Choosing between Turnkey PCBA and Consignment Manufacturing can change how you make products. Turnkey PCBA is an all-in-one service. The provider does everything, like getting parts and putting them together. Consignment Manufacturing means you provide the parts. This gives you more control but also more work.

In 2025, picking the right option will be even more important as things change. For example:

Flexible manufacturing needs to solve specific problems easily.

Smarter AI tools make production faster and better.

Custom-made products are more popular as people want unique items.

Eco-friendly goals are changing how factories work to help the planet.

These changes, along with Gartner’s idea that 25% of factories will use flexible systems by 2025, show why choosing carefully matters. Turnkey PCBA is good for simple and easy processes. Consignment Manufacturing works better if you want more control.

Key Takeaways

Turnkey PCBA handles everything, from getting parts to assembly. It works well for projects with tight deadlines.

Consignment Manufacturing lets you control the parts used. This is helpful for projects needing special materials or designs.

Pick the right method based on your project, money, and how much control you want over production.

Learn about trends like automation and eco-friendly practices. This helps your manufacturing stay ready for future needs.

Think about how your project can grow. Turnkey PCBA is good for fast changes, while Consignment Manufacturing is better for custom parts.

Understanding Turnkey PCBA

What is Turnkey PCBA?

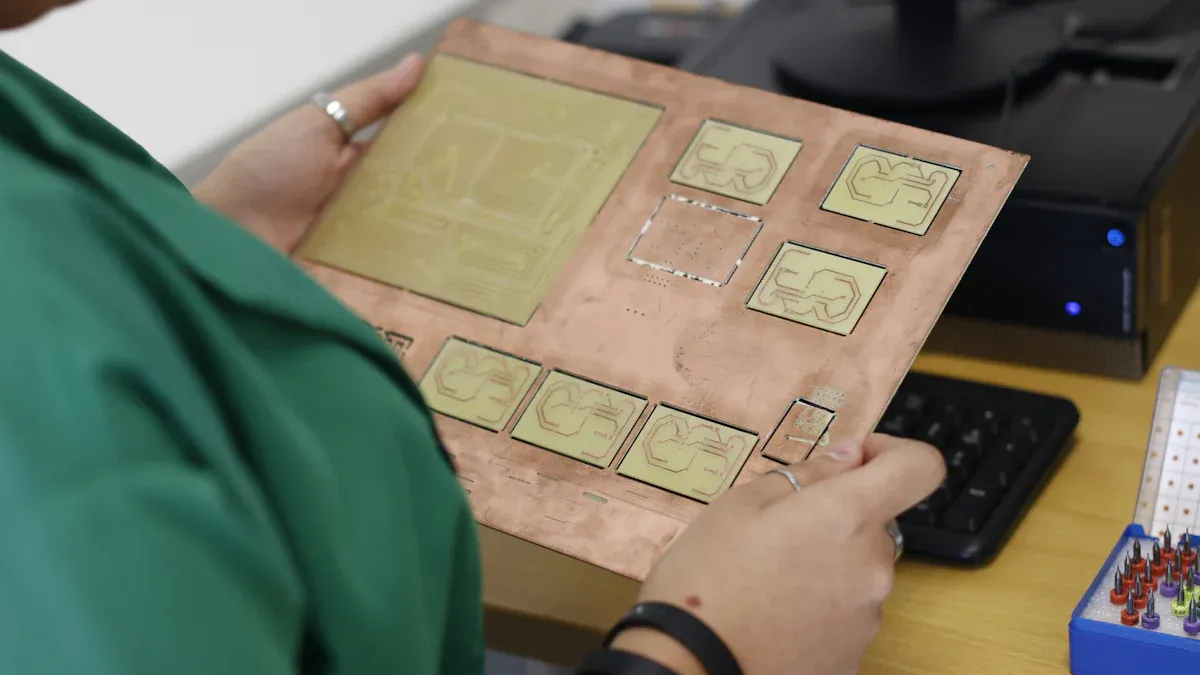

Turnkey PCBA means the provider handles everything for you. They get parts, build the PCB, and check quality. You only need to give them your design files. They take care of the rest. This saves you from dealing with many suppliers or managing parts.

Turnkey services use smart methods to work well and fast. For example, they improve your PCB design to lower costs and make it easier to build. They also use machines to check for mistakes and test in different conditions. These steps make turnkey services trustworthy and effective.

Benefits of Turnkey PCBA

Turnkey PCBA has many benefits. First, it saves time. You can focus on other tasks while they handle production. Second, it cuts costs. Providers buy parts at good prices because of their supplier deals. Third, it ensures great quality. They follow strict checks to deliver reliable products.

Turnkey services also make hard projects easier. For example, in cars, they create strong PCBs for tough conditions. For IoT start-ups, they quickly make samples and plan for bigger production. These features make turnkey services great for industries with big needs.

When to Choose Turnkey PCBA

Pick turnkey PCBA if you want an easy process. If you can’t manage parts or assembly, this is a good choice. It’s also helpful for tight deadlines since they work fast to finish on time.

Turnkey is best for projects needing high accuracy and quality. For example, medical devices need strict rules, and turnkey helps meet them. If your project is complex or uses special parts, turnkey services can help you succeed.

Exploring Consignment Manufacturing

What is Consignment Manufacturing?

In consignment manufacturing, you provide the parts for production. The manufacturer then assembles the product based on your instructions. This method lets you control the materials while using the manufacturer’s skills for assembly.

A consignment agreement explains how this process works. It includes rules for handling, assembling, and returning unused parts. For example, a bookstore might sell books supplied by a publisher under a consignment deal. The store pays only for sold books and returns the rest. Similarly, in consignment PCB assembly, you own the parts until the product is finished or delivered.

Benefits of Consignment Manufacturing

Consignment manufacturing has many benefits for your business:

Increased Market Reach: You can work with different manufacturers to sell more products.

Risk Sharing: You keep ownership of parts, lowering financial risks for both sides.

Real-Time Feedback: Manufacturers share tips to improve your designs during assembly.

Cost Savings: You save money by using parts you already have.

Flexibility: You can change inventory and meet market needs quickly.

For example, consignment PCB assembly helps you manage special parts that are hard to find. This ensures your project meets exact needs without losing quality.

When to Choose Consignment Manufacturing

Choose consignment manufacturing if you want control over the parts used. This is a good option if you have rare or special materials important to your design. It also works well for keeping consistency in multiple production runs.

This method is helpful when you own the parts until the product is sold. For instance, if you make expensive electronics, consignment PCB assembly protects your parts while using the manufacturer’s skills. If your project has tricky logistics or special parts, this method gives you the flexibility to adjust as needed.

Turnkey PCBA vs Consignment Manufacturing: A Comparison

Cost and Budget Considerations

Turnkey PCBA helps you plan costs better. The provider buys parts in bulk, saving money. They also handle suppliers, so you don’t have to. This lowers your expenses and makes budgeting easier. Consignment manufacturing lets you use your own parts. This can save money if you already have stock or discounts. But, it might add hidden costs like storage or shipping.

Turnkey services give one clear price for everything. This is great for small businesses with tight budgets. Consignment manufacturing works well if you need special parts or have unique suppliers. Think about your needs to pick the best option for your budget.

Efficiency and Time-to-Market

Turnkey PCBA is very fast and efficient. They do all the steps in one place, which saves time. This is perfect for industries like electronics, where speed matters. Turnkey providers also improve designs to make production quicker.

Consignment manufacturing gives you control but can slow things down. You need to manage parts and fix supply problems, which takes time. If you’re in a hurry, turnkey services are better. They work faster and deliver products quickly, helping you stay ahead.

Flexibility and Customization

Consignment manufacturing is very flexible. You control the parts and can adjust to changes easily. This is helpful for projects with rare or custom parts. Turnkey PCBA is also improving in customization. Providers now offer more options for specific needs.

For example, some companies use smart tools to cut costs and improve production. Turnkey providers now handle different models on one line and work faster. They’ve improved efficiency by 42%. These updates make turnkey services a good choice for businesses needing both flexibility and speed.

Scalability for Different Project Sizes

Scalability is key when picking between Turnkey PCBA and Consignment Manufacturing. The size of your project, big or small, decides which works better.

Turnkey PCBA is great for all project sizes. Providers can easily adjust production levels. For small projects, they quickly make prototypes or small batches without big upfront costs. For large projects, they use strong supply chains and machines to handle big orders efficiently.

Consignment Manufacturing is flexible for special or unique projects. If you already have parts or need strict material control, this method lets you grow at your own speed. But scaling up can be harder. You’ll need to manage parts, shipping, and suppliers, which can slow things down as demand grows.

Tip: If your project might grow fast or change often, Turnkey PCBA is more dependable. They adjust quickly to meet market needs without delays.

Here’s a simple comparison of scalability:

Factor | Turnkey PCBA | Consignment Manufacturing |

|---|---|---|

Small Projects | Quick and cost-effective | Needs more effort to handle parts |

Large Projects | Smooth and efficient | Can face supply issues |

Flexibility | High, with little management needed | High, but needs active oversight |

The best choice depends on how well you manage resources and plan for growth. Turnkey PCBA makes scaling easy, while Consignment Manufacturing gives control but needs more work.

Quality Control and Accountability

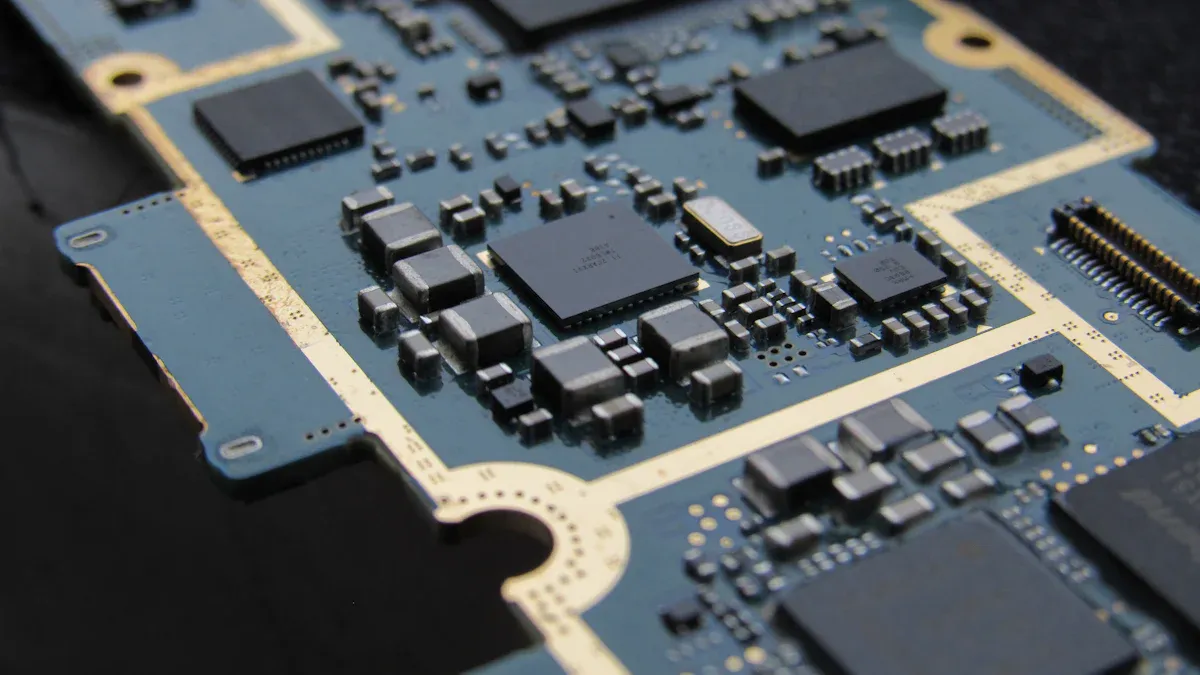

Quality control is very important in PCB assembly. Turnkey PCBA providers take full responsibility for the process. They use smart testing tools like AOI and ICT to find and fix problems before delivery. This ensures the product meets high standards.

In Consignment Manufacturing, quality depends on the parts you provide. While the manufacturer assembles the product, you are responsible for the quality of the materials. If parts don’t meet requirements, it can cause problems.

Note: Turnkey PCBA providers often include warranties, giving you confidence in their work. With Consignment Manufacturing, you’re responsible for part quality, so there’s less assurance.

Turnkey PCBA ensures consistent quality for every production run. Consignment Manufacturing offers control but requires more time and effort for quality checks. If top quality is your goal, Turnkey PCBA is the safer choice.

Trends Shaping PCBA Manufacturing in 2025

Advancements in Automation and AI

Automation and AI are changing how PCBA is made. Robots now assemble parts with great accuracy. This reduces mistakes and improves efficiency. These robots handle repeated tasks perfectly, ensuring high quality. AI also helps improve designs, making production faster and better.

Tools powered by AI predict production needs and cut waste. For example, automated systems manage inventory, while AI finds the best shipping routes. These tools save time and lower costs, helping businesses stay competitive.

Tip: Using AI for quality checks means fewer manual inspections. This makes projects more reliable and quicker to finish.

Sustainability and Eco-Friendly Practices

In 2025, sustainability is a must. New rules like ESPR push for greener methods. Manufacturers now use lead-free solder, recyclable materials, and biodegradable options like polylactic acid.

The industry is also cutting resource use. Energy use may grow by 12% and water use by 8% from 2025 to 2035. To help, factories use low-energy processes and recycling. These steps protect the planet while keeping quality high.

Note: Green practices meet rules and attract eco-friendly customers.

Supply Chain Innovations

Supply chain problems, like part shortages, can slow production. To fix this, companies use better forecasting tools and just-in-time systems. These methods predict needs and avoid delays.

Working with many suppliers also helps keep parts flowing. This ensures steady production even during global issues. These changes help meet market needs and keep production smooth.

Insight: A strong supply chain reduces risks and helps you grow easily.

Evolving Market Demands and Expectations

The PCBA industry is changing fast to meet new needs. To stay ahead, you must understand these changes. The global PCB market was worth $67.9 billion in 2023. By 2029, it may grow to $92.4 billion. This shows how important advanced PCBs are in many industries.

Several things drive this growth:

Autonomous Vehicles (AVs) and Electric Vehicles (EVs): These need advanced PCBs for safety and power systems. As AVs and EVs become common, the need for strong, high-quality PCBs will grow.

Consumer Electronics and IoT Devices: Small, feature-packed devices are very popular. This increases the demand for creative PCB designs to support them.

5G Technology: 5G networks need PCBs that handle high frequencies well. This pushes manufacturers to use better materials and designs.

The PCB Assembly market is also growing. It could rise from $36.86 billion in 2023 to $50.0 billion by 2032. New technologies are shaping this growth:

Surface Mount Technology (SMT): It’s efficient and works well for small designs.

Through-Hole Technology (THT): Used for reliable systems like in defense and aerospace.

Hybrid Technology: Combines SMT and THT for flexible assembly options.

Consumer demands and investments in electronics also affect the market. To succeed, focus on new ideas and adapt to new tech.

Tip: Keep up with these trends to match market needs and grow your business.

Picking between Turnkey PCBA and Consignment Manufacturing depends on your project. Turnkey PCBA handles everything for you. It’s great for fast deadlines and top-quality needs. Consignment Manufacturing lets you control materials. This works well for special projects or if you already have parts.

Turnkey PCBA is good for saving money and getting quick quotes. Consignment Manufacturing is better for unique parts or careful management. Think about trends like automation and eco-friendly practices in 2025. These will help you stay ahead in a fast-changing market.

FAQ

1. What’s the key difference between Turnkey PCBA and Consignment Manufacturing?

Turnkey PCBA does everything, from getting parts to assembly. Consignment Manufacturing means you provide the parts, and they only assemble. Your choice depends on how much control you want and your project’s difficulty.

2. Which option works best for tight deadlines?

Turnkey PCBA is faster for tight deadlines. They handle everything, avoiding delays from sourcing or shipping. This smooth process makes production and delivery quicker than Consignment Manufacturing, where you manage parts.

3. Can I use both Turnkey PCBA and Consignment Manufacturing together?

Yes, you can mix both methods. For instance, use Turnkey PCBA for common parts and Consignment Manufacturing for rare or custom ones. This mix gives flexibility and uses the best of both systems.

4. How do I choose the right model for my project?

Think about your project’s needs. Pick Turnkey PCBA for simplicity, speed, and quality. Choose Consignment Manufacturing if you want control or already have parts. Look at your budget, timeline, and how much you need to scale.

5. Is Turnkey PCBA more costly than Consignment Manufacturing?

Not always. Turnkey PCBA can save money with bulk buying and efficient work. Consignment Manufacturing might cost less if you already own parts. Check your project’s needs and hidden costs like storage or shipping before deciding.

See Also

Achieving Superior Quality Through Effective PCBA Manufacturing Methods

Choosing The Right PCBA Manufacturer To Suit Your Requirements

Simplifying Electronic Assembly Outsourcing For Business Success