Dismantling a PCB means taking apart circuit boards carefully, and understanding what is the process for dismantling a pcb is essential. This helps save useful parts and materials, stops waste, and supports eco-friendly habits. Recycling PCB parts reduces trash and saves resources.

Did you know PCB e-waste was worth $3.5 billion in 2023? By 2032, it may grow to $7.6 billion because of metal recovery. Recycling PCBs is good for the planet and makes money.

Learning how to dismantle a PCB lets you help this growing green economy.

Key Takeaways

Taking apart PCBs helps reuse parts and cuts down on e-waste. This supports a cleaner environment.

Use tools like soldering irons or shredders to break them down. Hand tools work for small tasks, while machines are faster for big jobs.

Stay safe by wearing gloves, goggles, and masks. Work in a place with good airflow to avoid breathing bad fumes.

Separate materials after breaking them down. Use magnets for metals and chemicals to get gold and other valuable materials.

Recycling PCBs is good for the planet and saves money. It gives useful materials that are worth more than mining them.

Tools and Machines for PCB Dismantling

PCB dismantling machines and how they work

PCB dismantling machines are important for recovering parts and materials. These machines use heat to melt the tin on PCBs. This makes it easier to remove electronic parts from the board. A rotating drum heats up to 200-400 degrees Celsius. As it spins, a scraper removes the parts from the board.

Modern machines have systems to clean harmful gases. They can run on electricity or natural gas, making them flexible. These machines are small, automated, and very fast. They can dismantle a PCB in just three seconds. This makes them perfect for recycling large amounts of PCBs.

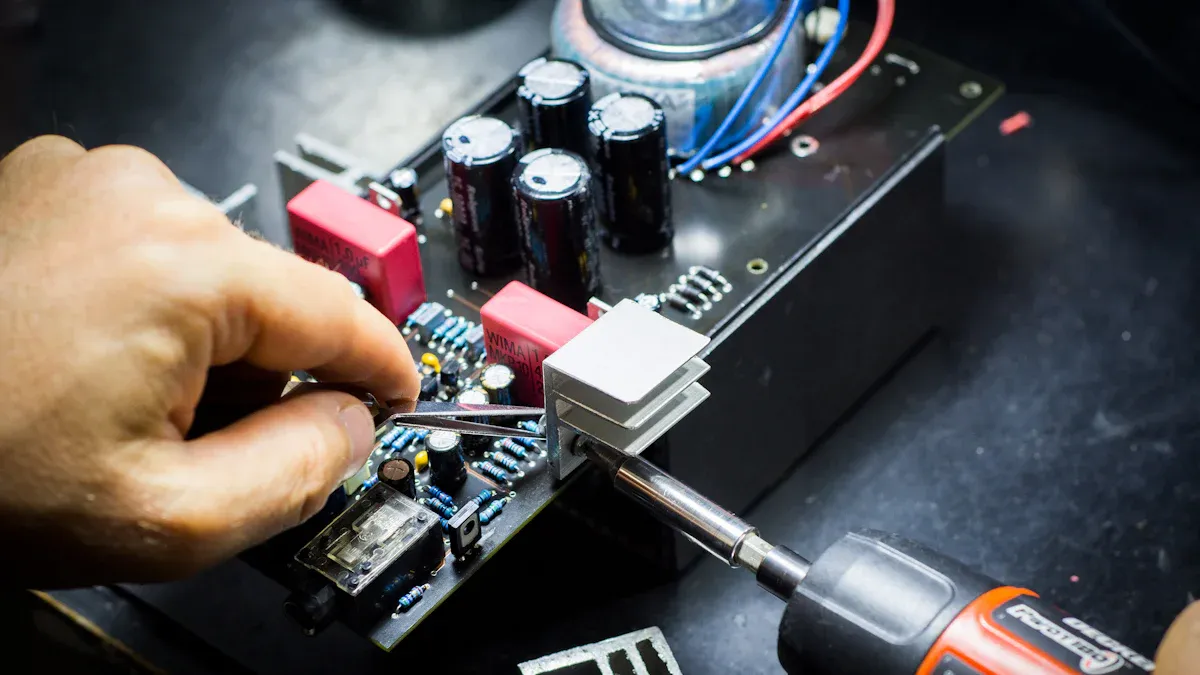

Manual tools for PCB dismantling

For smaller jobs, manual tools are a good option. Tools like screwdrivers, pliers, and soldering irons are commonly used. A soldering iron heats and loosens parts for removal. Pliers help pull out components, and screwdrivers loosen screws and layers. Manual dismantling takes more time but protects valuable parts from damage.

Staying safe while dismantling

Safety is very important when working with PCBs. Always wear gloves, goggles, and masks to protect yourself. Work in a space with good airflow or use tools to remove dust. Don’t eat or drink in the workspace to avoid contamination. Building a barrier can stop dust from spreading. Following these steps keeps you safe and makes dismantling easier.

Tip: Check how much dust is made and how long you work. This helps you decide what safety steps to take.

What is the process for dismantling a PCB

Preparation and safety precautions

Before taking apart a PCB, prepare carefully for safety and efficiency. First, sort PCB materials from clean items. This stops mixing and keeps your workspace tidy. Use sealed drums or plastic sheets to pack PCB waste securely. Label all containers to show they hold PCBs. Quickly send the waste to a proper disposal site.

Protect yourself by wearing gloves, goggles, and masks. These stop harmful substances from touching your skin or being breathed in. Work in a space with good airflow to clear any vapors. Avoid making dust by using gentle methods. After finishing, clean tools to remove leftover PCBs. Learn and teach safe handling steps to lower risks.

Tip: Write down what you removed and where it went. This helps follow rules and track the process.

Heating techniques for component removal

Heating is important when dismantling a PCB. Use a soldering iron or a machine to loosen parts. A soldering iron heats small areas to remove items like resistors. Machines use spinning drums heated to 200-400°C. The heat melts solder, making parts come off fast.

For small jobs, manual tools work well. For bigger tasks, machines save time and are faster. Watch the temperature to avoid damaging parts or releasing fumes. Good airflow helps clear any vapors safely.

Shredding and crushing the PCB

After removing parts, break the PCB into smaller pieces. Special shredders and crushers grind the board into tiny bits. These machines handle tough layers like fiberglass and metal.

Shredding makes the PCB smaller, so valuable materials like copper are easier to get. Crushing also separates recyclable parts from trash. Use the machines in a safe space to reduce dust and noise. Proper shredding and crushing help recycle materials and protect the environment.

Ways to Separate Materials

After breaking the PCB into pieces, materials must be sorted. This step helps recover useful parts like metals and plastics. Different methods are used based on the material type.

Magnetic Separation: Magnets pull out metals like iron and steel. These metals stick to the magnet, making them easy to remove.

Eddy Current Separation: This method separates metals like aluminum and copper. A magnetic field pushes these metals into a different area.

Density Separation: Plastics and glass are sorted by weight. A shaking table or air blower separates light items from heavy ones.

Chemical Processing: Chemicals can dissolve certain materials for better separation. For example, acids remove gold and silver from PCB pieces. Always use chemicals safely and follow rules.

Each method helps recover valuable materials from PCBs. Using all these methods together works best and reduces waste. Proper sorting helps recycling and protects nature.

Tip: Write down what you recover. This helps track your recycling success and ensures nothing is missed.

Outcomes of PCB Dismantling

Recovery of electronic components

Taking apart a PCB helps save useful electronic parts. Items like resistors, capacitors, and microchips can be reused. Careful removal keeps these parts working for new devices. Studies show that sorting and checking materials helps find these parts. This saves resources and reduces the need to make new ones.

Some recovered parts are very valuable. Microchips and processors have metals like gold and silver. These metals are rare and costly, so recovering them is smart. By focusing on saving parts, you help make electronics more eco-friendly and cheaper to produce.

Separation of recyclable materials

After taking apart a PCB, sort the materials. Separate metals, plastics, and glass into groups. Magnets can pull out iron and steel. Eddy currents push out aluminum and copper. Lighter materials like plastics are sorted by weight.

Chemicals can also help get valuable metals. For example, acids can remove gold and silver from PCBs. These methods make sure materials are reused instead of thrown away. Sorting well helps recycle more and reduces trash.

Environmental and economic benefits

Breaking down PCBs helps the planet and saves money. Recycling stops harmful materials in PCBs from polluting soil and water. It protects nature and keeps people safe from toxins.

Recycling PCBs is also good for the economy. Metals like gold and palladium in PCBs are richer than in ores. Modern recycling methods recover these metals better than mining. Recycling is cheaper and greener. By dismantling PCBs properly, you support a cleaner world and save money.

Did you know? Recycling metals from PCBs can be 100 times more valuable than mining. This shows why proper dismantling and recycling are so important.

Taking apart a PCB helps protect nature and save resources. Learning about PCB recycling reduces trash and recovers useful materials. Tools like shredders, heaters, and hand tools make it easier. Steps like heating, breaking, and sorting help get the most materials. Recycling PCBs is good for the Earth and boosts the green economy. Begin recycling PCBs today to help the planet and your neighborhood.

FAQ

Why do we dismantle a PCB?

The main reason is to save useful parts and materials. This helps cut down on electronic waste and saves resources. By doing this, you also help the environment and support recycling.

Can a PCB be taken apart at home?

Yes, small PCBs can be taken apart at home. Use tools like screwdrivers and soldering irons. Always wear safety gear and work in a space with fresh air. For bigger jobs, professional machines are safer and faster.

What safety steps should you take when dismantling a PCB?

Wear gloves, goggles, and a mask to stay safe. Work in a place with good airflow to avoid breathing in fumes. Don’t eat or drink in the workspace to keep things clean.

How do you sort materials after taking apart a PCB?

Use magnets to pull out metals, and separate plastics by weight. Chemicals can help remove valuable metals like gold. Each method helps recover materials and reduces waste.

Why is recycling PCBs good for the economy?

Recycling PCBs gets back valuable metals like gold and copper. These metals are found in higher amounts in PCBs than in ores. Recycling lowers mining costs and supports the green economy. ♻️

Tip: Start with small projects to learn before trying bigger ones.

See Also

Guidelines for Assembling PCBA and Avoiding Mistakes

Comparing Lead-Free and Lead-Based PCBA Production Methods

Excelling in PCBA Production Techniques for Superior Quality

RSJPCBA’s Commitment to Quality in PCB and PCBA

From Prototype to Production: Ensuring Smooth PCBA Design Transition