The need for Low Volume IIoT PCB Assembly is growing fast. Many industries now use smart manufacturing to improve their work. About 89% of companies are spending money on IIoT and digital factories. This shows how important it is to pick a good manufacturer. A reliable partner in Low Volume IIoT PCB Assembly provides you with quality circuit boards, quick delivery, and saves money.

IIoT technology is changing how industries work. Today, half of all new machines sold have IIoT features. This makes it important to find a manufacturer with advanced skills in Low Volume IIoT PCB Assembly. Whether you’re a new business or growing bigger, the right manufacturer helps you succeed.

Key Takeaways

Pick a manufacturer with good technical skills. Modern tools and trained workers make better PCBs with fewer mistakes.

Quick delivery and flexibility are important for small orders. Find manufacturers who can handle design changes fast and send prototypes quickly.

Choose manufacturers with strong quality checks. Good testing like AOI and ICT finds problems early, making products more reliable.

Think about cost when picking a manufacturer. Experts in small orders can save money on setup and storage while keeping quality high.

Good customer support and clear communication make things easier. Helpful support matches your needs with their skills, avoiding errors.

Key Criteria for Choosing a Manufacturer

Technical Capabilities

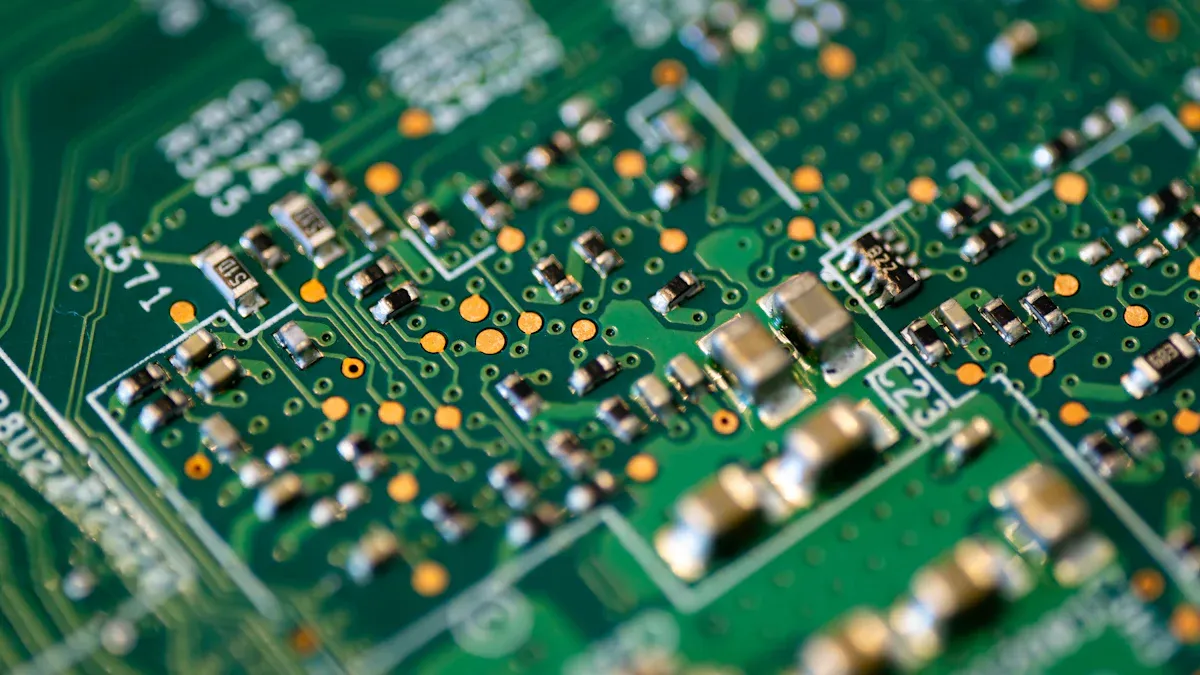

Pick a manufacturer with strong technical skills. Advanced tools help make better PCBs. Using good materials improves how long products last. This lowers the chance of problems and saves money.

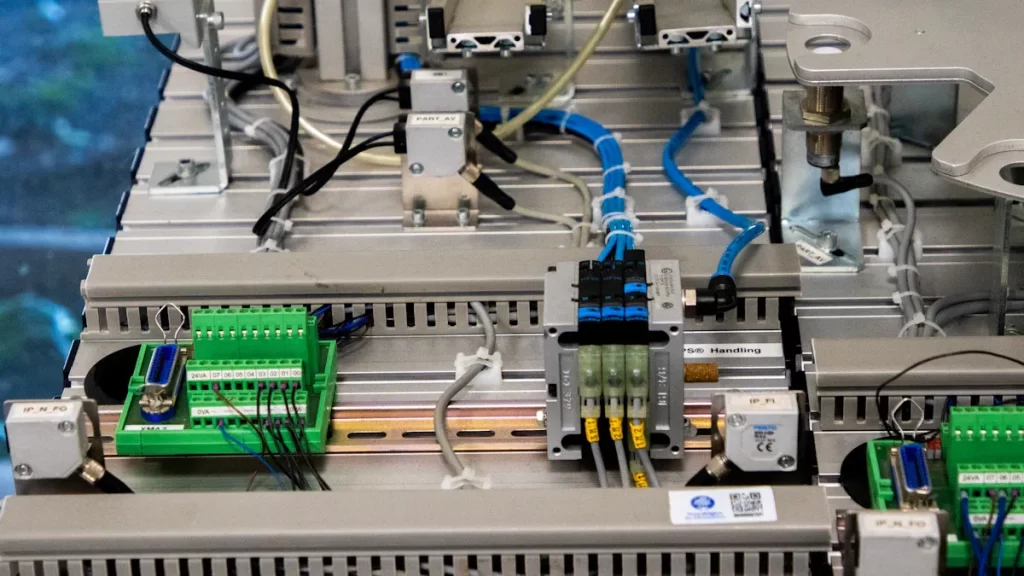

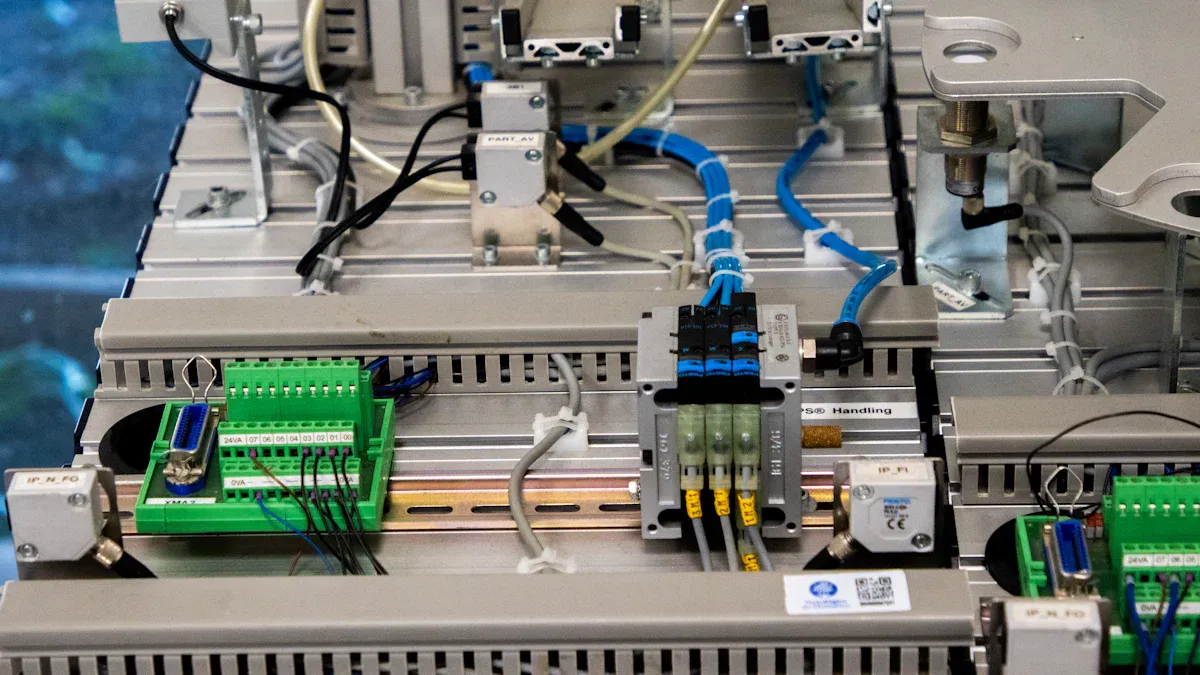

Modern factories use smart tools like AOI and X-ray checks. These find hidden mistakes and ensure PCBs meet rules. ICT and functional tests confirm boards work properly. Additive manufacturing creates unique designs faster. It removes old design limits and speeds up production.

Skilled workers are also important. Experts focus on details to improve PCB quality. Choosing a skilled manufacturer ensures your products fit IIoT needs.

Lead Times and Flexibility

Fast delivery is key for small production runs. Low-volume PCB makers often finish prototypes quicker than big factories. They also allow easy design changes during development.

Here’s a table comparing prototyping and mass production:

Aspect | Prototyping | Mass Production |

|---|---|---|

Lead Time | Fast delivery | Slower delivery |

Flexibility | Easy design changes | Fixed designs |

Assembly Techniques | Manual methods | Automated methods |

Equipment | Basic tools | Specialized machines |

Cost per Unit | Higher costs | Lower costs |

Design Iterations | Many changes allowed | Finalized designs |

Volume | Small batches (1-100 units) | Large batches (thousands or more) |

This table helps you pick the right manufacturer for your project.

Quality Control Standards

Good quality checks are vital for electronics. Factories use AOI to spot connection or part issues. ICT finds problems in circuits and parts. These tests keep standards high.

Other tests like TDR and Flying Probe improve quality. DFM and DFA checks catch problems early. These steps ensure PCBs are error-free and ready to use.

Choose a factory with strong quality checks to avoid defects. This improves how reliable your products are.

Cost-Effectiveness for Low-Volume Production

Saving money is important for low-volume IIoT PCB assembly. Manufacturers who focus on small batches work to cut costs. They do this while keeping the quality high. You save on storage, setup, and avoid big financial risks. This makes small projects easier and less stressful.

Here’s how they keep costs low:

Factor | Description |

|---|---|

Flexibility | Lets you customize products without spending too much money. |

Reduced Inventory Costs | Makes smaller batches, so you don’t pay for extra storage. |

Lower Setup and Tooling Costs | Needs fewer tools, so you spend less at the start. |

Reduced Risk | Matches production to demand, so you don’t lose money on extras. |

Picking a manufacturer skilled in small-batch production helps you focus on new ideas. Many companies also offer turn-key PCB services. This makes the process faster and easier. It also helps you get your product to market quickly.

Customer Support and Communication

Good customer support and clear communication are very important. They make PCB assembly and production much smoother. When manufacturers focus on these, you get better results. Clear communication helps them understand your needs. This reduces mistakes and speeds up the process.

Here are ten ways good support helps you:

Makes sure you and the manufacturer understand each other.

Matches designs to your needs, improving quality.

Helps you make smart choices and save money.

Speeds up projects by getting details quickly.

Solves problems when things don’t go as planned.

Improves designs to make production easier.

Builds reliable products through teamwork.

Sets clear goals, so you’re happy with the results.

Prepares you for risks, avoiding surprises.

Encourages new ideas by listening to your input.

Manufacturers with strong customer support make things easier for you. Their knowledge helps you handle tricky steps. By working with a helpful provider, you can finish your small projects with great results and less trouble.

Detailed Manufacturer Comparisons

Hemeixin PCB & Assembly

Product Details

Hemeixin PCB & Assembly focuses on fast printed circuit assembly services. They make single-sided, double-sided, and multilayer PCBs for low volume IIoT PCB assembly. They also offer advanced prototyping to test designs before mass production.

Technical Parameters

Hemeixin delivers top-quality prototypes with precise measurements. They use tools like AOI and X-ray to avoid defects. Their work follows IPC-A-610 standards, ensuring dependable products.

Metric | Description |

|---|---|

Overall Equipment Effectiveness (OEE) | High OEE means machines work efficiently, reducing delays. |

First-Pass Yield | High first-pass yield cuts down on rework, saving time. |

Cycle Time | Short cycle times allow faster delivery of small orders. |

Application Scenarios

Hemeixin’s services are great for industries needing quick prototypes and small batches. These include industrial automation, smart sensors, and IIoT devices. Their speed makes them perfect for fast-moving markets.

Pros and Cons

Pros:

Fast delivery for prototypes.

High-quality standards with advanced testing tools.

Flexible options for small-batch production.

Cons:

Costs are higher than mass-production manufacturers.

Not ideal for large-scale orders.

Tip: Need quick prototypes for IIoT designs? Hemeixin is a smart pick. Their focus on speed and quality lowers risks during development.

PCBWay

Product Details

PCBWay is a flexible ems pcb assembly provider known for being affordable and reliable. They offer PCB manufacturing, SMT assembly, and prototyping. Free upgrades in multilayer PCB materials improve durability, making them great for IIoT projects.

Technical Parameters

PCBWay uses advanced methods while keeping costs low. Their multilayer PCBs handle complex designs, and their SMT assembly places parts accurately.

Metric | Description |

|---|---|

Scrap Rate | Low scrap rates reduce waste and improve efficiency. |

First-Pass Yield | High first-pass yield ensures fewer errors and rework. |

Cycle Time | Competitive cycle times help finish projects faster. |

Application Scenarios

PCBWay is ideal for startups, hobbyists, and small businesses. Their low prices and good quality suit IIoT devices like smart meters, sensors, and wearables.

Pros and Cons

Pros:

Budget-friendly for small orders.

Reliable quality for IIoT projects.

Offers many services, like prototyping and assembly.

Cons:

Longer wait times for complex designs.

Fewer customization options for advanced needs.

Note: PCBWay’s low prices and good quality make it great for budget projects. Their services help bring IIoT ideas to life affordably.

JLCPCB

Product Details

JLCPCB is a top ems pcb assembly provider offering low-cost solutions for small orders. They provide PCB manufacturing, SMT assembly, and prototyping. Discounts for first orders make them popular with startups and hobbyists.

Technical Parameters

JLCPCB focuses on basic PCBs with decent quality. Their SMT assembly places parts accurately, and their prototyping helps test designs quickly.

Aspect | Details |

|---|---|

Pricing Structure | Very low prices for small orders. |

Minimum Order Quantities | Small minimum orders, perfect for prototypes. |

Quality Standards | Good for most hobby and prototype projects. |

Service Offerings | Includes PCB manufacturing and assembly. |

Special Deals | Discounts for first-time orders and prototypes. |

Application Scenarios

JLCPCB is great for low-cost projects needing small batches. Their services are used in school projects, hobby designs, and IIoT prototypes like smart home devices and sensors.

Pros and Cons

Pros:

Very affordable for small orders.

Small minimum order sizes.

Frequent discounts and deals.

Cons:

Limited for complex designs.

Quality may not suit high-end needs.

Tip: On a tight budget? JLCPCB offers great value. Their low prices and small order sizes are perfect for prototypes and small IIoT projects.

Advanced Circuits (4PCB)

Product Details

Advanced Circuits (4PCB) is a trusted name in ems pcb assembly. They create PCBs for both prototypes and full production. Their products include single-layer, double-layer, and multilayer PCBs. They also handle complex designs, making them a flexible option for printed circuit assembly.

They are skilled at managing both small and large orders well. Their “FreeDFM” tool checks for design problems before production. This tool helps improve designs, saving time and avoiding mistakes.

Technical Parameters

Advanced Circuits (4PCB) uses modern tools to make top-quality PCBs. Their factories meet IPC Class 2 and Class 3 rules for strong and reliable boards. They also use advanced tests like Flying Probe and X-ray to ensure quality.

Metric | Description |

|---|---|

Layer Count | Can make up to 40 layers for tough designs. |

Minimum Trace Width | 0.005 inches, good for dense layouts. |

Turnaround Time | Same-day delivery available for prototypes. |

Application Scenarios

Advanced Circuits (4PCB) works well for industries needing dependable PCBs. These include aerospace, medical tools, and industrial machines. Their ability to handle tricky designs makes them great for low volume iiot pcb assembly.

Pros and Cons

Pros:

High-quality boards with advanced testing.

Fast delivery for prototypes.

Free tools to improve designs.

Cons:

Costs more for small orders.

Fewer options for special designs.

Tip: Need strong PCBs for important projects? Advanced Circuits (4PCB) delivers great quality and support. Their FreeDFM tool helps you save time and money.

Osh Park

Product Details

Osh Park is a favorite for ems pcb assembly, especially for small projects. They focus on small orders, starting with just three boards. This makes them affordable for early-stage projects. Their PCBs use strong materials for long-lasting performance.

Osh Park is also eco-friendly. They combine many orders on one panel to cut waste. This method saves money and helps the environment.

Technical Parameters

Osh Park ensures steady quality with advanced methods. Their boards meet IPC Class 2 standards, which work for most uses.

Metric | Description |

|---|---|

Minimum Order Quantity | Only 3 boards, great for small projects. |

Material | Uses FR4 with ENIG (gold finish) for strength. |

Turnaround Time | Standard delivery in 12 days; faster options available. |

Application Scenarios

Osh Park is ideal for hobbyists, startups, and small companies. Their services are used for IIoT prototypes, smart devices, and school projects. The low order size lowers costs, making it easy to test new ideas.

Pros and Cons

Pros:

Cheap for small orders.

Eco-friendly production process.

Strong materials and finishes.

Cons:

Slower delivery for standard orders.

Not suited for very complex designs.

Note: Osh Park is a budget-friendly choice for small projects. Their eco-friendly methods also support sustainable goals.

Comparison Table

Comparing Key Factors Side-by-Side

Here’s a table to compare top manufacturers for low-volume IIoT PCB assembly. It shows their strengths and weaknesses clearly.

Manufacturer | Technical Skills | Delivery Speed | Quality Checks | Cost-Friendly | Customer Help |

|---|---|---|---|---|---|

Hemeixin PCB & Assembly | Uses advanced tools and tests | Quick for prototypes | High standards, IPC-A-610 compliant | Costs more for small orders | Very responsive and detailed |

PCBWay | Reliable multilayer PCBs and SMT assembly | Good cycle times | Decent quality for budget projects | Affordable for small runs | Great for startups and hobbyists |

JLCPCB | Basic PCB features | Fast prototyping | Okay for simple designs | Very cheap | Limited support for custom needs |

Advanced Circuits (4PCB) | Handles tough designs with 40 layers | Same-day prototypes | Meets IPC Class 2 and 3 rules | Costs more for small batches | Offers tools to improve designs |

Osh Park | Eco-friendly with strong materials | Slower delivery | Steady quality for small projects | Cheap for small orders | Ideal for hobbyists and startups |

This table helps you pick the best manufacturer for your project.

Strengths and Weaknesses Overview

Each manufacturer has its own pros and cons. Knowing these helps you match them to your project.

Hemeixin PCB & Assembly: Great tools and fast delivery for prototypes. But, higher costs make it less ideal for tight budgets.

PCBWay: Affordable and good quality, perfect for startups. However, complex designs may take longer to finish.

JLCPCB: Cheapest option for small orders. Yet, it lacks advanced features for complex IIoT designs.

Advanced Circuits (4PCB): Excellent for complex designs and quick prototypes. But, higher costs may not suit smaller budgets.

Osh Park: Best for hobbyists and eco-friendly users. Slower delivery might not work for urgent needs.

To choose wisely, talk to your team and check customer reviews. A SWOT analysis can also help you find the best fit for your goals.

Tip: Match your project needs to industry standards to pick the right ems pcb assembly partner.

Picking the right ems pcb assembly partner is very important. Each company has special strengths for different needs. Hemeixin PCB & Assembly is great for fast, high-quality prototypes. It works well for industries needing accuracy and quick results. PCBWay offers good prices and advanced tools, making it a solid choice for startups. JLCPCB is the best option for saving money on small projects. Osh Park is eco-friendly and allows small orders, perfect for hobbyists and new startups.

When choosing a manufacturer, match their skills to your IIoT project. Studies show checking things like growth potential and system features helps. For instance, PCBWay’s ISO 9001/UL certifications and on-time delivery make them reliable for complex IIoT tasks. JLCPCB’s quick prototyping and low prices are great for testing ideas.

Tip: Think about what your project needs most. Whether it’s speed, cost, or advanced tools, the right partner will help you succeed in small-scale production.

FAQ

1. What is low-volume IIoT PCB assembly?

Low-volume IIoT PCB assembly makes small amounts of circuit boards. These boards are for industrial IoT devices. It’s great for testing and special uses because it’s flexible and saves money.

2. How do I pick the right manufacturer?

Look at their skills, delivery speed, and quality checks. Also, check their prices and customer help. Choose one that fits your needs, like fast prototypes or staying on budget.

3. Why does quality control matter in PCB assembly?

Quality control makes sure your boards work well. Tests like AOI and ICT find problems early. This lowers risks and makes your products better. Good quality protects your money and reputation.

4. Can low-volume production save money?

Yes, it can save money by lowering starting costs and storage fees. Small-batch makers often have fair prices and easy services. This makes the process simple and less risky.

5. Which manufacturer is good for hobbyists and startups?

Osh Park is great for hobbyists and new businesses. They have low prices, small order sizes, and eco-friendly methods. This makes them perfect for small projects and testing ideas.

See Also

Emerging Trends Influencing Industrial IoT PCB Assembly By 2025

Essential Practices for Low-Volume PCBA Production from 1 to 500

Crucial Technologies Advancing PCBA Manufacturing in Consumer Electronics

Cost-Effective Strategies for Optimizing Small Batch PCBA Production

Perfecting PCBA Manufacturing Methods for Superior Quality Outcomes