When discussing electronics, the comparison of PCB vs PCBA often arises. A PCB, or printed circuit board, serves as the foundational base of electronic devices, consisting of layers of metal and other materials. On the other hand, a PCBA, or printed circuit board assembly, includes all the components mounted onto the PCB, transforming it into a functional product.

Understanding the distinction between PCB vs PCBA is crucial in the electronics manufacturing process. The global PCB market is projected to grow from $75 billion in 2021 to $120 billion by 2030. Approximately 70% of PCBs are utilized in devices such as smartphones and computers. As technology advances, recognizing how PCBs contribute to PCBAs is essential for improving design and production efficiency.

Key Takeaways

A PCB is a flat board that links electronic parts. A PCBA is a PCB with parts added, so it works.

Knowing the difference between PCB and PCBA helps in making and designing electronics.

Picking good materials and assembly methods can save money and improve how well PCBs and PCBAs work.

Planning time and costs for production is key to avoid delays and keep quality high in electronics projects.

PCBs and PCBAs are used in many fields like cars, healthcare, and communication, showing their value in today’s technology.

What is a PCB?

Definition of PCB

A PCB产品, or printed circuit board, is the base of most electronics. It holds and connects electronic parts together. Think of it as a flat board made of fiberglass or similar material. Thin copper lines on it act like roads for electricity to travel. Without a PCB产品, modern gadgets wouldn’t work well.

The idea of the PCB产品 started in the 1940s. In 1948, the U.S. approved PCBs for commercial use, leading to their popularity. New ideas like plated through-hole technology in 1963 and multilayer PCBs in the 1960s improved their design and use.

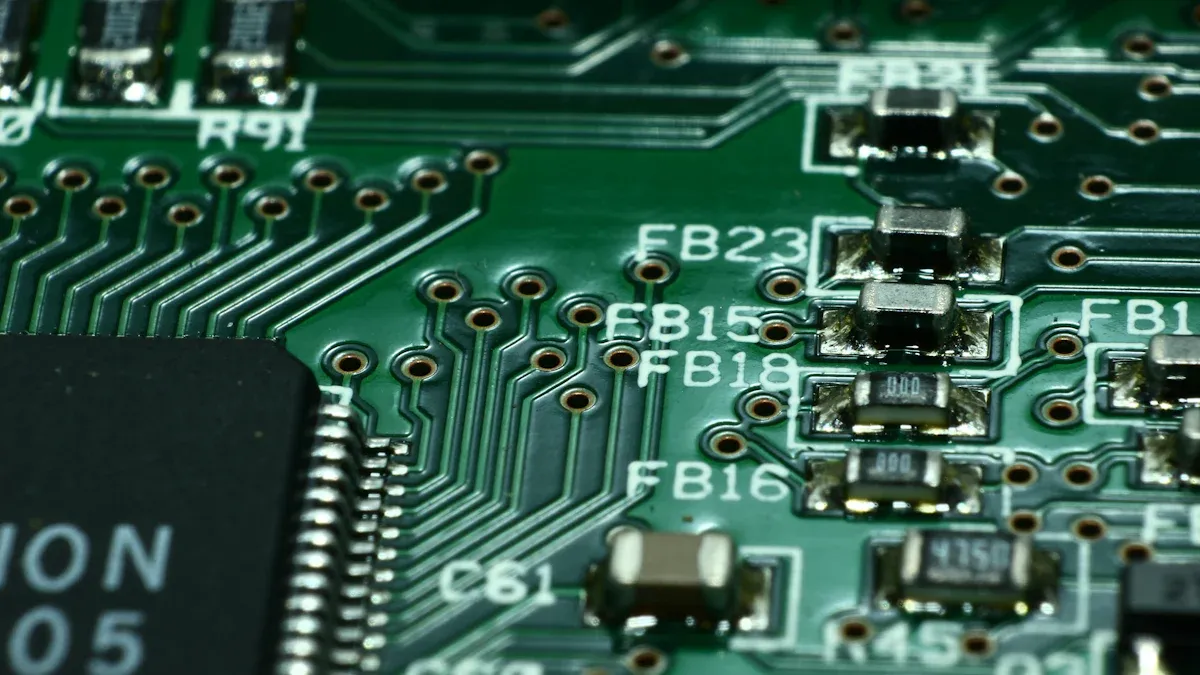

Construction and Materials

A PCB产品 has layers, each with a job. The bottom layer, often fiberglass or epoxy resin, gives support. A copper layer on top carries electricity. A solder mask covers the copper to stop short circuits and protect it. Lastly, a silkscreen layer adds labels to help with assembly.

The materials used depend on the PCB’s purpose. For example:

FR4: A common fiberglass material for general use.

Metal-core PCBs: Use aluminum or copper cores to handle heat, great for LED lights.

Flexible PCBs: Made from polyimide, they can bend, perfect for wearables.

Types of PCBs

There are different types of PCBs, each for specific uses:

Single-sided PCBs: Copper lines are on one side only. They are simple and cheap, used in home devices.

Double-sided PCBs: Copper lines are on both sides, linked by small holes. Found in cars and factory machines.

Multilayer PCBs: Have many layers of copper and insulation. Used in complex devices like phones and computers.

Rigid PCBs: Hard and durable, often used in medical tools.

Flexible PCBs: Can bend and fold, great for small gadgets.

Rigid-flex PCBs: Mix of hard and flexible parts, used in military and space tech.

PCB产品 technology has come far. For example, Motorola made double-sided boards with electroplated holes in 1953. This led to today’s advanced multilayer PCBs. Now, PCBs are vital in almost every field, from home gadgets to military systems.

Primary Use Cases

Printed circuit boards (PCBs) are key to modern electronics. They are found in almost every device you use daily. Their flexibility and dependability make them essential in many industries. Let’s look at some common ways PCBs are used.

Consumer Electronics

PCBs are the heart of gadgets like phones, laptops, and tablets. They link and hold the parts that make these devices work. Without PCBs, your favorite tech wouldn’t run. Even home appliances like microwaves and washing machines need PCBs to work well.Automotive Industry

Today’s cars are more than just engines and wheels. They have advanced systems for safety, navigation, and entertainment. PCBs control things like GPS, airbags, and parking sensors. They also manage engines and batteries in electric cars.Medical Devices

In healthcare, accuracy and trust are very important. PCBs are used in devices like heart monitors, MRI machines, and insulin pumps. Flexible PCBs are great for wearable medical devices since they can bend to fit the body.Aerospace and Defense

Aerospace and defense need strong PCBs for tough conditions. PCBs are used in airplane communication systems, radar, and missile controls. Their strength ensures they work well in extreme environments.Industrial Equipment

Factories use PCBs in machines and control systems. They help with automation, performance checks, and safety. For example, robotic arms and conveyor belts rely on PCBs to function.Telecommunications

The telecom industry depends on PCBs for devices like routers and modems. These boards allow fast and steady data transfer, keeping people connected.

Tip: When creating a PCB产品, think about the needs of the industry. For example, medical PCBs must meet strict safety rules, while car PCBs must handle heat and shaking.

PCBs are everywhere, from your phone to your car. Knowing their uses helps you see how they shape today’s world.

What is a PCBA?

Definition of PCBA

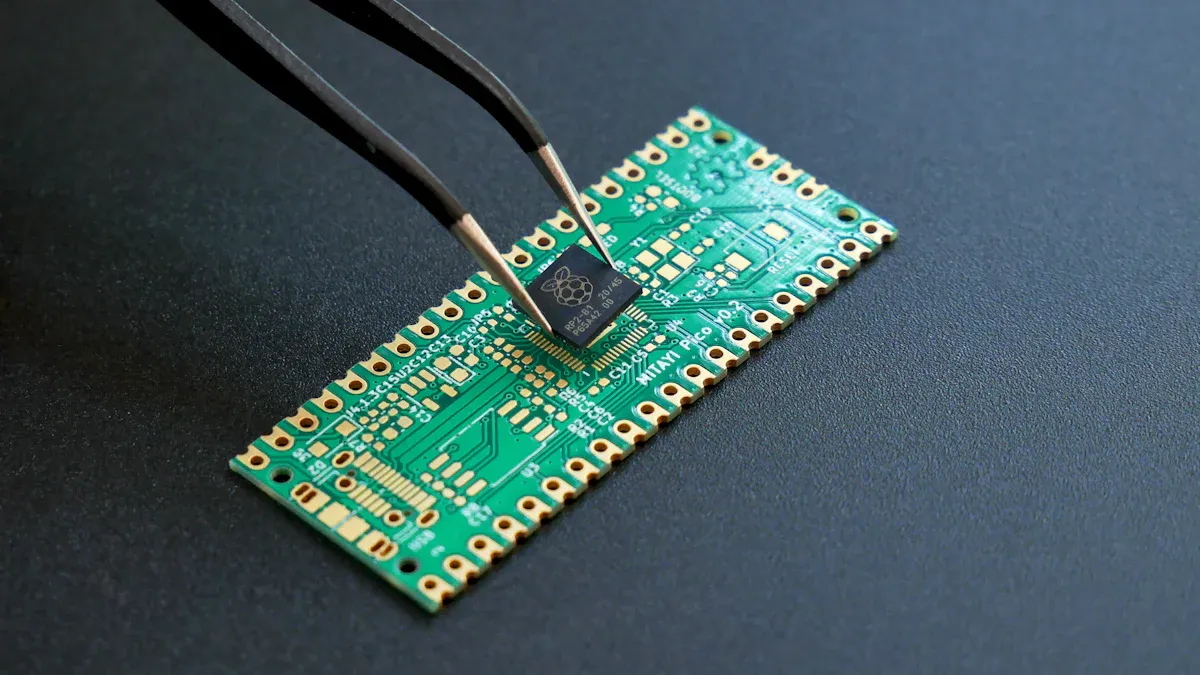

A PCBA产品, or printed circuit board assembly, is what makes a PCB产品 useful. It adds parts like resistors, capacitors, and microchips to the board. These parts turn the PCB产品 into something that can do specific jobs. Without a PCBA产品, a PCB产品 is just a blank board with no real purpose.

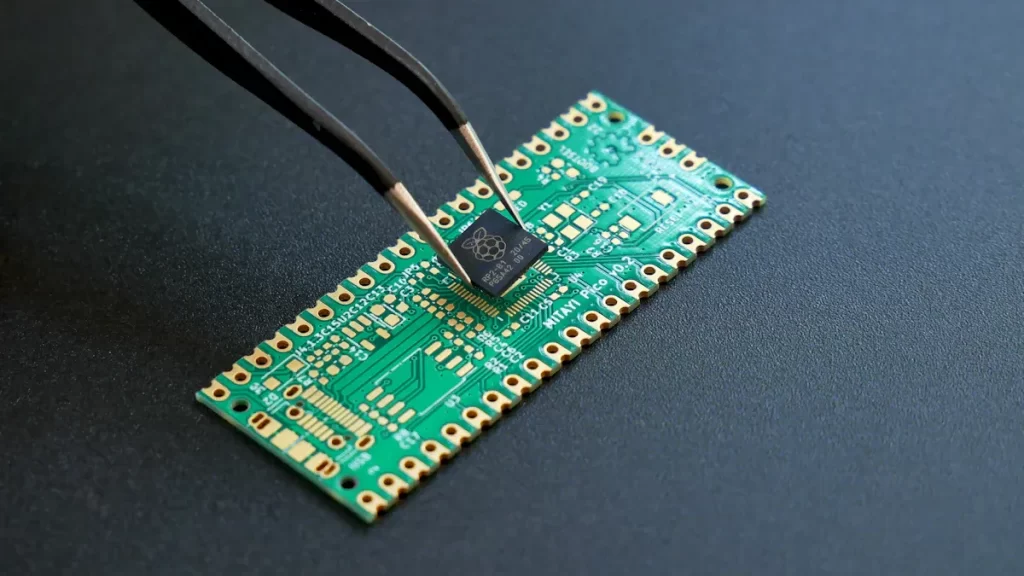

Assembly Process

Making a PCBA产品 needs careful work and accuracy. First, parts are placed on the PCB产品. This can be done by hand or with machines. Surface Mount Technology (SMT) puts parts directly on the board’s surface. Another way, Through-Hole Technology (THT), uses holes to hold parts, making them stronger.

Next, soldering attaches the parts firmly to the board. Machines like reflow soldering make this step fast and exact. After soldering, the PCBA产品 is tested to check if it works. Testing ensures the board meets quality rules and does its job well.

Importance in Electronics Manufacturing

PCBAs are key to making electronics work. They give PCBs the ability to perform tasks. Using machines for PCBA产品 assembly has changed how electronics are made. It saves time, cuts costs, and improves accuracy. Robots help make changes quickly and reduce mistakes. This leads to better products that last longer.

Improvement Type | Description |

|---|---|

Cost Efficiency | Saves money over time by using fewer workers and faster methods. |

Flexibility | Robots can be reprogrammed easily for new designs or products. |

Increased Efficiency | Faster production with machines means more products in less time. |

Enhanced Precision | Better tools make fewer mistakes, so products are more reliable. |

Cost Reduction | Smarter processes lower costs, making devices cheaper for buyers. |

PCBAs are vital for gadgets like phones, medical tools, and car systems. They make sure these devices work well and safely. Learning how PCBAs are made helps you understand the effort behind your favorite tech.

Key Differences Between PCB and PCBA

Construction Differences

A PCB产品 is a flat board made of fiberglass or resin. It has copper lines that let electricity flow. By itself, a PCB产品 doesn’t do anything. It’s just the base for building circuits.

A PCBA产品 is a finished PCB产品 with parts like resistors and chips. These parts are attached using methods like SMT or THT. They make the PCB产品 work and perform tasks.

Here’s a simple comparison:

Aspect | PCB Cost/Time | PCBA Cost/Time |

|---|---|---|

Cost | Lower | Higher |

Production Time | 1 to 3 weeks | 4 to 6 weeks |

Complexity | Less | More |

For example, making a PCB产品 might cost $5. Adding parts and assembly raises the cost to $30. This shows how much more effort goes into a PCBA产品.

Functional Differences

A PCB产品 is like a blank canvas. It connects parts but doesn’t do anything alone. It’s the skeleton of an electronic device.

A PCBA产品 is the brain of the device. With parts added, it can process data and manage power. For example, in a phone, the PCBA产品 helps it work and communicate.

Without a PCBA产品, devices wouldn’t function. Turning a PCB产品 into a PCBA产品 makes technology possible.

Role in Production

The PCB产品 is the first step in production. It’s made to fit the needs of the device. This includes designing, adding copper lines, and protective layers.

The PCBA产品 comes next. Parts are placed on the PCB产品 by machines or workers. Soldering connects the parts securely. Then, testing ensures the PCBA产品 works properly.

Making a PCB产品 takes about one week. A PCBA产品 takes longer, around four to six weeks. This extra time is important for big projects.

Tip: Plan for the extra time and cost of PCBA产品 production. This helps avoid delays and keeps your budget on track.

Knowing the differences between PCB产品 and PCBA产品 helps you design and build better devices. Whether simple or complex, understanding their roles is key.

Cost and Manufacturing Considerations

Cost Factors for PCB

The cost of making a PCB产品 depends on many things. Choosing the right maker is very important. Picking the cheapest option might seem smart, but it can cause problems. Badly made PCBs may fail, need fixes, or delay your project. For instance, a poorly made PCB产品 might need redesigning, costing more time and money.

The type of PCB产品 also affects the price. Simple single-layer PCBs are less expensive to make. But as the design gets more complex, the cost goes up. Multilayer PCBs, used in advanced gadgets, need more materials and detailed work. This makes balancing cost and quality very important in PCB产品 production.

Cost Factors for PCBA

Making a PCBA产品 costs more than making a PCB产品. The number of parts, board size, and layers all affect the price. Boards with many parts need special assembly methods, which cost more. Multilayer boards also take more effort and care to assemble.

The parts you choose can raise costs too. Rare or special parts are harder to find and cost more. Assembly costs can even be higher than making the PCB产品, especially for complex boards. Careful planning is key to managing PCBA产品 costs and staying within budget.

Manufacturing Challenges

Making PCBs and PCBAs has its own difficulties. Prototypes can be made fast, often in 1-2 days. This helps you test and fix designs quickly. But making large amounts takes longer, usually 4-6 weeks. Tight deadlines for big orders can make work harder and lower quality.

Good planning helps solve these problems. Working with manufacturers early can reduce delays and keep production smooth. Fixing issues before they happen ensures your product is made on time and meets quality standards.

Tip: Always plan for production time and challenges. This helps your product launch without delays.

Lead Time and Mass Production

Lead time and mass production are important in making electronics. Knowing these ideas helps you plan well and avoid delays.

What Is Lead Time?

Lead time means the total time to make a product. This starts from design and ends with delivery. For PCBs and PCBAs, it includes designing, testing, and manufacturing. Shorter lead times are better but depend on things like design difficulty, materials, and how many are made.

Tip: Share your design details early with manufacturers. This avoids errors and speeds up production.

Challenges in Mass Production

Mass production means making many PCBAs at once. It lowers costs but has some problems:

Quality Control: Checking every unit is hard.

Supply Chain Issues: Delays in getting parts slow work.

Scaling Up: Making more products needs good planning.

Ways to Improve Lead Time and Mass Production

Here’s how to make things smoother:

Pick Trusted Makers: Work with companies that deliver on time and do good work.

Use Machines: Automation makes assembly faster and reduces mistakes.

Plan Early: Order parts ahead to avoid running out.

Factor | Effect on Lead Time | Effect on Mass Production |

|---|---|---|

Design Difficulty | Makes it longer | Slows it down |

Part Availability | Makes it shorter | Speeds it up |

Automation | Makes it shorter | Improves it |

Note: Balancing lead time and mass production helps your product launch on time without losing quality.

Learning about these helps you make better choices and improve your process.

Applications and Industry Usage

Applications of PCBs

PCBs are important in today’s technology. They are found in almost every electronic device you use daily. Their ability to adapt makes them useful in many fields. For example, in healthcare, PCBs are used in heart monitors and testing machines. As technology improves, smaller and more dependable PCBs are needed, especially for wearable health devices and imaging tools.

The car industry also depends on PCBs. They power systems like sensors, driver-assistance tools, and electric car batteries. With the car market growing by 5% yearly from 2023 to 2028, advanced PCB designs are in high demand. Similarly, gadgets like smartphones and smart home devices need PCBs to work. These examples show how PCBs are essential in many industries.

Applications of PCBAs

PCBAs turn PCBs into working parts of electronic devices. They are crucial in fields where accuracy and dependability are a must. For example, in aerospace, PCBAs are used in power systems, communication tools, and monitoring devices. In cars, they help run navigation systems, entertainment units, and control tools.

PCBAs are also vital for safety and security. Devices like smoke alarms, motion detectors, and electronic locks rely on PCBAs to work properly. Their ability to combine complex parts makes them key to building advanced and reliable technology.

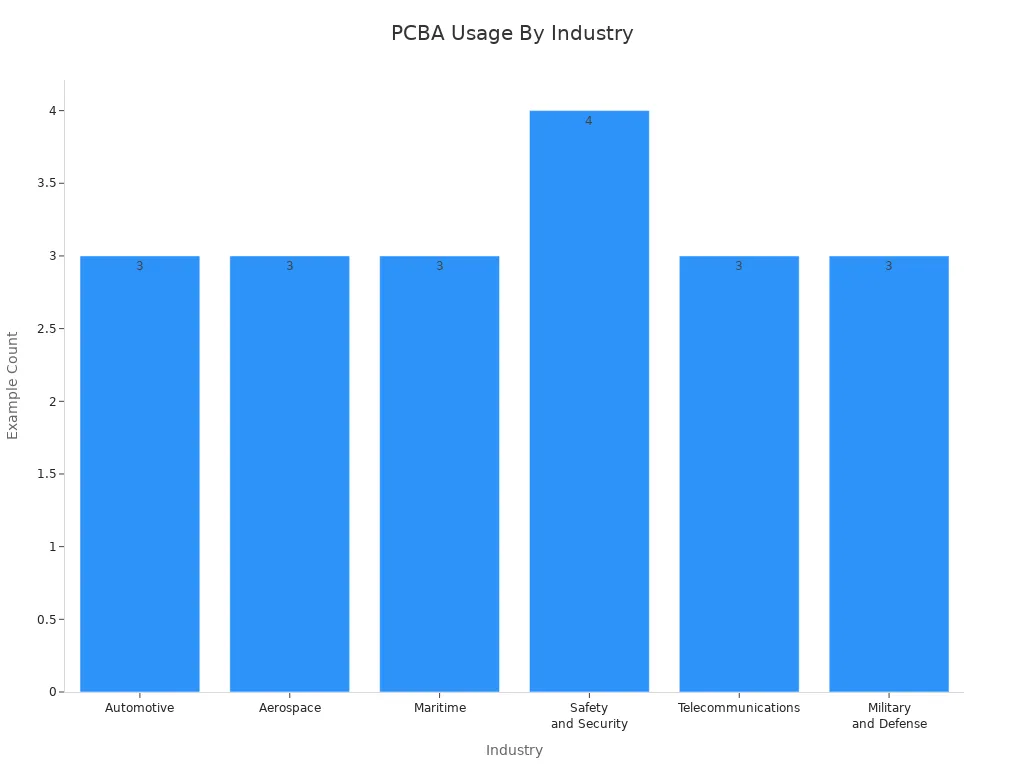

Industry-Specific Examples

PCBAs and PCBs are used in many industries. The table below shows some specific examples:

Industry | Examples of PCB Applications |

|---|---|

Automotive | – Navigation and entertainment systems |

Aerospace | – Power systems for planes |

Maritime | – GPS and radar systems |

Safety and Security | – Security cameras |

Telecommunications | – Telecom towers |

Military and Defense | – Communication tools |

These examples show how PCBs and PCBAs are used to create smart solutions in many industries.

Knowing the difference between PCB and PCBA helps in electronics. A PCB is just a plain board, while a PCBA has parts added to make it work. The table below shows their main differences:

Aspect | PCB产品 | PCBA产品 |

|---|---|---|

What It Is | Empty board | Board with attached parts |

Cost | Less expensive | Costs more because of assembly |

Use | Base for circuits | Works in electronic devices |

When planning, think about how PCB and PCBA affect cost, difficulty, and use. This helps you design better and produce successfully.

FAQ

What is the main difference between a PCB and a PCBA?

A PCB产品 is a plain board used in electronics. A PCBA产品 is a PCB产品 with parts like chips and resistors added, making it work.

Can you reuse a PCB after removing components?

Yes, a PCB产品 can be reused if it’s not damaged. Be careful when removing parts to avoid harming the copper lines or solder spots.

How do you choose between SMT and THT for assembly?

Pick Surface Mount Technology (SMT) for small designs and fast production. Use Through-Hole Technology (THT) for stronger builds in devices that face stress, like cars or factory machines.

Tip: Think about your device’s size, strength needs, and how many you’ll make.

Why are multilayer PCBs more expensive?

Multilayer PCBs need special methods and extra materials to make. Each layer adds difficulty, which raises the cost and time to produce. They’re best for small gadgets like phones and laptops.

How can you reduce PCBA production costs?

Lower costs by improving your design, using common parts, and working with skilled makers. Start planning early with your supplier to avoid mistakes and save time.

Note: Stick to standard parts to keep costs low.

See Also

Understanding The Distinctions Between Prototype And Production PCBs

Essential Technologies Shaping PCBA Production In Today’s Electronics

Achieving Superior Quality Through Expert PCBA Manufacturing Methods

Guidelines For Assembling PCBA While Avoiding Typical Mistakes

Evaluating Top Comprehensive PCBA Manufacturing Solutions For 2025