth data sharing. This makes it great for industries wanting better automation and smarter decisions using data.

A key feature is its ability to work with many IoT platforms. This allows full connectivity, so you can check and control equipment from anywhere. It’s quick to set up, so you can start using it fast. Strong security features keep your data safe from threats, ensuring reliable use.

PTC ThingWorx Edge is perfect for tasks needing real-time data. It can study machine performance and predict problems before they happen. This lowers downtime and boosts efficiency. Its ability to grow makes it useful for both small and big industries.

Tip: Use PTC ThingWorx Edge to understand your work better and make smarter choices with data.

Solution 5: Rockwell Automation FactoryTalk Edge Gateway

Rockwell Automation FactoryTalk Edge Gateway is another great IIoT hardware for 2025. It helps collect and connect data across all your systems. This creates one network for smooth data flow.

Its standout feature is turning raw data into useful insights. It uses advanced tools to find patterns, improve processes, and boost productivity. This hardware works well in many industries, like manufacturing and energy.

The easy-to-use design makes setup and management simple. You can start collecting data quickly without needing special skills. Its strong security keeps your data safe at all times.

This tool is ideal for industries wanting better automation and smoother work. By using it, you can save money and work more efficiently.

Note: Rockwell Automation FactoryTalk Edge Gateway is a smart pick for industries upgrading their systems to stay ahead in a fast-changing world.

Comparison of IIoT Hardware Solutions

Key Features and Specifications of Leading Solutions

Each IIoT hardware has special features for industrial tasks. Siemens SIMATIC IoT2040 is small, saves energy, and supports edge computing. Advantech WISE-EdgeLink has strong security and connects easily to the cloud. Cisco Industrial IoT Gateways offer secure connections and detect threats. PTC ThingWorx Edge shares data smoothly and works with many IoT platforms. Rockwell Automation FactoryTalk Edge Gateway turns raw data into useful insights, boosting work efficiency.

Solution | Key Features |

|---|---|

Siemens SIMATIC IoT2040 | Small, energy-saving, supports edge computing. |

Advantech WISE-EdgeLink | Strong security, cloud-ready, works with many protocols. |

Cisco Industrial IoT Gateways | Wired/wireless connections, encryption, threat detection. |

PTC ThingWorx Edge | Real-time data sharing, IoT platform support, secure. |

Rockwell FactoryTalk Edge Gateway | Turns data into insights, finds patterns, easy to set up. |

Strengths and Weaknesses of Each Hardware

Knowing the pros and cons of these tools helps you choose wisely. Siemens SIMATIC IoT2040 is efficient but may need extra software for advanced tasks. Advantech WISE-EdgeLink has great security but might need adjustments for specific uses. Cisco Industrial IoT Gateways are tough and secure but can be pricey for small businesses. PTC ThingWorx Edge is scalable and offers real-time insights but may take time to learn. Rockwell FactoryTalk Edge Gateway simplifies data use but may struggle with very complex systems.

Tip: Match your needs with the strengths and weaknesses of each tool.

Ideal Use Cases for Different Industrial Scenarios

Different industries use specific IIoT hardware for better results. SIG used PTC ThingWorx Edge to save energy and lower carbon emissions. Flowserve improved reliability with IoT-based monitoring. The Griffin’s Food Company sped up operations using IIoT tools. Vattenfall supported green energy growth with ThingWorx. BID Group created flexible solutions for unique needs. Sunbelt Rentals improved fleet management with IoT hardware. Eaton boosted manufacturing with Industry 4.0 technologies.

Company | Use Case | Description |

|---|---|---|

SIG | Energy Optimization | Saved energy and reduced carbon emissions. |

Flowserve | Condition Monitoring | Improved reliability and efficiency. |

The Griffin’s Food Co | Faster Operations | Achieved quicker and scalable processes. |

Vattenfall | Green Energy Growth | Helped grow sustainable energy efforts. |

BID Group | Custom IIoT Solutions | Designed flexible tools for unique needs. |

Sunbelt Rentals | Fleet Management | Improved asset tracking and management. |

Eaton | Manufacturing Transformation | Advanced manufacturing with Industry 4.0 tools. |

Choosing the right hardware for your industry boosts efficiency, automation, and connectivity.

How to Pick the Best IIoT Hardware for Your Needs

Understanding Your Industry’s Needs

Start by knowing what your industry needs most. Each industry, like manufacturing or energy, has unique challenges. Pick hardware that fits your goals and works with your current tools. For example, if you use older machines, choose hardware that connects well with them and supports new systems.

When deciding, think about these important points:

Compatibility: Make sure the hardware works with your current tools. It should connect smoothly with systems like ERP or CRM for easy data sharing.

Scalability: Choose hardware that grows with your business. It should handle more devices and data as you expand.

Data Management: Pick tools that collect and analyze data well. This helps you make smart choices using real-time information.

Security: Look for strong security features to keep your data safe from hackers.

User-Friendliness: The hardware should be simple to set up and use, even for non-tech workers.

Tip: Think about how the hardware can improve your work, like helping with machine repairs in factories or tracking energy use in power plants.

Checking Scalability, Compatibility, and Security

Good IIoT hardware must grow with you, fit your systems, and stay secure.

Scalability: The hardware should handle more sensors or bigger setups as you grow. This avoids needing a full replacement later. Scalable tools help manage more data and keep things running smoothly.

Compatibility: It should work with what you already have. Check if it supports the systems and standards your industry uses. For older machines, find hardware that connects old and new tech for smooth operations.

Security: Strong security is a must. Look for features like encryption and threat alerts. These protect your data and follow industry rules. A secure system keeps your work safe and builds trust.

Note: Balancing these three—scalability, compatibility, and security—keeps your hardware useful as your business grows and faces new challenges.

Thinking About Cost, ROI, and Long-Term Benefits

Buying IIoT hardware needs smart money planning. It might cost a lot at first, but the benefits over time are worth it. Check how much value it will bring back to your business.

Here are some ways it saves money:

Less Downtime and Repairs: It spots problems early, so machines don’t break down. This saves repair costs and keeps work going.

Better Quality and Rules Compliance: Real-time data helps improve product quality and meet rules. This avoids fines and reduces mistakes.

Smarter Inventory: It connects with inventory tools to predict needs better. This stops overstocking and cuts storage costs.

More Flexibility: Quick changes to market demands keep your business competitive.

Data-Driven Choices: Real-time insights help you save money and improve production.

Market Edge: Using advanced hardware makes your business stand out.

Tip: Don’t just look at short-term savings. Think about how the hardware will help your business grow and improve over time. A good choice can make your work faster, smarter, and more connected.

Why Vendor Help and System Integration Are Important

Picking the right IIoT hardware needs good vendor help and system integration. These things make sure your tools work well now and in the future.

Why Vendor Help Is Important

Good vendor help keeps your IIoT tools running smoothly. Vendors who know your industry can solve your problems better. They can help with moving data, setting alarms, and planning workflows. This support reduces delays and helps you reach your goals faster.

Vendors also give updates and fix issues over time. This keeps your tools working with new tech and safety rules. Without this help, your tools might not keep up with changes in the industry.

Why System Integration Matters

System integration makes sure your IIoT tools work with other systems. This includes linking to cloud services, networks, and older machines. Tools that work together create a connected system that improves how things run.

Adding smart tech like AI and machine learning can make your system even better. It can predict problems and give real-time updates. This saves money by stopping breakdowns and boosts productivity.

What to Look for in Vendors and Systems

When choosing vendors and systems, check these points:

What to Check | Why It Matters |

|---|---|

Industry Knowledge | Vendors who know your field can give better solutions. |

Growth Ability | Systems should grow as your business grows. |

Safety | Strong safety features protect your data. |

Compatibility | Tools should work well with what you already have. |

Flexibility | Open systems let you add or change tools easily. |

These points help you pick tools that fit your needs and future plans.

Why Strong Partnerships Help

Working closely with vendors and system providers has many benefits:

Quicker setup and problem-solving.

Better data safety with strong security tools.

Systems that grow with your business.

Access to new tech like AI and cloud tools.

Tip: Pick vendors with open systems and flexible tools. This keeps your IIoT tools useful as your needs change.

By focusing on vendor help and system integration, you can get the most from your IIoT tools. This makes your systems more connected and prepares your business for future success.

IIoT hardware helps industries work better and create new ideas. It links systems, runs tasks automatically, and gives real-time updates. This helps people make smarter choices and keeps workplaces safer. Top tools for 2025, like Siemens SIMATIC IoT2040 and Rockwell FactoryTalk Edge Gateway, have special features. These include edge computing, spotting problems early, and easy connection to IoT systems.

Metric/Benefit | Example/Source | Impact Description |

|---|---|---|

Less Waste | Harley-Davidson’s smart factory | IIoT tools cut material waste, saving money and helping the planet. |

Better Quality Checks | Philips’ healthcare equipment manufacturing | Watching closely keeps quality high and catches problems early. |

Spotting Problems Early | Rolls-Royce’s low-cost IoT trackers | Stops big breakdowns, cutting downtime and improving efficiency. |

Downtime Costs | Average of 800 hours of equipment downtime annually costing $50 billion total | Shows how much money is lost when machines stop working. |

Pick the right IIoT hardware by knowing what your industry needs. Check if it fits with your tools, can grow with your business, and keeps data safe. Think about long-term gains like fewer breakdowns and better products. Working with good vendors makes setup easy and keeps systems ready for the future. Smart choices help you get the most from IIoT hardware.

Tip: Begin with small steps, test the tools, and expand as you grow.

FAQ

What does IIoT hardware do?

IIoT hardware links machines, sensors, and systems to gather data. It helps automate work, track operations, and make better choices. This boosts efficiency, cuts downtime, and increases productivity in industries.

How can I pick the right IIoT hardware?

First, figure out what your business needs. Pick hardware that works with your tools, grows with your business, and keeps data safe. Check for features like easy use, compatibility, and scalability. Choose one that matches your goals.

Can older machines use IIoT hardware?

Yes, many IIoT tools, like Siemens SIMATIC IoT2040, connect old machines to new systems. They act as a link, sharing data without needing new equipment. This makes upgrades cheaper.

Is IIoT hardware safe?

Most IIoT tools have strong safety features like encryption and alerts. These keep your data safe from hackers. Pick devices with good security and regular updates for extra protection.

How does IIoT hardware save money?

IIoT tools spot problems early, cutting downtime and repair costs. They improve product quality and reduce waste. Real-time data helps you work smarter. Over time, these savings make the investment worth it.

See Also

The Importance Of IoT Device PCBA Manufacturing In Today’s World

Navigating ITAR Regulations For PCBA Manufacturing By 2025

Leading Applications Of Through-Hole Technology In 2025 Electronics

The Role Of PCBA In Enhancing Industrial Automation Efficiency

Essential Technologies Shaping PCBA Manufacturing For Today’s Electronics