When you choose Resonit, you receive highly precise circuit boards. Each board is crafted in strict compliance with international standards, ensuring exceptional quality and performance. That’s why “резонит стабильно” is a name you can rely on. Trust them to deliver products that consistently meet global benchmarks. With Resonit, you are guaranteed stable and dependable results every time.

Key Takeaways

Resonit uses strict global rules like ISO and IPC to make sure circuit boards are high-quality and reliable.

The process includes checking designs, picking good materials, and placing parts carefully to ensure they work well.

Both machine and hand checks find mistakes early, so every board meets quality standards.

Tests for function and tough conditions prove Resonit’s boards can handle real-life use and stay strong.

Picking Resonit means getting safe, planet-friendly products that work worldwide and last a long time.

International Standards Resonit Follows

ISO Standards for Quality and Safety

Resonit uses ISO rules to make safe, high-quality products. These rules help keep the manufacturing process consistent every time. They also make sure each circuit board meets strict global standards. By following ISO rules, Resonit creates products that are safe and reliable for many industries. This shows how much the company cares about doing a great job.

IPC Standards in PCB Assembly

IPC rules are very important for making circuit boards. Resonit uses these rules during every step of production. From designing to putting parts together, IPC rules ensure accuracy. They also help with neat soldering, placing parts, and testing. By using IPC rules, Resonit makes products that meet top industry standards.

Environmental and Safety Practices

Resonit cares about the environment and safety. The company follows global rules to lower its impact on nature. It uses materials and methods that are better for the planet. Safety is also a big focus. Resonit makes sure its work keeps workers and users safe. This matches the company’s goal to make safe and eco-friendly products.

By following these rules, “резонит стабильно” stays a trusted name in the field.

Step-by-Step Assembly Process

Design Validation and Prototyping

A good PCB starts with a strong design. First, the design is checked to meet all needs. This step finds and fixes mistakes in the design. After checking, a prototype is made to test the board. Prototypes help find problems early and save time later. Resonit uses smart tools to make sure prototypes work well. This process ensures the final board works as planned.

Material Selection and Procurement

Picking the right materials is very important for good boards. Resonit gets materials from trusted suppliers who meet high standards.

The team works closely with reliable suppliers.

Suppliers are checked often to ensure quality and on-time delivery.

Materials are chosen to be safe for people and the planet.

These steps make sure every board is strong and eco-friendly. Resonit’s focus on quality shows its promise to make great products. This proves that “резонит стабильно” means reliable and excellent work.

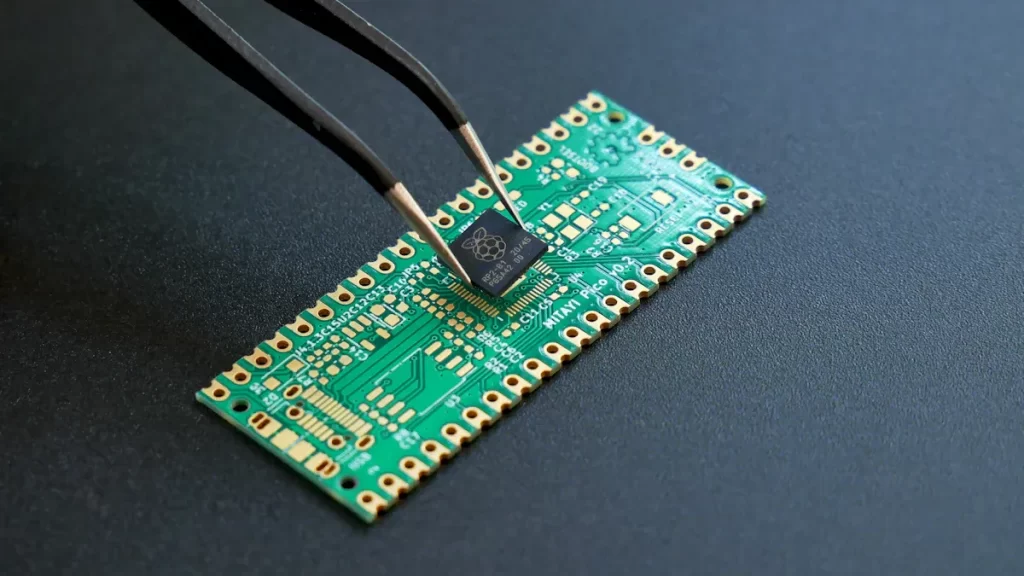

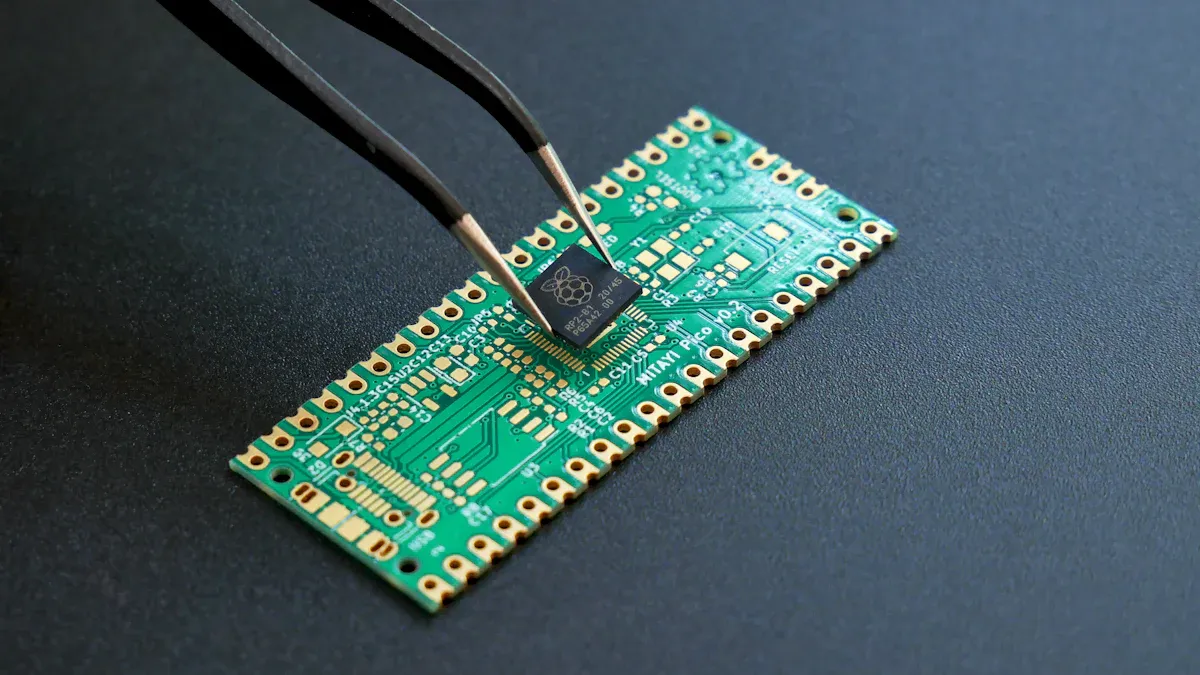

Component Placement and Soldering

Placing parts on a board needs to be exact. Machines are used to put each part in the right spot. These machines follow the design to place parts correctly. After placing, soldering holds the parts tightly to the board. Resonit uses advanced soldering to make strong, lasting connections. This step ensures the board works well and lasts a long time. By being careful and precise, Resonit makes boards that meet world standards.

Inspection and Quality Control

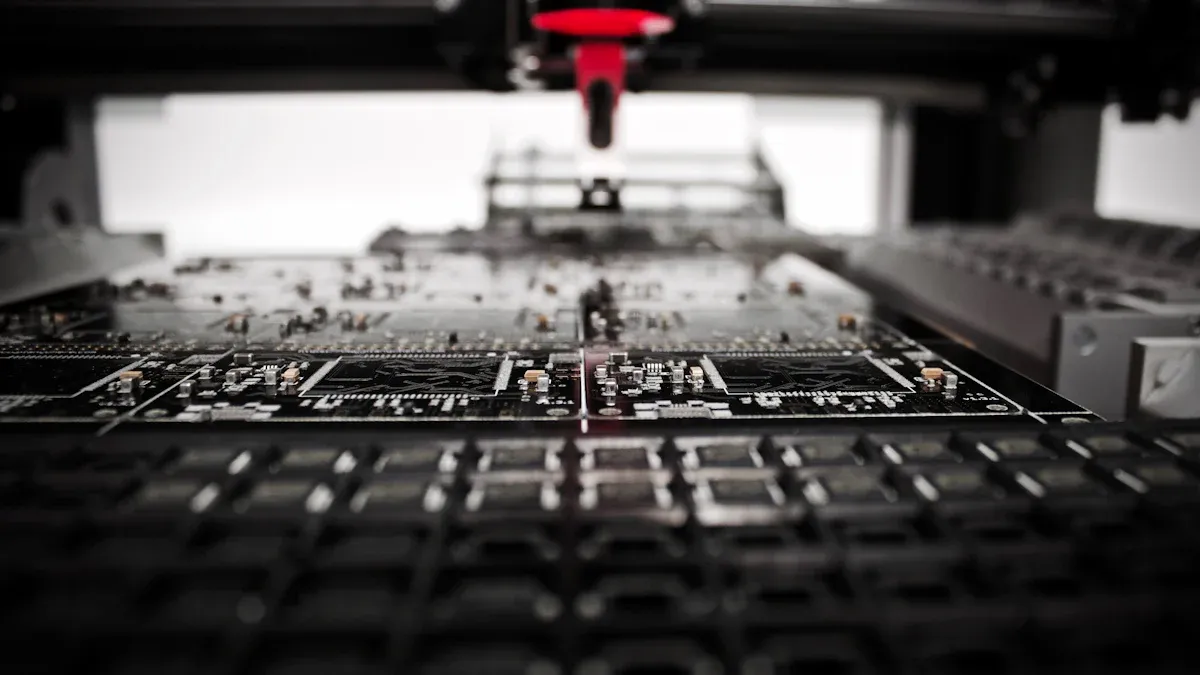

Checking and testing are key to making perfect PCBs. Resonit uses smart methods to find tiny mistakes and ensure great performance. Here’s how they do it:

Automated Optical Inspection (AOI)

Special machines with cameras scan each board. They look for problems like misplaced parts, bad soldering, or missing pieces. This step makes sure every board matches the design exactly.X-Ray Inspection

Resonit uses X-rays for boards with many layers. This lets them check inside the board to see hidden connections. It ensures all layers are correct and free of errors.Manual Inspection

Experts carefully check the boards by hand. They use magnifying tools to spot things machines might miss. This adds extra care to the process.

Tip: Using both machines and people helps catch every mistake.

Electrical Testing

Resonit tests if the board works properly with electricity. This step checks if circuits handle voltage and current without problems.Dimensional Verification

The team measures the board’s size to make sure it fits. This step is important for working well with other parts.

Why Inspection Matters

Inspection is not just about fixing errors. It’s about making sure you get a product you can trust. By finding problems early, Resonit saves time and gives you a strong and reliable PCB产品.

Note: Resonit’s careful checks show their promise to quality. You can count on their boards to always meet your needs.

Quality Assurance and Testing

Functional Testing for Performance

Every PCB产品 must work well in real-life situations. Functional testing checks if the board works as planned. Resonit tests the board in conditions it will face when used. They check how it handles electricity, power, and data without mistakes.

Resonit uses special tools to test performance. For example, they see if the board connects properly with other devices. They also test if it manages the needed voltage and current safely. These steps make sure the PCB产品 works reliably for its purpose.

Tip: Testing early helps fix problems and saves time later.

Environmental Stress Testing

PCBs often deal with tough conditions like heat or moisture. Resonit tests boards to ensure they stay strong. These tests show how the board performs in hard situations.

Here are some tests Resonit does:

Thermal Cycling: The board faces quick temperature changes to check strength.

Humidity Testing: High moisture levels test how well the board resists water.

Vibration Testing: The board is shaken to see if it handles movement.

These tests prove the PCB产品 can work in tough environments. Resonit’s focus on quality shows that “резонит стабильно” means durable products.

Final Inspection and Certification

Before shipping, every PCB产品 gets a last check. This step ensures the board meets all rules and customer needs. Resonit’s team looks closely for any remaining issues.

The final check includes:

Visual Inspection: Experts look for scratches or bad soldering.

Electrical Testing: The board is tested again to confirm it works.

Dimensional Check: Sizes are checked to ensure the board fits perfectly.

After this, Resonit gives a certificate for the PCB产品. This proves the board meets global standards. You can trust Resonit’s products for any industry, showing that “резонит стабильно” means reliable quality.

Benefits of Following International Standards

Reliable and Long-Lasting Products

Picking products made to international rules gives you strong results. Resonit makes sure every PCB产品 follows strict global standards. This means the boards work well for a long time. These rules stop problems like overheating or bad connections.

Resonit’s boards are built to handle tough conditions. Whether for machines or gadgets, they stay reliable. Fewer repairs and replacements save you time and money.

Tip: A dependable product works better and earns trust.

Global Market Compatibility

International standards make Resonit’s boards fit markets everywhere. Their PCBs work in many industries without compliance worries.

Here’s how Resonit helps globally:

Europe’s wireless charging market grows with diverse uses.

Resonit’s boards meet needs across Asia, America, Europe, and Africa.

Their products help businesses compete and expand easily.

Resonit’s boards fit into worldwide systems, giving you an advantage.

Better Safety and Environmental Care

Safety and eco-friendliness are big benefits of global standards. Resonit uses safe materials and methods to protect users and workers. Their PCBs handle electricity safely, avoiding risks like overheating.

Resonit also cares about the planet. They pick materials that are less harmful and manage waste responsibly. This supports global goals for a greener future.

Note: Choosing Resonit means helping safety and the environment.

Resonit makes sure every PCB产品 is accurate and meets world rules. Their boards are made to work well and last long. You can rely on Resonit for products that fit many industries. Their promise to quality shows that “резонит стабильно” means reliable and steady work.

Tip: Picking Resonit means working with a team focused on great results.

FAQ

What makes Resonit’s PCBs different from others?

Resonit follows strict rules like ISO and IPC standards. These rules ensure their PCBs are accurate, strong, and work worldwide. They also use advanced methods and care for the environment. This makes their PCBs dependable for many industries.

Tip: Picking Resonit means getting top-quality products you can trust.

How does Resonit ensure environmental responsibility?

Resonit uses materials that are safe for the planet. They also reduce waste during production to protect nature. By following global eco-rules, they make safer products for people and the Earth.

Can Resonit’s PCBs handle extreme conditions?

Yes! Resonit checks their PCBs in tough situations like heat, moisture, and shaking. These tests make sure the boards stay strong and work well in hard environments.

Note: Their careful testing shows Resonit’s PCBs are made to last.

Are Resonit’s PCBs suitable for global markets?

Yes, they are! Resonit designs their PCBs to meet world standards. This makes them work well in systems everywhere, from Europe to Asia to America.

Why should I trust Resonit for my PCB needs?

Resonit focuses on accuracy, safety, and global rules. They make strong, eco-friendly products you can count on every time.

Emoji: ✅ Resonit = Trustworthy, Strong, and Ready for the World!

See Also

Ensuring High Standards in PCB and PCBA Production

The Role of IPC-A-610 in PCBA Quality Assurance

Understanding the Key Differences Between Prototype and Production PCBs