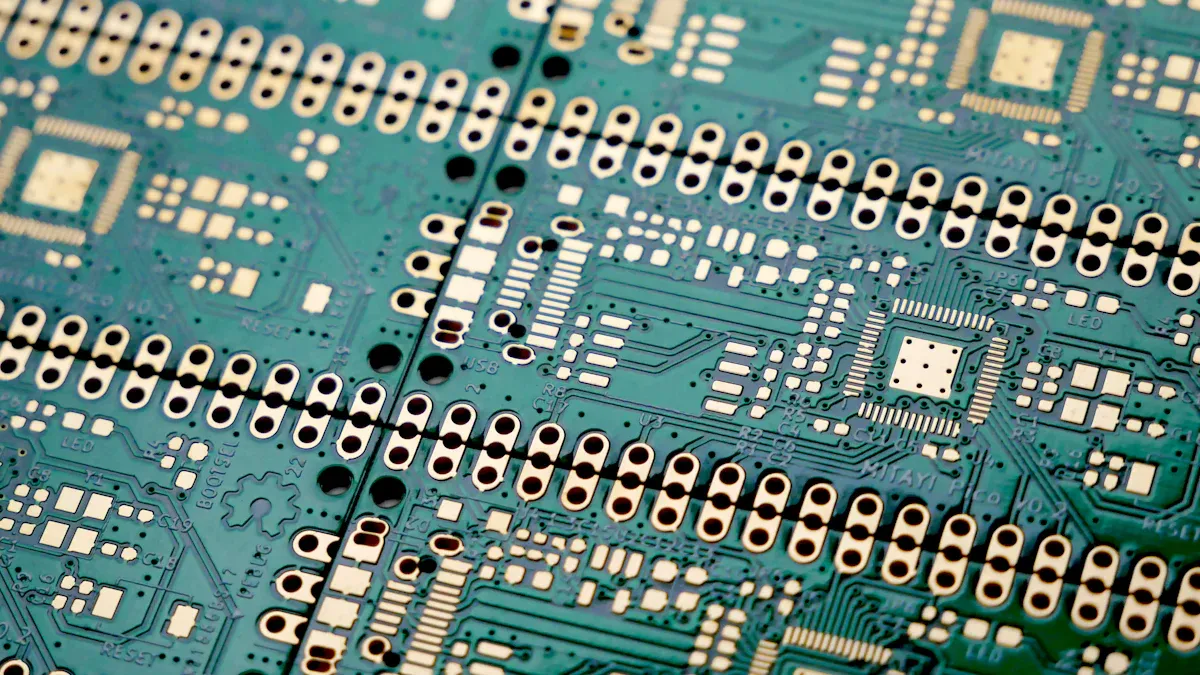

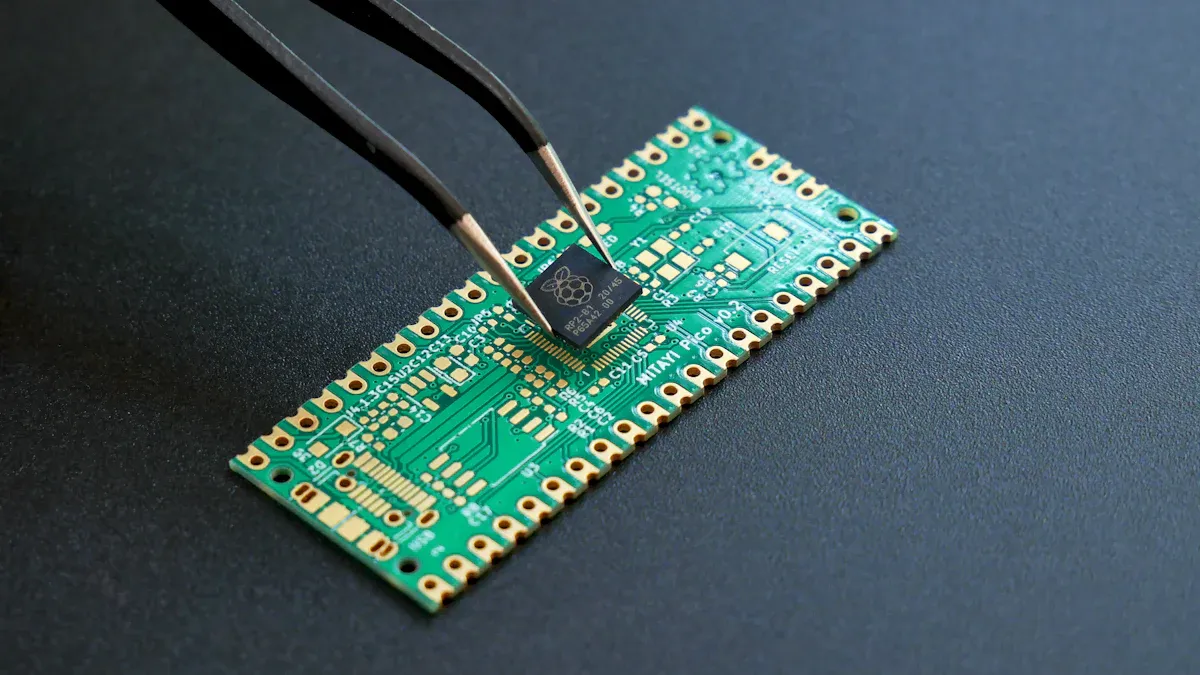

Today, factories require tools that operate without interruption. The резонит эффективно ensures smooth PCBA integration with machines, keeping operations running seamlessly. As industries adopt new technologies, they demand more advanced and reliable tools. PCBA technology supports this by enhancing speed and simplifying tasks. It integrates effectively with existing systems, helping companies maintain a competitive edge.

Key Takeaways

Smooth PCBA integration helps factories work without stopping, boosting output.

Modular PCBA designs make upgrades and fixes simple, fitting future needs.

Standard communication rules help new PCBA parts work with old systems, making them dependable.

Better testing improves product quality, cutting down on errors and ensuring systems work in all conditions.

Picking a trusted PCBA provider is key for success, giving good products and expert help.

Overcoming Automation Challenges

Making Old Systems Work with New Technology

Connecting new PCBA tech to old systems can feel hard. But, you can solve this by using reverse engineering. For example:

Old factory machines can work better with updated controls and new tech.

In transport, old vehicles can get modern features like better connectivity to match today’s communication systems.

Also, updating software for new parts may need changes in firmware or drivers. Careful testing makes sure these updates are safe and work well. Fixing these issues helps old systems last longer while using advanced PCBA tools.

Reducing Downtime During Setup

Stopping systems during setup can cause problems and cost money. PCBA setup avoids this by syncing data in real-time with PLM and ECAD tools. This syncing lowers design mistakes and helps teams work together. When everyone uses the newest design files, delays and downtime drop a lot.

Plus, sending correct data straight to factory software speeds up work and production. This keeps your systems running smoothly during setup.

Growing and Adapting with Ease

Modern factories need tools that grow with their needs. PCBA tech has modular designs that make fixing and upgrading simple. These designs help systems grow without needing big changes.

New Industry 4.0 tech adds flexibility by letting you watch and improve data in real-time. This boosts production and keeps systems ready for change. Using PCBA tools helps you build systems that fit your future plans.

Features of PCBA That резонит эффективно

Standardized Communication Protocols

Standardized communication protocols help PCBA work with automation systems. These protocols let devices “talk” easily, sharing data without issues. Following industry standards like IPC-2221 for PCB design and IPC-A-610 for assembly ensures high performance and reliability.

Tip: IPC standards build trust and keep manufacturing quality consistent.

Meeting ISO certifications and RoHS rules shows a focus on quality and the environment. These standards make PCBA solutions резонит эффективно by meeting global reliability benchmarks.

Modular and Customizable Designs

Modular designs let you adjust systems for changing needs. With modular PC setups, you can fix or upgrade parts without replacing everything. This reduces waste and helps protect the environment.

Custom PCBA designs make building devices like POS systems and cameras easier. They save time and improve efficiency, helping you stay competitive. Supporting repairs with replaceable parts makes maintenance simple and extends equipment life.

Did you know? Modular designs make repairs easier and prepare systems for future tech.

Advanced Testing and Quality Assurance

Advanced testing checks PCBA reliability and performance. Tests include design reviews, quality checks, and final inspections. For example, automated optical inspection (AOI) finds surface defects quickly, while X-ray tests spot hidden solder problems.

Quality Check | What It Does |

|---|---|

Design Review | Finds design problems before production starts. |

In-process Quality Control | Watches for defects during manufacturing. |

Automated Optical Inspection (AOI) | Quickly checks for surface flaws. |

X-ray Inspection | Finds hidden solder joint issues. |

Final Quality Check | Makes sure products meet all requirements before shipping. |

These tests ensure PCBA works well in different conditions. Focusing on quality at every step boosts production success and lowers defect risks. This makes systems efficient and dependable.

Benefits of Seamless Integration

Faster Deployment and Reduced Downtime

Seamless PCBA产品 integration helps set up systems quickly. It also reduces downtime during upgrades or changes. Using standardized protocols and modular designs makes connecting new parts easy. This keeps production lines running without stopping operations.

Real-time data sharing between PCBA产品 tools and factory software prevents delays. For example, updated design files shared instantly reduce mistakes. Teams stay on schedule, and production runs smoothly. This process saves time and keeps output steady.

Tip: Quick setups let you meet market needs faster and stay competitive.

Enhanced Efficiency and Productivity

Adding PCBA产品 technology to automation systems improves efficiency. Lean manufacturing methods cut waste and make workflows better. This leads to faster production and higher output without losing quality. For instance, a factory in Malta added new machines to save time and labor costs. This change boosted productivity noticeably.

PCBA产品 tools also improve product reliability by reducing reworks. Better quality ensures systems work well, helping you grow your operations. Using these technologies makes reaching production goals easier and more efficient.

Cost Savings and Optimized Processes

Seamless PCBA产品 integration lowers costs by improving processes. Instead of focusing only on cutting expenses, use Total Cost of Ownership (TCO) models. These models help you see all costs and align spending with company goals.

Here are ways to save money with PCBA产品 integration:

Place parts where machines can reach them easily to lower handling costs.

Simplify assembly steps to avoid expensive designs.

Add test points to make testing faster and cheaper.

Use fewer parts to reduce handling and testing costs.

Choose multi-function parts to do several tasks, cutting the need for extras.

These strategies make production more efficient and save money over time. Modular designs also keep systems flexible for future updates, making investments last longer.

Real-World Applications

Robotics and Assembly Line Integration

PCBA helps robots work better in factories and other places. It lets robots do hard tasks with accuracy and dependability. For example:

Industrial robots use PCBAs to control circuits and manage movements.

Service robots depend on PCBAs for multitasking and talking to devices.

Medical robots need PCBAs for precise surgeries and steady power use.

Type of Robot | How PCBA Helps |

|---|---|

Industrial Robots | Controls circuits, manages movements, and connects sensors. |

Service Robots | Handles multitasking, device communication, and navigation decisions. |

Medical Robots | Provides precise surgery control and stable power management. |

Using PCBA makes robots more reliable and efficient, even in tough jobs.

IoT-Enabled System Enhancements

PCBA is key for IoT systems, making them connect and save energy. It uses sensors to collect and send data accurately. Wireless tools like Wi-Fi and Bluetooth help devices talk to each other. For instance, PCBAs process sensor data fast, helping devices work smartly. They also save power, making batteries last longer.

Benefits of PCBA in IoT systems include:

Easy connection between devices.

Better security for protecting data.

Custom designs for special IoT needs.

PCBA also supports smaller designs, perfect for tiny devices like wearables. Using PCBA makes IoT systems smarter and more useful.

Electronics Manufacturing Success Stories

One factory used PCBA to improve a tricky circuit design. This made production faster and reduced mistakes during testing. Advanced tests helped create more good products. Feedback and design changes made the final product even better.

This shows how PCBA can improve manufacturing, giving high-quality results. By using PCBA, you can make your processes better and meet industry rules easily.

Steps for Smooth Integration

System Compatibility Assessment

Before adding PCBA产品 to your systems, check compatibility first. This step makes sure all parts work well together. Use tools and tests to see if your system is ready.

Power Testing: Check if power circuits stay stable when turning on or off.

Function Testing: Test if parts work correctly in real-life situations.

Communication Testing: Make sure data moves smoothly using protocols like UART or Ethernet.

Performance Testing: Test signals and timing to keep systems running their best.

Environment Testing: See how systems handle heat, cold, and moisture.

Software Testing: Confirm that software and firmware work properly after installation.

These checks find problems early, saving time and effort later. Using methods like Kepner-Tregoe helps you study issues carefully. This avoids mistakes and makes integration easier.

Partnering with Reliable PCBA Providers

Picking the right PCBA产品 provider is very important. Good providers offer expert help and high-quality products. Look for these things when choosing a partner:

Certifications: Make sure they follow rules like ISO9001 or UL standards.

Material Control: Check if they use precise materials and careful manufacturing.

Experience: Look at past projects to see their success and delivery speed.

A trusted provider gives great products and helps during setup. This teamwork lowers risks and ensures everything works well for a long time.

Implementing Phased Integration Strategies

Using small steps for integration lowers risks and makes changes easier. Start with the most important systems and data. Move them slowly to avoid overwhelming your team.

This plan reduces problems and lets you fix issues one at a time. For example, moving data in small parts keeps the process simple. Teams can focus better without feeling stressed.

Breaking the process into smaller steps helps track progress and make changes as needed. This way, downtime is less, and the team feels confident about the changes.

Tip: Small steps keep your systems steady while adding new tools.

Smooth PCBA integration is key for today’s automation systems. It keeps your work running well and ready for future needs. The advantages are easy to see: better productivity, flexible solutions, and lower costs.

Advantage | What It Means |

|---|---|

Lower Costs | Making more products reduces costs and improves efficiency. |

Better Teamwork | Dividing tasks into steps makes work faster and improves quality. |

New Technology | Using advanced tools makes products better and production quicker. |

Smarter Resource Use | Managing materials wisely saves money and boosts efficiency. |

Picking custom PCBA options helps you gain these benefits and stay competitive in the market.

FAQ

What is PCBA, and why does it matter in automation?

PCBA means Printed Circuit Board Assembly. It links electronic parts to a board, helping devices work. In automation, PCBA helps systems talk to each other. This makes them more reliable and efficient.

How does PCBA integration prevent downtime?

PCBA uses real-time data sharing and standard rules. These features cut mistakes during setup or updates. It ensures systems fit together and start quickly, keeping them running smoothly.

Can PCBA work with older systems?

Yes, PCBA works with old systems too. Reverse engineering and modular designs make them compatible. Testing ensures they work well, giving old machines new features and a longer life.

Which industries gain the most from PCBA?

Industries like factories, healthcare, and IoT benefit a lot. PCBA improves robots, medical tools, and smart devices. It boosts accuracy, connections, and saves energy, making it vital for modern use.

How do I pick the best PCBA provider?

Choose providers with certifications like ISO9001. Check their skills and material quality. Good providers give expert help, ensuring smooth setups and long-lasting system performance.

Tip: Working with a trusted provider lowers risks and ensures great results.

See Also

The Impact of PCBA on Today’s Industrial Automation Systems

PCBA’s Role in Boosting Industrial Automation Efficiency

Exploring PCBA’s Importance in Industrial Automation