Solder paste is very important in modern electronics. It is a mix of tiny solder pieces and flux. Flux helps stick parts to circuit boards. It is often used in surface mount technology. This keeps parts firmly attached during assembly.

Knowing how solder paste handles heat and electricity is key. Heat affects how it melts and hardens during production. Its electrical traits help current move smoothly in circuits. These features make solder paste crucial for making dependable electronic gadgets.

Key Takeaways

Solder paste is important for electronics. It mixes tiny metal bits with flux to make strong links on circuit boards.

Knowing how solder paste handles heat, like its melting point and heat strength, helps it work well in hot places.

Picking solder paste that carries electricity well, like ones with silver or copper, makes circuits work better and last longer.

Using solder paste correctly and checking its quality during SMT and reflow soldering is key to building strong electronic devices.

Choosing the right solder paste and stencil makes solder joints better, which improves how devices work overall.

Thermal Properties of Solder Paste

Heat Resistance and Melting Point

Solder paste is very important in making electronics. It must handle high heat during soldering without breaking down. The melting point depends on the metals in the paste. For example, lead-free pastes like SAC305 (made of tin, silver, and copper) melt between 217°C and 221°C. This range helps it work well under heat during manufacturing.

Studies show solder paste stays reliable after heating and cooling cycles. Research on SAC305 and Sn3.5Ag pastes found that solder type and board finish didn’t affect BGA joint reliability. This shows how picking the right solder alloy ensures good performance.

Study Focus | Findings |

|---|---|

Thermal cycling of SAC305 and Sn3.5Ag solders | BGA solder joints stayed reliable regardless of solder type or board finish. |

Intermetallic compound evolution | Studied after heating cycles to understand thermal behavior. |

You should also think about how solder paste handles stress at high temperatures. Lead-free pastes lose strength when heated up to 200°C. This is important for electronics used in cars or airplanes, where heat resistance matters.

Study Focus | Findings |

|---|---|

Mechanical properties of lead-free solders | Strength drops at high temperatures (up to 200°C). |

Stress-strain testing | Tested under different conditions to check heat performance. |

Thermal Conductivity in Heat Dissipation

Thermal conductivity shows how well solder paste moves heat away. Good heat transfer stops parts from overheating and breaking. High-conductivity solder paste spreads heat evenly across the circuit board.

Silver-based solder pastes are great for handling heat. They are used in tiny electronic parts where heat control is very important. Research supports silver-based pastes for their excellent heat-handling abilities, making them a top choice for tough jobs.

Study Focus | Findings |

|---|---|

Ag-based solder technology | Works well for high-heat microelectronics, showing strong thermal traits. |

Choosing the right solder paste improves your device’s heat performance. This keeps circuits working well, even in tough conditions.

Electrical Properties of Solder Paste

Electrical Conductivity in Circuit Performance

Electrical conductivity shows how well solder lets electricity flow. Good conductivity helps devices work smoothly and without problems. If the solder has poor conductivity, circuits might fail or stop working.

The metals in solder paste affect how well it conducts electricity. Pastes with silver or copper are great for strong electrical connections. These metals help circuits work better and more reliably. For high-performance gadgets, pick solder paste with excellent conductivity.

Studies prove that solder paste affects how reliable circuits are. Research on lead-free solders like SAC305 and SAC_Q shows this clearly. High heat can weaken their properties, but adding bismuth (Bi) to SAC_Q helps. This mix improves performance under heat, making circuits more dependable.

Insulation Resistance and Reliability

Insulation resistance stops electricity from leaking between circuit parts. High resistance keeps circuits safe from short circuits or damage.

Low insulation resistance can harm your device’s reliability. Leaks can cause circuits to act strangely or break permanently. To avoid this, use solder paste with strong insulation resistance.

Reliability depends on how well solder resists wear in tough conditions. Heat or humidity can weaken its insulating ability over time. Special solder with added materials can handle these challenges better. Choosing such solder ensures your devices stay stable for a long time.

Applications of Solder Paste in Electronics

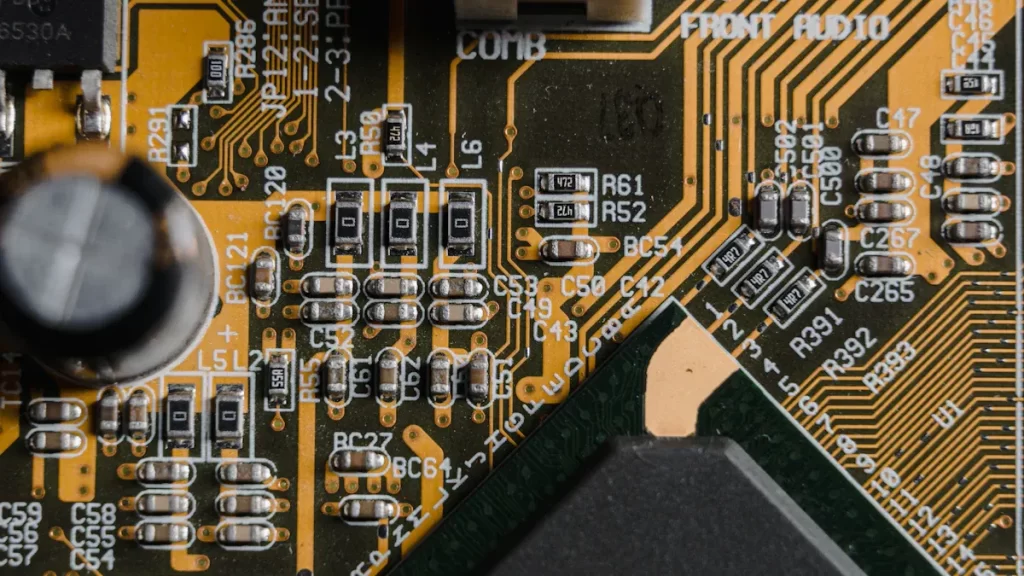

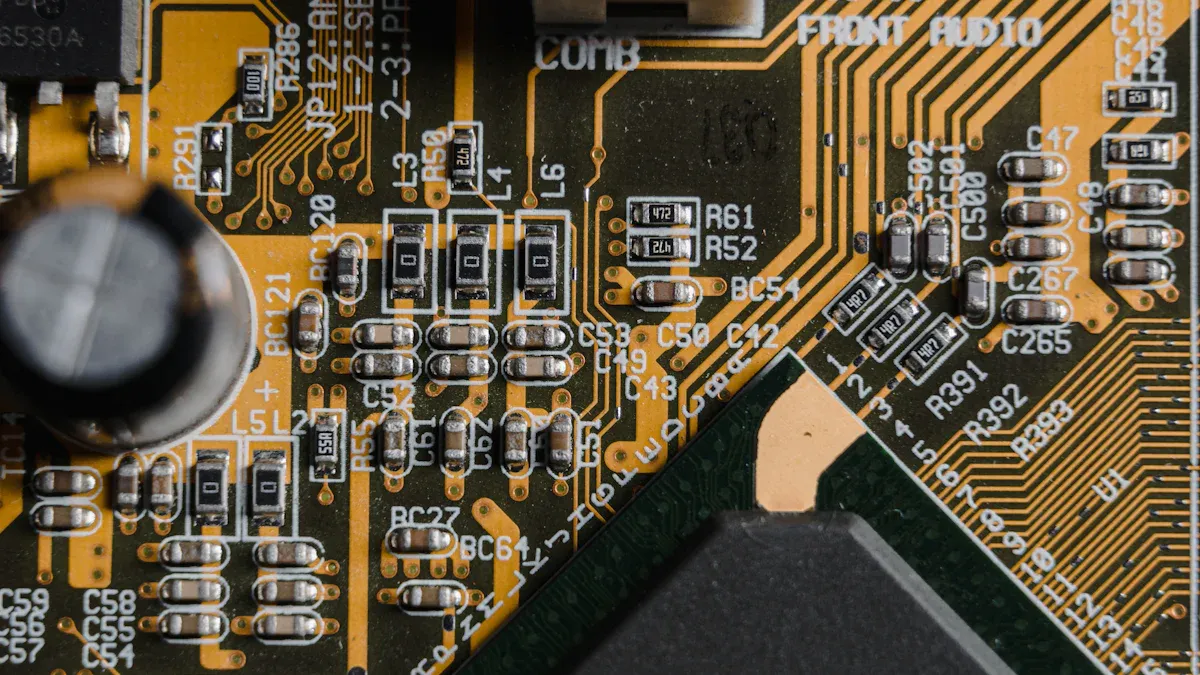

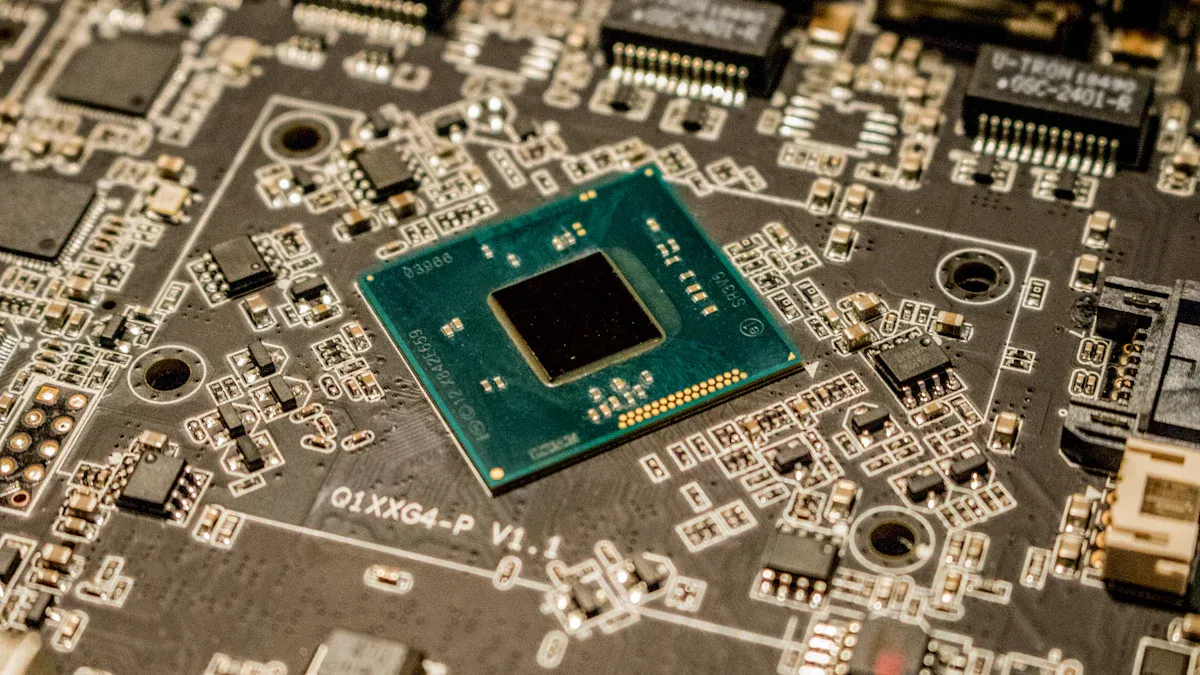

Surface Mount Technology

Surface Mount Technology (SMT) depends on solder paste for assembly. Solder paste helps stick parts onto circuit boards directly. This method removes the need for wires, making gadgets smaller and better. Automated Optical Inspection (AOI) checks solder paste quality in SMT. AOI systems lower false alarms by 18% while keeping perfect recall. This smart system finds defects and ensures strong solder joints.

Important SMT steps include applying solder paste, reflow soldering, and testing. Each step affects how reliable your product will be. Quality checks like X-ray and AOI find hidden problems and confirm solder paste works well.

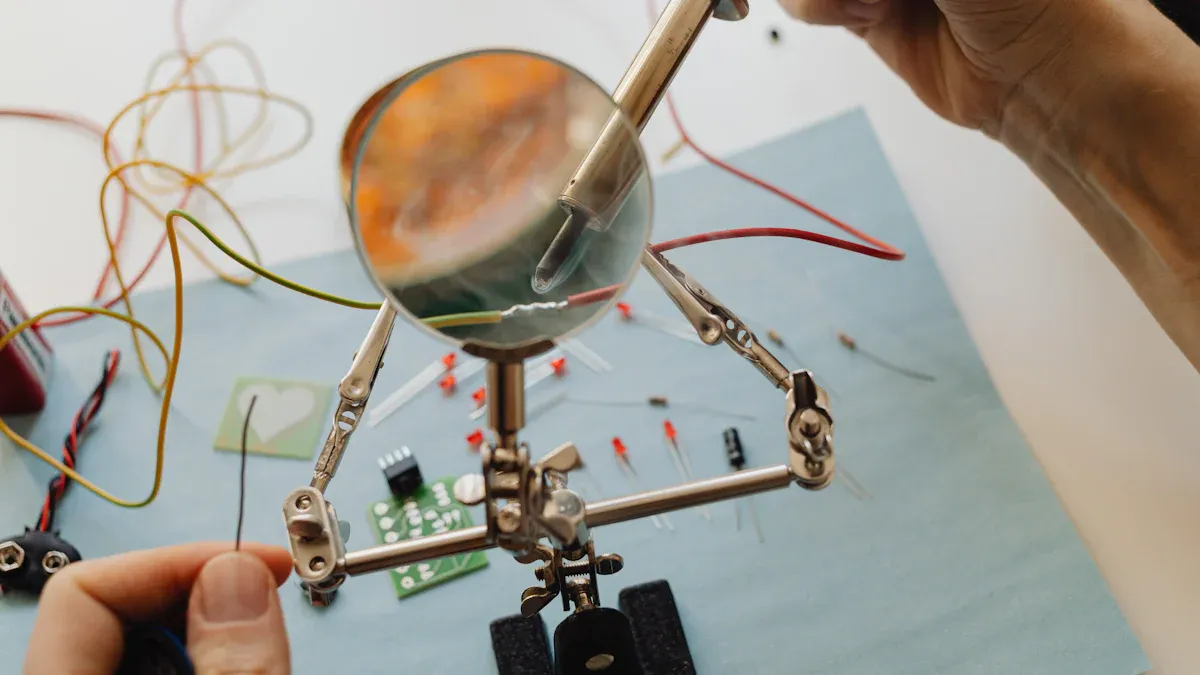

Reflow Soldering Process

Reflow soldering is a key part of making electronics. First, solder paste is applied to the board using a stencil. The paste’s thickness and mix must be just right. After placing parts, the board goes into a reflow oven. Heat melts the paste, forming strong joints that hold parts in place.

Step | Description |

|---|---|

1 | Solder paste is carefully applied to the board using a stencil. |

2 | Heat in the reflow oven melts the paste, securing components. |

This process keeps solder paste working well, even for tricky designs. Adjusting the reflow heat profile helps make joints that handle stress.

Industries and Devices Using Solder Paste

Solder paste is used in many industries and devices. It’s important for electronics, cars, and advanced lighting systems. Mini and microLEDs show the growing need for solder paste in new tech.

Different stencils improve solder paste use for special tasks. Frameless stencils help place SMT parts, and nano-coated ones apply paste precisely. Electroformed stencils work for tiny circuits, while laser-cut stencils are great for prototypes.

The report “Global 3D Solder Paste Inspection Machine for PCBs Market 2025” looks at market trends and competition. It shows how solder paste is used in many areas.

Picking the right solder paste and stencil is very important. It helps make strong, long-lasting solder joints and better devices.

Knowing how solder paste handles heat and electricity is important. It helps you pick the best option for your projects. Solder paste resists heat and conducts electricity well. This makes devices work reliably without problems. It also helps make strong connections and stops circuits from failing. If you use surface mount technology or reflow soldering, the right solder is key. Choosing and using solder paste correctly improves your device’s quality and performance.

FAQ

What is solder paste made of?

Solder paste is a mix of tiny metal bits and flux. Flux cleans surfaces and helps parts stick during soldering. The metal bits create strong electrical and physical connections.

How do you store solder paste?

Keep solder paste in a cool, dry spot, like a fridge. The best temperature is between 0°C and 10°C. Seal it tightly to stop it from drying out. Always follow the maker’s storage rules.

Can solder paste expire?

Yes, solder paste can go bad over time. Its quality gets worse, which affects how it works. Check the expiration date and don’t use old paste for good results.

How do you apply solder paste?

Solder paste is applied with a stencil and a squeegee. The stencil helps place it exactly where it’s needed. In factories, machines often do this step.

Why is solder paste important in electronics?

Solder paste helps make strong electrical connections. It keeps parts firmly attached to circuit boards so devices work properly.

See Also

Precision Soldering Methods for Today’s PCB Assembly Needs

Understanding Surface Mount Technology: A Simple Guide

Achieving High-Quality PCBA Through Expert Manufacturing Techniques