Industrial IoT hardware solutions encompass devices utilized in factories and various industries. These solutions connect machines, gather data, and automate tasks, significantly enhancing operations by enabling real-time tracking and faster decision-making. For example, industrial IoT hardware solutions can foresee issues early, reducing unexpected machine downtime by up to 36%, which saves money and boosts productivity.

By employing these tools, physical machines are linked to digital systems. This connection aids in conserving energy, minimizing waste, and improving efficiency by up to 28.5% within the first year. The Internet of Things transforms industrial environments into smarter and more effective spaces.

Key Takeaways

Industrial IoT hardware helps by linking machines, collecting data, and automating work. This boosts efficiency and productivity.

IoT sensors are important for checking machines and environments. They find problems early and prevent expensive delays.

Gateways and edge devices handle data nearby. This saves internet use and allows quicker decisions, which is key for modern industries.

Predictive maintenance with IoT devices can cut repair costs by 35%. It also makes machines more reliable and keeps things running smoothly.

Picking strong and compatible IoT hardware ensures it lasts long. It also fits well with current systems and supports future growth.

Key Types of Industrial IoT Hardware

Industrial IoT hardware helps turn old industries into smart systems. These tools collect data, automate tasks, and make work more efficient. Below are the main types of IoT hardware used in industries.

IoT Sensors

IoT sensors are key parts of industrial IoT systems. They collect important data from machines and environments. This data helps monitor and make decisions quickly. Different sensors are made for specific jobs:

Temperature sensors: Check heat levels to stop overheating and keep quality.

Proximity sensors: Spot objects nearby, useful in robots and assembly lines.

Pressure sensors: Measure gas or liquid pressure to ensure safety and efficiency.

Did you know? IoT sensors reduce mistakes, improving product quality and cutting defects. They also predict problems early, avoiding costly repairs. For instance, real-time sensor data boosts productivity and lowers costs.

The industrial IoT market, worth $194.4 billion in 2024, may grow to $286.3 billion by 2029. This shows more industries are using IoT sensors.

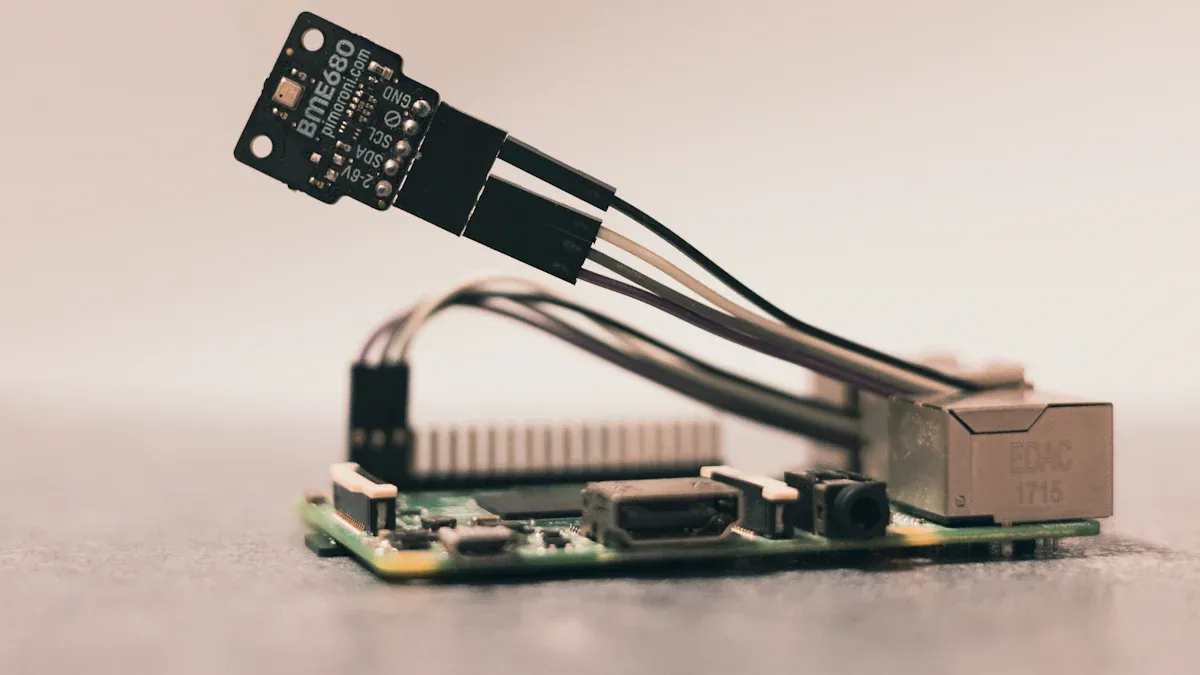

Gateways and Edge Devices

Gateways and edge devices link sensors to cloud systems. They process data locally, cutting down on cloud use. This saves internet bandwidth and improves system speed.

Gateways: Gather data from sensors and send it to servers or clouds. They ensure safe and steady data sharing.

Edge devices: Handle data on-site, allowing faster decisions without cloud help.

Metric | Result |

|---|---|

Bandwidth savings | 30-40% less usage |

Cloud storage optimization | 45% lower costs |

Downtime reduction | 30-50% fewer delays |

Maintenance cost savings | 40% less spending |

Using gateways and edge devices improves IT systems and saves energy. They are vital for modern Industry 4.0 setups.

Connectivity Modules

Connectivity modules let IoT devices talk to each other. They use different communication methods to fit your needs.

Range: LoRa works up to 15 km, while 4G and 5G cover longer distances.

Data transfer rate: 5G is super fast, great for big data. LoRa and NB-IoT are slower but save power.

Power consumption: LoRa, NB-IoT, and Sigfox use little power, ideal for battery devices.

Tip: Pick a module based on range, speed, and power needs. For example, 5G is best for fast data, while LoRa is great for long-range, low-power use.

The IoT connectivity market could reach $391.8 billion by 2028, growing fast at 21.6% yearly. This shows how important strong connections are for industrial IoT systems.

Actuators and Controllers

Actuators and controllers are key parts of industrial IoT systems. They work together to make processes automatic, accurate, and efficient. Actuators handle movements, while controllers manage machines with precision. Together, they create smooth automation in industries.

Actuators turn electrical signals into physical actions. For example, they open valves, move robotic arms, or adjust conveyor belts. These devices are crucial for tasks needing mechanical motion. Controllers, however, process sensor data and send commands to actuators. This teamwork automates complex tasks and reduces manual work.

Controllers often work with advanced tools like PLCs, SCADA, and HMIs. These systems help monitor and control processes in real time. For instance, a PLC can read sensor data and tell an actuator to change a machine’s speed. This automation saves time and lowers mistakes.

The market for process automation control may hit $78.32 billion by 2024, showing its rising demand.

Sensors and actuators are essential for real-time data and efficiency.

Advanced controllers improve workflows and boost connectivity in industries.

Using actuators and controllers makes processes faster and more accurate. These tools are central to modern IoT systems, driving progress and changing industries.

Tip: Choose actuators and controllers that match your current IoT setup. This ensures smooth integration and better automation results.

Applications of Industrial IoT Devices

Industrial IoT devices are changing how industries work. They make processes smarter and more efficient. These devices are used in many areas, like factories and energy management. Below are ways IoT devices are improving industries.

Manufacturing and Production Monitoring

IoT devices have changed how factories run. They give real-time updates on machines and production. Sensors track machine health, find problems early, and keep things running smoothly. This reduces downtime and boosts productivity.

The U.S. industrial IoT market grows 12% yearly. It may reach $1.3 trillion by 2032.

IoT helps manufacturers grow revenue by 28.5%. Productivity increases by 12% with IoT tools.

Real-time data helps spot issues in production lines. For example, air quality sensors ensure safe factory conditions. Using IoT devices improves efficiency and product quality.

Tip: Install IoT systems like HVAC monitors to keep indoor air clean. This creates a healthier workplace and saves energy.

Supply Chain and Logistics Optimization

IoT devices are key for better supply chains and logistics. They track goods in real time, helping avoid delays. Asset trackers show where items are and their condition.

Improvement Type | Percentage Improvement |

|---|---|

Inventory Accuracy | 70% |

Reductions in Theft and Loss | 30% |

Decreases in Manual Counting | 65% |

IoT automates tasks and reduces errors in supply chains. For example, tracking systems ensure shipments arrive on time. These tools save money and make supply chains more efficient.

Did you know? IoT can predict demand trends using real-time data. This helps manage inventory better and avoids overstocking or running out.

Energy Management and Smart Grids

IoT devices are improving energy use and smart grids. They track energy usage and find waste. IoT systems adjust energy flow based on demand.

IoT improves energy efficiency with real-time data analysis.

Predictive tools prevent downtime and cut energy loss.

Smart energy IoT helps industries become more sustainable.

IoT devices lower energy waste and costs. Smart grids powered by IoT are transforming the energy sector. They help industries manage energy smarter and greener.

Tip: Use IoT for HVAC monitoring to save energy and money. This also helps reduce your carbon footprint.

Predictive Maintenance and Equipment Monitoring

Predictive maintenance is changing how industries manage machines. It uses IoT devices to check machine health and predict problems early. Sensors collect real-time data to spot issues before they cause downtime.

Note: Predictive maintenance lowers repair costs by 25% to 35%. It can save up to 40%, making it very cost-effective.

With predictive tools, you learn how machines are performing. This helps plan repairs only when needed, avoiding extra work. For example, vibration sensors find unusual movements, showing when a fix is required. This keeps machines running smoothly and reliably.

Benefits of Predictive Maintenance:

Cost Savings: Predictive maintenance gives back ten times your investment.

Improved Efficiency: Real-time checks reduce downtime and keep production steady.

Enhanced Safety: Finding faults early prevents accidents from broken equipment.

Feature | Benefit |

|---|---|

Real-time monitoring | Quicker problem detection |

Data-driven insights | Better repair planning |

Reduced downtime | More productivity |

IoT devices are key for predictive maintenance. They gather data from machines to help make smart choices. For instance, temperature sensors warn about overheating, so you can fix it fast.

Tip: Use IoT with advanced tools to get the most from predictive maintenance. This saves money and makes your machines last longer.

Switching to predictive maintenance improves operations and cuts costs. It helps industries move from fixing problems after they happen to stopping them before they start. This keeps processes smooth and efficient.

Key Features to Look for in Industrial IoT Hardware

Durability and Ruggedness

Industrial IoT hardware must handle tough conditions. These devices work in extreme heat, cold, and vibrations. Makers test them carefully to ensure they last. For example, they check for interference, surges, and radiation issues. Products follow strict ISO 9001 standards for quality and reliability.

Testing Aspect | What It Checks |

|---|---|

Environmental Testing | Looks for problems like interference, surges, and radiation disturbances. |

Compliance Standards | Makes sure products meet industrial rules before use. |

Continuous Operation Tests | Confirms devices can run nonstop in real-world conditions. |

Longevity and Reliability | Ensures devices work well for years in tough environments. |

These devices can handle temperatures from -40°C to 85°C. They also go through power tests to keep data safe. This toughness ensures they work well even in hard situations.

Tip: Pick hardware made for your industry to avoid breakdowns and extra costs.

Connectivity Options (e.g., Wi-Fi, Cellular, LPWAN)

Good connections are key for sharing data quickly. Industrial IoT hardware offers different ways to connect. LoRa and NB-IoT are great for long-range and low-power needs. LoRa uses very little power and works up to 20 km away. NB-IoT uses cell networks for reliable and fast data.

Wi-Fi: Works well for short distances and fast data.

Cellular (4G/5G): Best for long-distance and high-speed communication.

LPWAN (LoRa, NB-IoT): Ideal for saving energy and working far away.

LoRa saves battery life, while NB-IoT gives better service quality. Choose the right connection based on how far, fast, and efficient you need it to be.

Did you know? LPWAN is cheap and saves energy, making it great for future IoT systems.

Processing Power and Edge Computing Capabilities

Strong processors help handle lots of data fast. Many IoT devices now use edge computing. This means they process data nearby instead of sending it to the cloud. It makes systems quicker, saves internet use, and improves response times.

Statistic | Benefit |

|---|---|

Faster Response Times | Edge computing speeds up responses by 60%. |

Lower Bandwidth Costs | Cuts internet costs by 30–70%. |

Better Production Efficiency | Improves factory work by 20–30%. |

Less Downtime | Reduces delays by 40% with edge computing. |

Edge computing helps make decisions instantly, which is great for automation. For example, 70% of smart factories use edge computing to boost efficiency.

Tip: Choose devices with strong processors and edge computing to save money and improve performance.

Scalability and Compatibility with Existing Systems

Scalability and compatibility are key when picking Industrial IoT hardware. These features help your system grow and work smoothly.

Scalability means your IoT system can expand as needed. For instance, adding more sensors or devices is easy with scalable hardware. You won’t need to replace the whole system. This saves both time and money while supporting future growth. Scalable systems also handle more data without slowing down, even as operations grow bigger.

Compatibility ensures your IoT devices work with what you already have. Following industry standards like MQTT or OPC UA helps devices from different brands communicate well. This makes setup easier and avoids problems with mismatched devices. It also lets you focus on improving your processes.

Feature | Benefit |

|---|---|

Scalability | Lets systems grow easily without big changes or extra costs. |

Compatibility | Ensures devices from different brands work together smoothly. |

Tip: Choose hardware that uses open standards. This keeps your system flexible and ready for the future.

Picking scalable and compatible hardware helps your system adjust to changes. It reduces downtime, saves money, and keeps your operations running efficiently.

Examples of Popular Industrial IoT Devices

IoT Sensors for Environmental Monitoring

IoT sensors are important for tracking environmental conditions in industries. They collect real-time data to save energy and protect resources. For example, energy sensors find waste and help save power. Soil moisture sensors stop overwatering, improving crops and saving water. Fire sensors check temperature, smoke, and humidity to detect fires early. Flood sensors track rainfall and water levels to predict floods.

Other uses include noise tracking for city planning and better waste management. For instance, waste bin sensors show when bins are full, helping plan pickups and save fuel. Greenhouse gas sensors find harmful gases like methane, helping fight climate change.

Application | How It Helps |

|---|---|

Energy Efficiency | Sensors track energy use, helping reduce waste and save power. |

Soil Moisture Monitoring | Real-time data stops overwatering, saving water and improving crops. |

Fire Detection | Sensors find fires early by checking smoke, heat, and humidity. |

Flood Monitoring | Tracks rainfall and water levels to warn about possible floods. |

These sensors help industries save money, make better choices, and protect the planet.

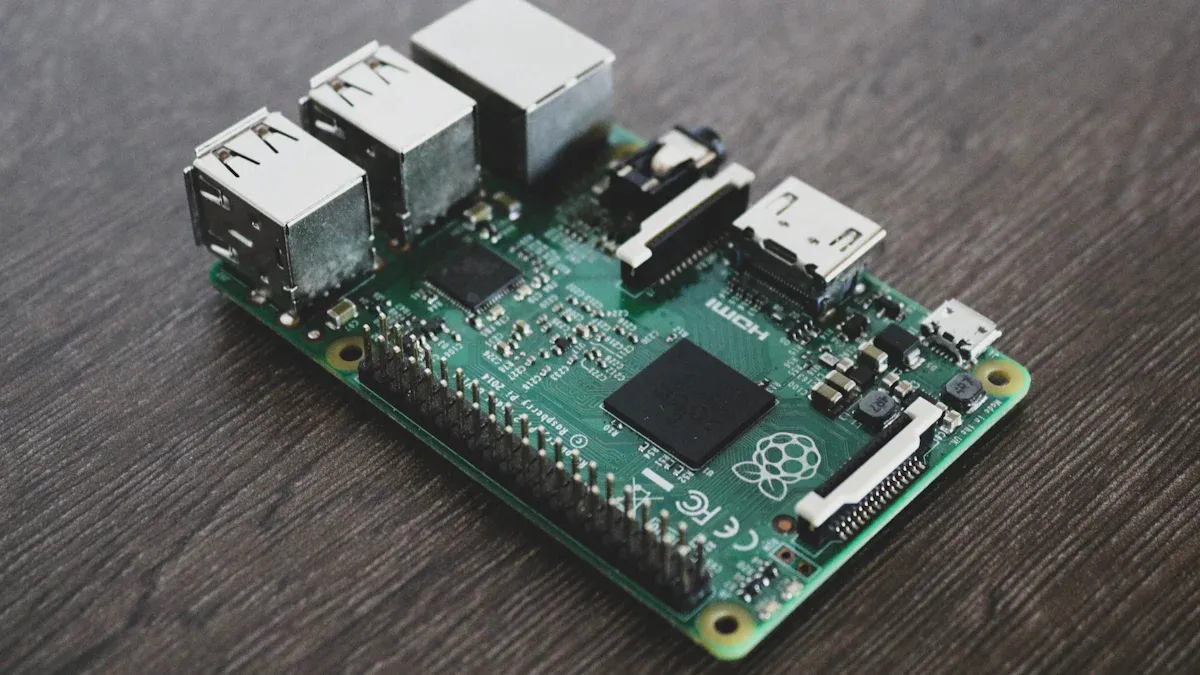

Gateways for Data Transmission

Gateways send data between IoT devices and cloud systems. They make communication smooth and improve how systems work. For example, gateways support protocols like Modbus, making data sharing easier. Remote features let you update systems without being there, saving time and effort. Gateways also connect with cloud systems, making setup faster.

Gateways process data locally, cutting delays and saving internet use. They also work well in remote areas using cellular networks. These features make gateways essential for big IoT projects.

Feature | Benefit |

|---|---|

Supported Protocols | Works with Modbus and OPC UA for smooth communication. |

Remote Management | Updates and fixes can be done without visiting the site. |

Easy Cloud Integration | Connects easily to cloud systems, saving setup time. |

Local Data Processing | Processes data nearby, reducing delays and saving bandwidth. |

Cellular Connectivity | Keeps systems running in remote areas with reliable connections. |

Gateways make IoT systems faster, more reliable, and easier to manage.

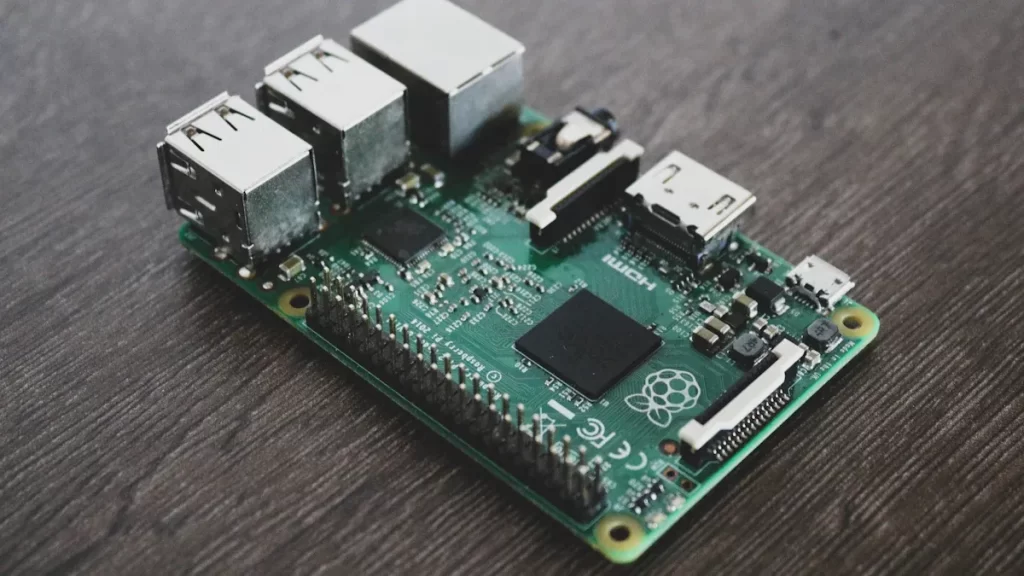

Edge Devices for On-Site Data Processing

Edge devices handle data close to where it is created. This allows quick analysis and faster decisions. They reduce the need to send all data to central systems, saving money and improving speed. For example, edge devices analyze data on-site, helping industries like factories and shipping make quick choices. Each device processes its own data, making it easier to add more devices.

Using edge devices lowers costs for storing and processing data. They can grow with your system without slowing it down. These devices are great for industries needing fast actions, like fixing machines before they break or running smart factories.

Quick data analysis. Data is processed near its source, giving fast results.

Scalable systems. Each device handles its own data, making it easy to add more.

Lower costs. Edge devices reduce expenses for storing and processing data elsewhere.

Edge devices help industries act faster, work better, and save money.

Connectivity Modules for Industrial Networks

Connectivity modules help industrial networks by linking IoT devices. They make sure data moves smoothly, supporting quick decisions and actions. In busy industries, strong networks are key to keeping things running well.

These modules can be adjusted for different industrial needs. This means they work for various tasks and conditions. For example, structured cabling keeps systems neat and easy to test. It also supports fast systems, handling more data and staying reliable.

Sharing data in real time is another important feature. It helps machines make quick decisions and work better. This reduces delays and improves performance. For instance, in factories, connectivity modules let IoT devices talk instantly, keeping production lines running smoothly.

When choosing connectivity modules, check if they work with your current systems. Modules that use protocols like Modbus or OPC UA are easier to connect. They also make networks more dependable. Structured cabling helps transfer data quickly, even as data needs grow.

Using good connectivity modules boosts your industrial network’s performance. They improve communication and allow IoT systems to grow. This keeps your operations efficient and ready for future changes.

Industrial IoT hardware helps industries work better and smarter. These tools watch machines all the time, cutting downtime and improving work. For instance, sensors check how machines are doing right away. This lets you fix problems fast, stopping mistakes and saving resources.

Note: By 2025, most IoT systems will use real-time machine learning. This will make operations smarter and need less human work.

The future of IoT hardware is bright. The market might grow from $213.5 billion in 2025 to $432.6 billion by 2034. As more industries use smart tools, IoT hardware will improve connections. It will help make better choices using data and open new ways to grow.

FAQ

What do IoT sensors do in industries?

IoT sensors gather live data from machines and surroundings. This data helps track operations, find problems early, and boost efficiency. For instance, temperature sensors stop overheating, and pressure sensors keep pipelines safe.

Tip: Use IoT sensors to avoid delays and make better products.

How do gateways and edge devices help IoT systems?

Gateways and edge devices handle data nearby before sending it online. This saves internet use and makes decisions faster. Gateways securely share data, while edge devices allow instant analysis.

Note: These tools are crucial for industries needing fast and steady systems.

Why is strong hardware important for industrial IoT?

Industrial IoT devices work in tough places like extreme heat or vibrations. Strong hardware works well and lowers repair costs. For example, rugged devices can handle -40°C to 85°C temperatures.

Did you know? Tough devices last longer, cutting replacement expenses.

What are the advantages of predictive maintenance with IoT?

Predictive maintenance uses IoT sensors to check machine health. It spots problems early, avoiding breakdowns. This saves repair money, improves safety, and makes machines last longer.

Advantage | Benefit |

|---|---|

Lower repair costs | Cuts 25-35% of expenses |

Less downtime | Increases productivity |

Better safety | Stops accidents |

How do connectivity modules help IoT systems?

Connectivity modules let IoT devices talk to each other. They use Wi-Fi, LoRa, or 5G for different tasks. For example, LoRa is great for long-range, low-power needs, while 5G is perfect for fast data.

Tip: Pick a module based on your distance, speed, and power needs.

See Also

Best Industrial IIoT Hardware Innovations to Expect in 2025

Enhancing Manufacturing Productivity Through IIoT Device Integration

The Importance of PCBA Manufacturing for IoT Devices Now

Key Trends Influencing PCB Assembly in Industrial IoT for 2025

The Role of PCBA in Enhancing Industrial Automation Efficiency