Metalwork mixes creativity and accuracy, making it fun to learn. With practice, you can turn raw materials into amazing items. A tidy workshop helps you work faster and better. Start by learning about tools like hammers, anvils, and welders. Practise simple techniques first before trying harder ones. Mistakes will happen, but they help you learn. Always stay safe by wearing safety gear and keeping your space clean. Metalwork is not just a skill; it is a craft that improves with effort.

Key Takeaways

Keep your workspace clean and organised with tools like hammers, anvils, and welders to work better.

Pick the right metal for your task; aluminium is easy for beginners, while steel works well for tough jobs.

Stay safe by wearing safety gear and keeping your workspace airy to avoid breathing bad fumes.

Learn simple skills like cutting and filing first. This helps you feel ready for harder designs.

Use online guides and groups to learn more and meet others who enjoy metalworking.

Setting Up Your Metalwork Workspace

Essential Tools for Metalworking

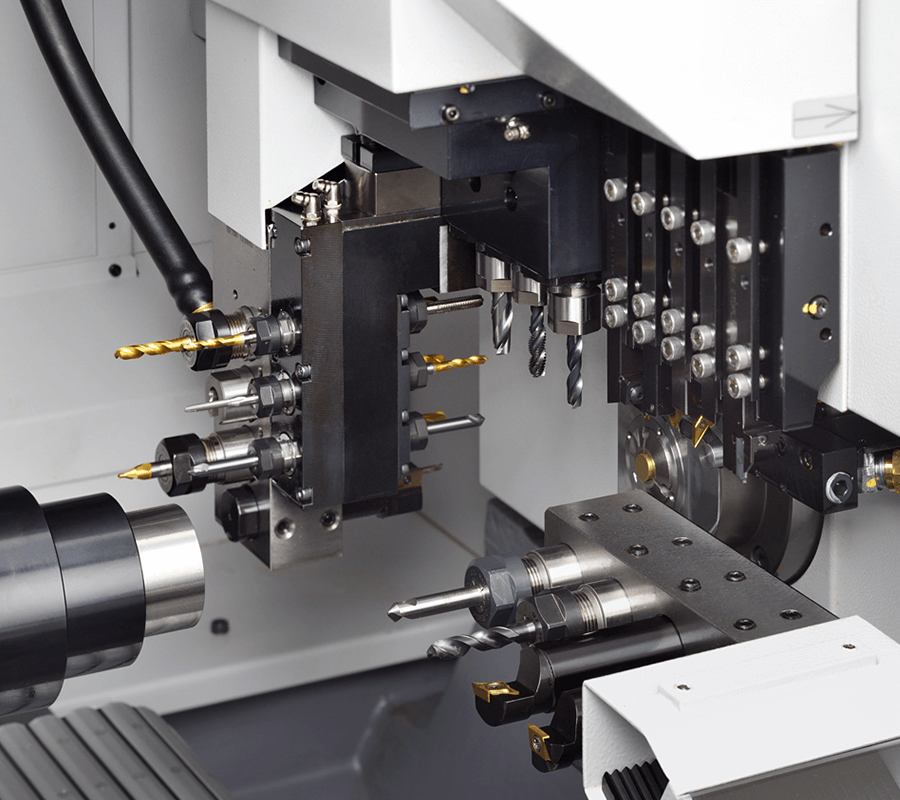

A good workshop setup is key for metalworking success. Start by collecting basic tools. You need a strong hammer and anvil to shape metal. Use files to smooth edges and a hacksaw for cutting. To join metal pieces, get a dependable welder. For detailed designs, advanced tools like a lathe or milling machine are helpful. These tools let you work with precision and detail. Keep your tools tidy and close by to save time.

Selecting the Right Materials

Picking the right metal is important for your project. Learn about different metals and their uses. Aluminium is light and easy to use, great for beginners. Steel is strong and can be used for many things. Copper and brass look nice, perfect for decorations. Match the metal to your project’s needs. For example, stainless steel is good for wet areas because it doesn’t rust. Using good materials makes your work last longer and look professional.

Ensuring Safety in Your Workspace

Safety is the most important thing in a metal workshop. Wear gloves, goggles, and a welding helmet to protect yourself. Make sure your workspace has good airflow to avoid breathing harmful fumes. Keep flammable items away from heat. Follow safety rules like those in NFPA 70E to lower risks. This guide focuses on training to prevent electrical dangers like shocks or flashes. The table below explains its main points:

Evidence Type | Description |

|---|---|

Safety Standard | NFPA 70E gives safety tips and stresses the need for training. |

Importance | It helps protect workers from electrical dangers like shocks and flashes. |

Industry Impact | Training ensures workers can handle risky tasks safely. |

Check your machines often to make sure they work well. A clean and neat workspace reduces accidents and helps you create great projects.

Tackling Challenges in Metalwork

Easy Techniques for Beginners

Starting metalwork can seem hard, but simple steps help. Practise basic tasks like cutting, filing, and shaping small metal pieces. These activities teach you how to use tools properly. Focus on making straight cuts and smooth edges first. Move to harder designs only after mastering the basics.

Experts suggest learning everything together—tools, materials, and safety. For example:

Catriona Gilbert says safety and tool knowledge are vital for beginners.

Watch beginner videos or use online guides to learn about machines.

Knowing the process well makes metalwork less scary.

Be patient. Learn each step slowly. Don’t rush into difficult techniques.

Avoiding Common Mistakes in Metalwork

Mistakes happen, but avoiding them saves time and effort. A common error is using the wrong metal for a project. Always pick materials that fit your design. For example, aluminium is good for light items, while steel suits heavy-duty work.

Another mistake is not taking care of tools. Blunt tools can ruin your work and cause accidents. Check and sharpen your tools often to keep them ready.

Wrong measurements also cause problems. Always double-check sizes before cutting or welding. A small mistake can spoil your work. Keep a ruler or tape measure nearby for accuracy.

Important Safety Tips for Metalworkers

Safety is the most important thing in metalwork. Wear gloves, goggles, and a welding helmet to stay safe from sparks and sharp edges. Make sure your workspace has good airflow to avoid breathing harmful fumes.

Keep your tools and area clean to avoid accidents. Store sharp tools safely and away from your work spot. Check your equipment often to ensure it works well. Broken tools can cause injuries.

Follow safety rules like NFPA 70E, which teaches how to handle electrical risks. This includes training to prevent shocks and flashes. Knowing safety rules helps you work confidently and stay safe.

By following these tips, you can work safely and improve your skills.

Advanced Metalworking and Welding Tips

Precision Techniques for Professional Craftsmanship

To work precisely, use steady hands and proper tools. Always measure twice before cutting to avoid mistakes. Tools like callipers or micrometres help with exact measurements. These tools ensure your work stays consistent. Before welding, check that pieces fit perfectly. Even a small gap can weaken the joint. Use clamps or jigs to hold metal firmly while you weld.

For detailed designs, advanced machines like CNC machines are helpful. These machines cut and shape metal automatically for perfect results. If you prefer manual work, practise with fine-toothed files or jeweller’s saws. These tools help you make detailed patterns and shapes. Patience and focus are important for professional-quality work.

Creative Approaches to Metalworking Projects

Metalwork allows you to be very creative. Try different methods to make unique items. For example, mix metals like copper and brass for a bold look. This works well for jewellery or wall decorations.

You can also reuse old metal objects creatively. Turn an old wrench into a coat hook or scrap metal into art. This saves materials and adds personality to your work. Experiment with texturing methods like hammering or embossing. These techniques make flat surfaces more interesting.

Adding welding to your designs gives even more options. Welded pieces can create strong and artistic structures. For example, weld a metal frame to make a custom table base. Use your imagination and try new ideas without fear.

Adding Finishing Touches for a Polished Look

Finishing makes your metalwork look amazing. Polishing is simple and effective. It smooths surfaces and makes them shiny, perfect for decorations or fixtures. Use a polishing wheel or soft cloth with metal polish for the best shine.

Chemical colouring is another way to improve your work. It creates bright colours or aged looks using chemical reactions. This not only makes your piece look better but also adds useful features. Heat colouring is another option. It adds beauty and helps identify parts used in high heat, like in aerospace.

Always clean your metal before finishing. Dirt or grease can ruin the final look. A well-finished piece looks professional and lasts longer, making your effort worth it.

Expanding Your Metalworking Knowledge

Online Resources and Tutorials

The internet is full of tools to grow your metalworking skills. Watch videos on YouTube to learn welding, cutting, and shaping. Many creators show steps clearly, making it simple to follow. Websites like Instructables and Metalworking Nation share project ideas and helpful tips.

If you want structured lessons, try online courses. Platforms like Udemy and Skillshare have classes for beginners and experts. These courses often include practice tasks and downloadable guides. Save useful blogs and forums to stay updated on new tools and machines.

Tip: Keep your favourite links in one folder for easy access.

Joining Metalworking Communities

Joining a group of metalworkers can teach you a lot. Look for local clubs or online groups where people share advice and stories. Facebook groups and Reddit’s r/metalworking are good places to connect.

Talking with others lets you ask questions and share your work. You can also learn from their mistakes and successes. Some groups organise challenges or team projects to improve your skills and creativity.

Note: Being active in these groups can help you make friends and find mentors.

Participating in Workshops and Events

Workshops and events give you hands-on practice with experts. Local craft centres or trade schools often run metalworking sessions. These let you try welding and other techniques with guidance.

Trade shows and exhibitions are also great for learning. They display the newest tools and machines, showing you industry trends. You can meet professionals and get fresh ideas for your projects.

Pro Tip: Take a notebook to write down tips and tricks you learn.

Metalworking is not only a craft but also a way to grow and be creative. Use the tips in this guide to get better at metalwork. Practise often and try out different methods to improve. Every project you finish will make you more confident and skilled.

Remember: The journey matters as much as the result. Face challenges, enjoy learning, and let your creativity show in every piece you create.

FAQ

What metal is easiest for beginners to use?

Aluminium is great for beginners. It is light and simple to shape. Cutting and welding it takes less effort. Practise basic skills with aluminium before trying harder metals like steel.

How should you clean metal before starting work?

Use sandpaper or a wire brush to get rid of rust. Wipe the metal with a cloth dipped in alcohol or acetone. This makes sure the surface is clean for cutting, welding, or finishing.

Is it possible to weld different metals together?

Yes, but it depends on the metals. For instance, steel can be welded to stainless steel with the right filler. Welding aluminium to steel needs special methods like explosion welding.

How can you stop metal from bending during welding?

Secure the metal tightly with clamps to keep it steady. Add small tack welds in several spots before doing the full weld. Let the metal cool slowly between welds to avoid bending from heat.

What safety equipment do you need for metalworking?

Wear gloves, goggles, and a welding helmet. Use a long-sleeved shirt and strong boots to protect your body. Make sure your workspace has good airflow to avoid breathing harmful fumes.

See Also

Achieving Superior Quality Through Expert PCBA Manufacturing Methods

Advanced Soldering Methods for Precision in PCB Assembly

Guidelines for Effective PCBA Assembly and Error Prevention

From Prototype To Production: Ensuring Smooth PCBA Design Transition

Comparing Lead-Free and Lead-Based Methods in PCBA Manufacturing