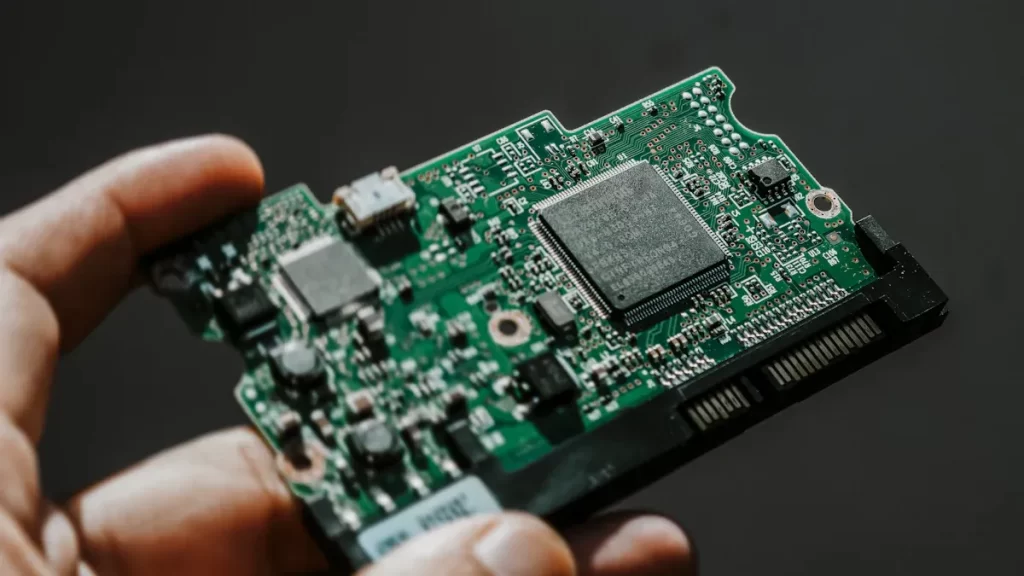

The rise of Industry 4.0 has significantly transformed Industry 4.0 PCBA services. It has enhanced how companies manufacture and design electronic components. Now, you can leverage advanced tools such as IoT, big data, and machine learning to operate more efficiently and effectively. For instance:

IoT enables devices to communicate and gather real-time data.

Big data identifies trends for more intelligent inventory management and repairs.

Machine learning allows machines to operate autonomously, requiring less human intervention.

Choosing the right provider for Industry 4.0 PCBA services is crucial. The ideal partner aligns with your needs, fosters growth, reduces costs, and guarantees high quality. This guide will assist you in making the best choice for your business.

Key Takeaways

Industry 4.0 improves PCBA services by using smart tools like IoT and robots. This makes production faster and more precise.

Picking the right PCBA provider is important. Choose ones with good technology, flexibility, and helpful customer service to fit your needs.

Saving money is key. Check providers for fair prices, good quality, and value without losing service quality.

Quality checks and certifications, like ISO 9001, show that providers follow high standards and make dependable products.

For tricky projects, pick providers with strong skills in your field. They can create custom solutions for your needs.

What Is Industry 4.0 in PCBA Services?

Definition and Key Concepts of Industry 4.0

Industry 4.0 is the fourth big change in manufacturing. It uses advanced digital tools to make systems smarter and more efficient. This approach connects machines, uses automation, and relies on real-time data to improve production.

Key ideas include:

Cyber-physical systems: These connect machines and software, letting them work together easily.

Predictive analytics: By studying past and current data, you can spot problems early and fix them.

Supply chain visibility: Industry 4.0 tools help track products better, speeding up delivery and teamwork.

These changes help businesses work faster, avoid delays, and adjust to market needs quickly.

How Industry 4.0 Enhances PCBA Processes

Industry 4.0 has changed how printed circuit boards are made. It uses new technologies to make production faster and more accurate. For example, IoT helps monitor production lines in real-time. This allows for quick fixes and fewer delays.

Robots and automation are also key. Smart machines can handle complex tasks with little human help. This ensures high-quality work and quicker results. Augmented reality (AR) helps with inspections. Workers can use AR tools to compare parts and find mistakes more easily.

Here’s how different technologies improve PCBA processes:

Technology | How It Helps |

|---|---|

Smart Manufacturing | Boosts efficiency and quality by connecting machines and using real-time data. |

IoT Integration | Tracks production in real-time, prevents breakdowns, and saves energy. |

Advanced Robotics and Automation | Speeds up production and reduces the need for manual work. |

Big Data Analytics and AI | Helps plan better and fix problems before they happen. |

Additive Manufacturing (3D Printing) | Makes prototypes quickly, wastes less material, and creates complex designs. |

Supply Chain Digitization | Improves tracking and teamwork, making operations smoother. |

Enhanced Product Customization | Lets companies create unique products for customers without slowing down. |

These tools keep PCBA processes modern and ready for industry changes.

Benefits of Industry 4.0 in Electronics Manufacturing Services

Using Industry 4.0 in electronics manufacturing brings big benefits. Smart tools help businesses work better, save money, and make higher-quality products.

Some key benefits are:

Efficiency gains: Automated tools reduce mistakes and increase production speed.

Cost savings: Fixing problems early saves money, and 3D printing cuts waste.

Customization capabilities: Companies can make custom products quickly and efficiently.

Real-world examples show these benefits clearly. For instance, AR tools make inspections faster and more accurate. Workers using AR glasses can spot problems right away, keeping quality high.

Studies also back up these advantages. Research by Dalenogare et al. (2018) and Büchi et al. (2020) shows that Industry 4.0 improves factory performance. These findings highlight why adopting these tools is important to stay competitive in electronics manufacturing.

Key Criteria for Evaluating PCBA Providers

Advanced Technology and Automation

When picking a PCBA provider, focus on their technology use. Advanced tools and automation improve production speed and quality. Automation makes assembly faster and reduces mistakes. This leads to quicker deliveries and more reliable products. For example, automated soldering and inspections make work precise and lower defect risks.

Aspect | Description |

|---|---|

Increased Efficiency | Automation speeds up work and reduces errors for faster delivery. |

Enhanced Precision | Robots ensure accurate results with little human involvement. |

Improved Quality Control | Advanced testing finds issues early and keeps quality high. |

Providers using automation often deliver better outcomes. They also use smart algorithms to improve manufacturing steps. This ensures products are consistent in quality. Choosing a provider with modern tools helps you stay ahead in the electronics market.

Scalability for Business Growth

Scalability is vital when choosing a PCBA provider. As your business grows, the provider must handle more work without delays or quality drops. The PCB market is growing fast due to new technology. For example:

PCB Design Software Market may grow from $3.77 billion in 2024 to $11.37 billion by 2032, with a 14.80% growth rate.

PCB manufacturing equipment market could grow at 6.2% yearly from 2024 to 2032.

These trends show why scalable providers are important. They can meet your needs even as production increases.

Cost-Effectiveness and Value

Cost-effectiveness matters when picking a PCBA provider. Check how they balance price, quality, and service. Costs depend on design difficulty, order size, and delivery time.

Cost Factor | Description | Cost Impact |

|---|---|---|

Design Complexity | Layers, parts density, and trace paths. | Complex designs cost more due to extra work. |

Production Volume | Number of PCBs made. | Small orders cost more per unit; big orders save money. |

Turnaround Time | Time needed to finish assembly. | Faster delivery often costs extra. |

Clear pricing is also important. Providers who explain costs help you plan better and avoid surprises. Focus on value, not just price, to get great service within your budget.

Quality Checks and Important Certifications

When picking a PCBA provider, focus on quality checks and certifications. These prove the provider follows rules and makes reliable products. Certifications like ISO 9001 and IPC show they care about high standards. Providers with these certifications usually follow strict rules to meet your needs.

Checking suppliers is also very important. Use these steps to check their reliability:

Do detailed checks to ensure they follow industry rules.

Confirm their manufacturing steps are consistent and reliable.

Use Statistical Process Control during prototypes to track changes.

Regular checks keep quality steady over time. They also build trust between you and the provider. By reviewing suppliers carefully, you can find the best match for your business.

Customer Help and Reliable Service

Good customer help is key to working well with a PCBA provider. You need a provider who solves problems fast and communicates clearly. Tools like surveys and Net Promoter Scores (NPS) can show how good their service is.

Metric Type | What It Shows |

|---|---|

Customer Satisfaction Surveys | Feedback from customers about product quality and support. |

Net Promoter Score (NPS) | Measures if customers would recommend the provider to others. |

Problem Resolution Times | Shows how quickly issues are fixed, proving service reliability. |

Communication Transparency | Checks how clear and honest the provider is when talking to customers. |

Providers with high scores in these areas usually offer great service. Fast problem-solving keeps your work running smoothly. Clear communication builds trust and keeps you updated.

Picking a provider with strong customer help and reliable service ensures smooth teamwork and helps you reach your goals easily.

Comparison of Top Industry 4.0 PCBA Providers

Asteelflash: Leader in Smart PCBA Services

Asteelflash is a top name in Industry 4.0 PCBA. They use advanced tools and smart systems to improve production. Their technology includes IoT, robotics, and big data for better results.

They work with many industries like cars, planes, and electronics. Automation and predictive tools help them reduce mistakes and speed up work. This means better products and on-time deliveries, which are important for staying competitive.

Asteelflash also helps with product design, turning ideas into reality. They can handle both small and large orders. This makes them a great choice for growing businesses. Their solutions are reliable, affordable, and fit your needs.

Jabil: Expert in Electronics Manufacturing

Jabil is a global leader in electronics services. They offer more than just PCB assembly. Their Industry 4.0 tools include automation, real-time tracking, and digital supply chains. These make their production fast and precise.

Jabil has experience in industries like healthcare, telecom, and automation. They focus on quality and innovation to meet high standards. Their design team works with you to create custom solutions for your needs.

Jabil is great at handling tough projects. Their scalable systems let you adjust to market changes without losing quality. They also care about the environment, helping you lower waste while reaching your goals.

Sanmina: Advanced PCBA with Top Technology

Sanmina provides excellent PCBA services using advanced tools. They are known for their quality and have won awards like Nokia’s 2014 Supplier Excellence Award. This shows their focus on reliable products and strict quality checks.

Sanmina uses high-tech testing for better performance. For example, they test backplanes at speeds up to 40 GHz. Robotic testing ensures accuracy and efficiency. These methods meet even the toughest standards.

They also use new materials and methods to improve product performance. Sanmina is trusted for making high-quality PCBs, even for custom needs. They deliver on time and handle complex projects well.

Sanmina offers design, prototyping, and full production services. Their scalable systems help your business grow smoothly. Choosing Sanmina means working with a partner focused on quality, innovation, and customer satisfaction.

Flex: Adaptable and Scalable PCBA Services

Flex is a global leader in electronics manufacturing. They offer flexible PCBA services for different business needs. With over 50 years of experience in 30 countries, Flex helps businesses grow without losing quality or efficiency. Their focus on innovation makes them a trusted partner for all business sizes.

Flex’s scalability comes from advanced manufacturing and constant improvement. They work closely with suppliers and customers to improve quality and cut costs. Using Lean and Six Sigma methods, they reduce waste and speed up production. This ensures better results for your electronics projects.

A unique feature of Flex is their use of digital twins. These are real-time simulations that help improve product designs before production. This saves time and money. They also use advanced software to make manufacturing precise and consistent.

Here’s why Flex is a top choice for scalable PCBA services:

Feature | Benefit |

|---|---|

Continuous Improvement | Works with suppliers and customers to improve quality and lower costs. |

Advanced Manufacturing Tools | Uses simulations and software for efficient and accurate production. |

Global Expertise | Over 50 years of experience in 30 countries ensures reliable and scalable service. |

Lean and Six Sigma Practices | Reduces waste and boosts efficiency for faster production. |

Digital Twins | Simulates products in real-time to save time and reduce costs. |

Flex’s ability to grow with your business makes them a great partner. Their focus on innovation, efficiency, and teamwork ensures reliable electronics manufacturing.

Benchmark Electronics: Tailored Solutions for Complex Projects

Benchmark Electronics is known for solving tough PCBA challenges. They are a top choice for industries needing custom solutions. With over 40 years of experience, Benchmark delivers award-winning designs and complete product services. Their ability to handle complex tasks sets them apart.

Benchmark is skilled in medical device design and development. They offer full services, including design, manufacturing, and testing. This ensures products meet high safety and quality standards. Their cybersecurity expertise protects connected devices, meeting FDA rules and addressing safety concerns.

They also focus on miniaturization, making products smaller and lighter. Whether it’s remote monitoring devices or telemedicine tools, Benchmark ensures secure, connected, and easy-to-use designs. Their innovative approach keeps products aligned with industry trends.

Here’s a closer look at Benchmark’s expertise:

Expertise Area | Benefit |

|---|---|

Medical Device Design and Development | Full services for creating safe and high-quality medical devices. |

Cybersecurity Knowledge | Protects connected devices with threat modeling and FDA compliance. |

Miniaturization Skills | Designs smaller, lighter products optimized for their purpose. |

Remote Monitoring and Telemedicine | Develops secure, connected, and user-friendly healthcare devices. |

40+ Years of Innovation | Proven success in delivering award-winning designs and complete product solutions. |

Benchmark’s focus on solving hard problems makes them a trusted partner. Their dedication to quality and innovation ensures your projects are done with care and precision.

Use Cases and Recommendations

Best Providers for Small Businesses

Small businesses need affordable and flexible electronics manufacturing services. Providers like JLCPCB and PCBWay are great options for this.

JLCPCB: This provider is known for low-cost PCB prototyping and assembly. It’s perfect for startups and small projects. Their fast processes ensure quick delivery without losing quality. But, they have fewer material choices, which may not fit custom needs.

PCBWay: They offer more material options and finishes for customization. Their services include PCB design and component sourcing, meeting various business needs.

Studies show small businesses benefit from focusing on specific customer groups. By targeting a niche, you can better meet customer needs and add value.

Tip: Pick a provider that offers both affordability and customization. This helps your business grow without overspending.

Best Providers for High-Volume Manufacturing

For large-scale production, efficiency and scalability are key. Providers like Flex and Jabil excel with their advanced tools and global experience.

Manufacturing Process | Key Features | Lead Time |

|---|---|---|

CNC Machining | Precise finishing, ready in as little as 2 days. | 5-8 weeks for big orders |

Injection Molding | T1 samples made in 10 days with low minimums. | 5-8 weeks for big orders |

Die Casting | Produces large parts affordably for mass production. | 5-8 weeks for big orders |

Flex uses digital twins and Lean methods to improve production. This ensures high quality even for large orders. Jabil uses real-time tracking and digital supply chains for better efficiency.

Tracking trends is important in high-volume production. It helps predict demand, manage inventory, and plan logistics. By spotting machine issues early, you can schedule repairs and avoid delays.

Note: Spending more on good design at the start saves money later. Better designs lower production costs in the long run.

Best Providers for Complex or Custom PCBA Needs

Specialized providers are needed for complex or custom PCBA projects. Benchmark Electronics and Advanced Circuits are top choices for these tasks.

Provider | Strengths | Services Offered | Specializations |

|---|---|---|---|

Benchmark Electronics | Skilled in medical devices, cybersecurity, and miniaturization | Full design, manufacturing, and testing | Secure devices, high-reliability uses |

Advanced Circuits | Reliable PCBs, great for custom designs | Prototyping, advanced manufacturing, quick turn | Aerospace, defense, complex designs |

Benchmark focuses on healthcare, making secure and connected medical devices. Advanced Circuits is ideal for aerospace and defense, offering reliable and custom solutions.

Case studies show that providers with strong design skills improve product performance. Their expertise ensures high-quality results tailored to your needs.

Tip: Choose a provider with proven success in your industry. This ensures your complex projects are done with care and accuracy.

Recommendations Based on Industry Needs

Picking the right PCBA provider depends on your industry’s needs. Each sector has specific materials, skills, and methods required. Knowing these helps you choose a provider that delivers great results.

Flexible PCBs for Wearables and Cars

Wearable devices and car electronics need flexible PCBs. These boards must use polyimide materials and special tools. Providers with these skills ensure strong and adaptable designs.

High-Frequency PCBs for Telecom and Aerospace

Telecom and aerospace industries need high-frequency PCBs. These boards use low-loss materials and precise manufacturing. Providers with experience in this area improve signal quality and performance.

HDI PCBs for Phones and Computers

Phones and advanced computers often use HDI PCBs. These boards need laser drilling and microvia expertise. A skilled provider ensures compact and powerful designs.

Metal Core PCBs for LEDs and Power Devices

LED lights and power devices work best with metal core PCBs. These boards handle heat well and need advanced bonding techniques. A good provider ensures better cooling and lasting performance.

Special PCBs for Aerospace and Medical Use

Aerospace and medical devices need strict quality and safety checks. Aerospace PCBs must meet tough standards, while medical PCBs need to be safe for the body and sterilized. Providers with AS9100 or ISO 13485 certifications are ideal.

PCB Type | Uses | Key Skills Needed |

|---|---|---|

Flexible PCBs | Wearables, car electronics, medical tools | Polyimide materials, special tools |

High-frequency PCBs | Telecom, radar, aerospace | Low-loss materials, precise manufacturing |

HDI PCBs | Phones, advanced computers | Laser drilling, microvia expertise |

Metal Core PCBs | LED lights, power devices | Heat management, bonding techniques |

Aerospace PCBs | Aerospace, defense | High quality and performance standards |

Medical PCBs | Implants, diagnostic tools | Body-safe materials, sterilization standards |

Tip: Choose a provider with skills that match your industry. This ensures your products meet safety, quality, and performance needs.

Industry 4.0 has changed how PCBA services work. It makes manufacturing smarter, faster, and more efficient. Using tools like IoT, automation, and predictive analytics improves quality and saves money.

When choosing a provider, check their technology, growth ability, costs, and support. Match these with your business needs for the best results.

Think about what matters most to your business. Pick a provider that fits your goals. This choice will help you stay ahead and succeed in the electronics industry.

FAQ

What is the main benefit of Industry 4.0 in PCBA services?

Industry 4.0 makes work faster and more accurate. It uses automation, IoT, and real-time data to reduce mistakes. Predictive maintenance also helps avoid downtime and keeps production steady.

How can I pick the best PCBA provider for my business?

Think about what your business needs most. Check providers for their technology, ability to grow, certifications, and support. Small businesses should focus on saving money. For big or tricky projects, choose providers with advanced tools and experience.

Are Industry 4.0 PCBA services good for small businesses?

Yes, small businesses can use Industry 4.0 tools. Companies like JLCPCB and PCBWay offer low-cost services. They use smart machines to make high-quality products, even for small orders.

What certifications should a trustworthy PCBA provider have?

Look for ISO 9001 for quality and IPC for PCB standards. For special industries, check for AS9100 (aerospace) or ISO 13485 (medical). These prove the provider follows strict rules for safety and quality.

Can Industry 4.0 help with custom PCBA designs?

Yes, it can. Tools like 3D printing and digital twins make custom designs easier. Providers like Benchmark Electronics are skilled at creating unique and complex designs to meet your needs.

See Also

Evaluating Top PCBA Manufacturing Services for 2025

Essential Technologies Shaping PCBA Manufacturing in Today’s Electronics

How to Choose the Right PCBA Manufacturer for You