You might have heard the term PCB in electronics. But what does PCB stand for in electronics? It stands for Printed Circuit Board. This important board is the base of modern devices. It holds electronic parts and lets signals move between them. Without PCBs, making devices like phones or computers would be very hard. PCBs make electronics easier to design and keep connections strong.

Key Takeaways

PCB means Printed Circuit Board. It connects and organizes electronic parts in devices.

There are different types of PCBs, like single-layer, multi-layer, and flexible ones. Each type is used for specific electronic needs.

Thin metal lines, called traces, on a PCB move electrical signals. These signals help parts work together smoothly.

Testing and checking PCBs is very important to make sure they work well. This is especially true for healthcare and car industries.

PCBs help make devices smaller and smarter. They also make electronics more efficient.

What is a printed circuit board?

Definition of a printed circuit board

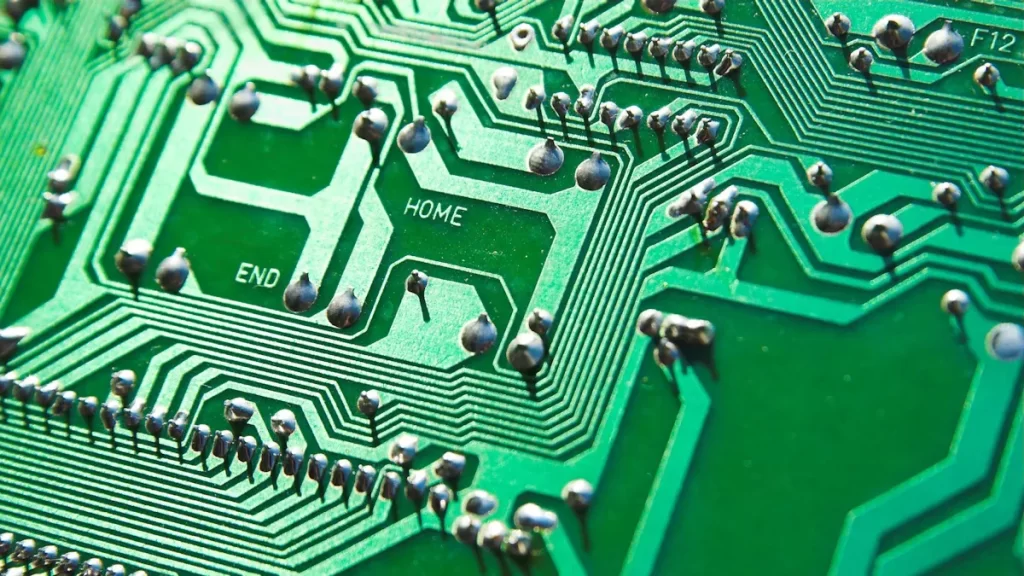

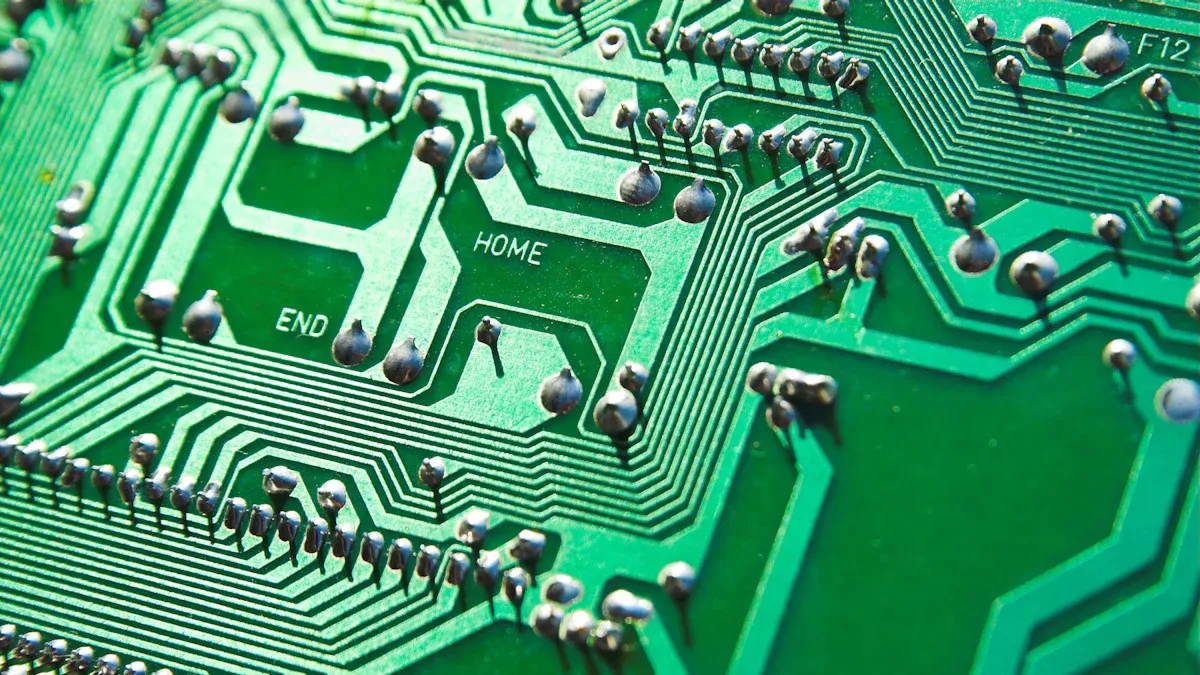

A printed circuit board (PCB) is key to modern electronics. It connects and organizes electronic parts in devices. You can find PCBs in phones, computers, and medical tools. They use conductive paths, called traces, to move electrical signals between parts. This setup helps devices work smoothly and dependably.

Tip: Imagine a PCB as the “brain” of a device. It sends signals to make all parts work together.

Basic structure and layers of a PCB

A PCB has several layers, each with a job to do:

Substrate: The strong base layer, often made of fiberglass.

Copper Layer: This layer carries signals through conductive traces.

Solder Mask: A protective layer that stops unwanted contact.

Silkscreen: The top layer with labels and markings for easy identification.

PCBs come in different types, like single-layer, double-layer, or multi-layer. Multi-layer PCBs are common in advanced devices because they save space and allow complex designs.

Key Factors Driving PCB Changes | Description |

|---|---|

Custom Solutions for Industries | Tailored designs meet specific needs for complex devices. |

Certification Standards | Following rules ensures products are accepted in the market. |

Smart Tech and AIoT Growth | New technologies change how PCBs are designed. |

High Reliability Demand | Sectors like healthcare need durable and dependable PCBs. |

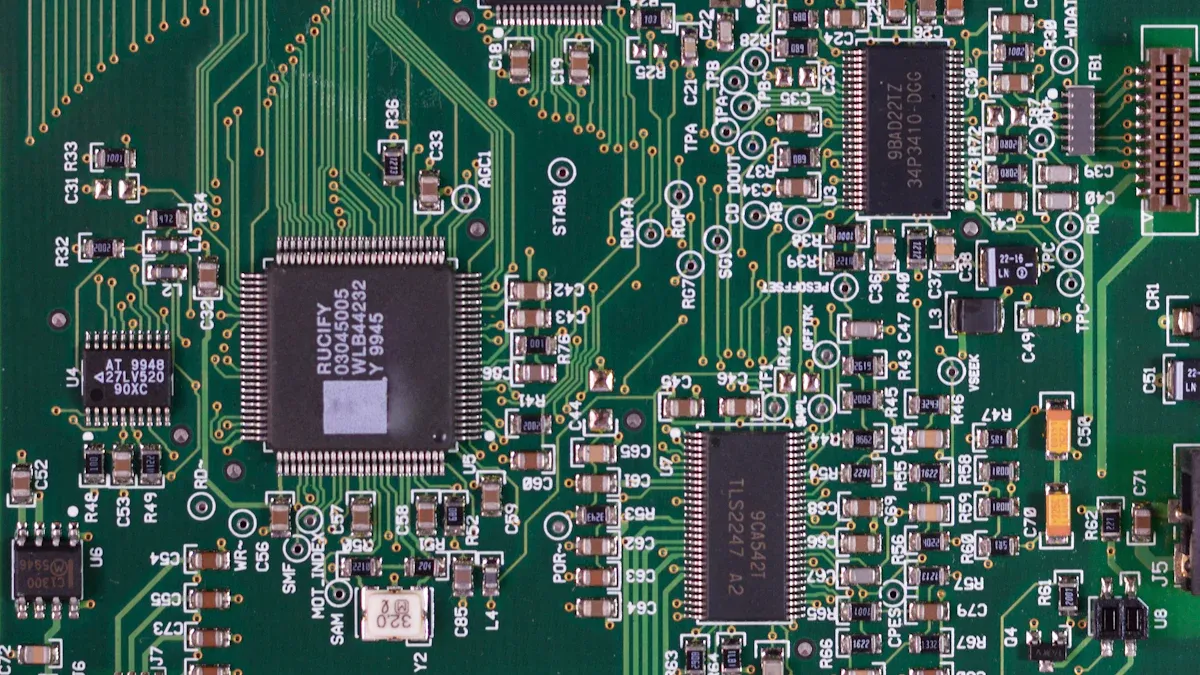

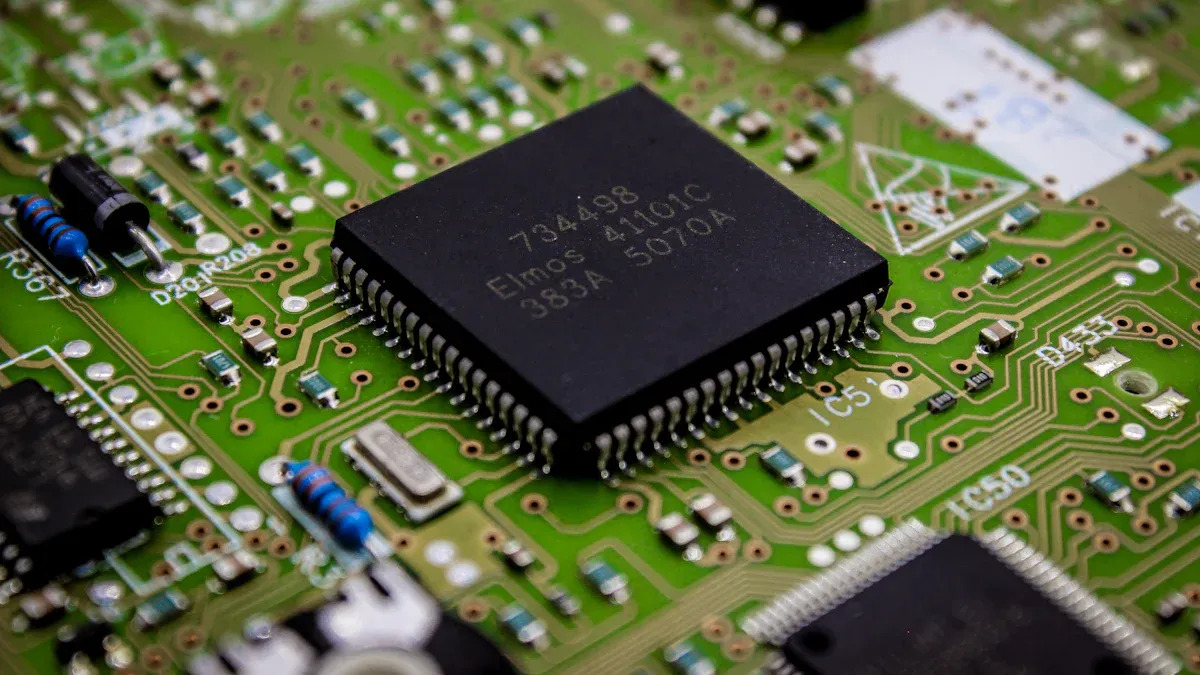

Common components on a PCB

PCBs hold many parts, each with a special job:

Resistors: Control how much current flows.

Capacitors: Store and release energy when needed.

Diodes: Let current flow in only one direction.

Integrated Circuits (ICs): Tiny circuits that handle complex tasks.

Connectors: Link external devices to the PCB.

These parts are attached to the PCB using methods like surface-mount technology (SMT) or through-hole mounting. Engineers test the PCB to make sure it works well and meets standards.

Process | Description |

|---|---|

Component Assembly | Parts are soldered onto the PCB using SMT or through-hole methods. |

Testing and Quality Control | Engineers check for problems in soldering or parts. |

Design Review and BOM Check | Experts look for issues in design and materials before production. |

Component Sourcing | Suppliers find high-quality parts and avoid fake ones. |

PCB Production | Making the PCB based on design plans and requirements. |

Electronics Assembly | Attaching parts to the PCB for strong and reliable connections. |

Final Product Assembly | Putting all parts together and preparing the product for use. |

Note: Good parts and careful assembly make devices reliable. Always test and check quality during production.

How does a PCB function?

The role of conductive pathways in a PCB

Traces, or thin copper lines, are like lifelines for a PCB. They carry electrical signals between parts of the board. Imagine them as roads connecting cities for smooth traffic. Traces help signals reach the right components without problems. Engineers design these paths carefully to avoid overlaps or short circuits. Special software is used to plan these paths for better performance.

Tip: Good traces improve how well your device works. Better designs mean fewer problems and more reliability.

How PCBs connect and support electronic components

A PCB holds and connects electronic parts securely. It uses traces to link components like resistors and capacitors. Soldering keeps these parts firmly attached to the board. This setup creates strong connections that don’t break easily. The PCB also keeps everything neat and organized. This makes fixing or checking for problems much simpler.

Note: Without PCBs, connecting parts by hand would take a lot of time and could lead to mistakes.

Types of PCBs (e.g., single-layer, multi-layer, flexible)

PCBs come in different types for different uses. Single-layer PCBs are simple and cheap, great for basic devices like calculators. Multi-layer PCBs have stacked layers for advanced gadgets like smartphones. Flexible PCBs can bend, making them ideal for wearable devices. Each type helps engineers build creative and useful products.

PCB Type | Features | Common Uses |

|---|---|---|

Single-layer | Easy to make, low cost | Simple electronics |

Multi-layer | Compact, handles complex circuits | Phones, computers |

Flexible | Lightweight, bendable | Wearable devices |

Fun Fact: Flexible PCBs are often used in medical tools because they fit into small spaces.

The role of PCBs in electronics

Supporting and organizing electronic components

A printed circuit board is like the backbone of electronics. It holds parts such as resistors, capacitors, and integrated circuits securely. This keeps components from moving or getting loose. The PCB arranges these parts neatly, making it easier for engineers to work on devices.

PCBs also make building devices simpler. Instead of connecting each part by hand, the PCB provides a ready-made layout. This reduces mistakes and speeds up production. For example, in smartphones, the PCB helps all parts fit perfectly in a small space.

Tip: Neatly arranged parts on a PCB make fixing and upgrading easier.

Enabling compact and efficient designs

Modern gadgets need to be small and smart. PCBs help by stacking multiple layers together. Multi-layer PCBs are used in laptops and tablets to save space and handle complex circuits. Flexible PCBs can bend, making them great for wearables or medical tools.

PCBs also improve energy use. By keeping parts close, they reduce energy loss when signals move. This makes devices like smartwatches last longer and work better.

Fun Fact: Flexible PCBs are used in space tech because they handle tough conditions and save space.

Ensuring reliable electrical connections

A PCB’s main job is to keep signals flowing smoothly. Copper traces on the board act like tiny roads for electricity. These paths are carefully planned to avoid problems like short circuits.

Manufacturers test PCBs to ensure they work well. For example, continuity tests check if connections are complete. High-potential tests make sure nearby paths stay separate. Stress tests check how the PCB handles heat, cold, or shaking.

Testing Method | Purpose |

|---|---|

Continuity testing | Checks if connections are complete |

Resistance measurements | Tests the quality of plating |

High-potential (hipot) testing | Ensures nearby paths don’t touch |

Signal integrity testing | Checks performance for fast signals |

Environmental stress testing | Tests under heat, cold, or vibration |

Insertion force measurements | Tests physical strength |

Wear testing | Checks durability with repeated use |

Adhesion testing | Tests how strong plated layers stick |

Bend and stress testing | Checks if edges can handle bending |

Impact and vibration resistance evaluation | Tests strength against shocks |

Manufacturers follow strict rules like IPC-A-600 and ISO 9001 to ensure quality. These rules make sure your PCB will last and work well.

Note: Reliable PCBs are crucial for industries like healthcare and cars, where failure can be dangerous.

Why are PCBs essential in modern technology?

Examples of devices that use PCBs

You use gadgets with printed circuit boards daily. Phones need PCBs to link processors, memory, and sensors. Computers depend on multi-layer PCBs for storing data and running tasks. Medical tools like heart monitors use PCBs for accuracy and dependability.

PCBs are also found in home electronics. TVs, microwaves, and washing machines use them to work properly. Even toys and remotes have PCBs to function smoothly. These boards make devices smarter, quicker, and more reliable.

Fun Fact: Without PCBs, gadgets would be bigger and less useful.

Contribution to innovation and miniaturization

PCBs changed how electronics are made. They help shrink devices while boosting their features. Multi-layer PCBs stack circuits to save space and fit complex designs. Flexible PCBs bend easily, making them great for wearables and medical implants.

Smaller PCBs led to big tech advances. Phones fit strong processors into slim cases. Smartwatches hold sensors, screens, and batteries in tiny spaces. PCBs make these designs possible by keeping parts organized.

Tip: Small PCBs help create portable and lightweight devices.

Importance of PCBs in various industries

PCBs are important in many fields. Consumer electronics use them in laptops, cameras, and gaming systems. Cars rely on PCBs for electric engines, navigation, and safety tools. Space tech uses strong PCBs for satellites and aircraft systems.

Healthcare uses PCBs in life-saving machines and diagnostic tools. Factories use PCBs to automate tasks and improve production. Even solar panels and wind turbines need PCBs to manage energy.

Industry | PCB Uses |

|---|---|

Consumer | Phones, TVs, gaming systems |

Automotive | Electric engines, sensors, displays |

Aerospace | Satellites, aircraft systems |

Healthcare | Heart monitors, imaging machines |

Renewable Energy | Solar panels, wind turbines |

PCBs help devices work well in tough conditions and drive progress everywhere.

Printed circuit boards (PCBs) are key to modern electronics. They hold and link parts, helping devices work well and last long. With copper lines and layered setups, PCBs make small and smart gadgets like phones and medical tools possible.

To keep them working well, makers use special tests. Automated optical inspection (AOI) finds surface flaws. Thermal shock tests check if they can handle extreme heat or cold. These tests prove PCBs are strong and dependable, which is why they are vital in healthcare, cars, and space tech.

Without PCBs, making the tech you use every day would be very hard. They help devices get smaller, smarter, and stronger.

FAQ

What does PCB stand for?

PCB means Printed Circuit Board. It is a flat board that links and holds electronic parts. PCBs are found in almost all gadgets, like phones and medical tools.

How many layers can a PCB have?

PCBs can have one or more layers. Single-layer PCBs are simple and cheap. Multi-layer PCBs stack layers for harder circuits. Flexible PCBs bend to fit tight spaces, perfect for advanced devices.

Why are PCBs important in electronics?

PCBs arrange and connect electronic parts. They make sure connections work well and allow smaller designs. Without PCBs, devices like laptops would be bigger and less useful.

Tip: PCBs save energy by lowering signal loss between parts.

What materials are used to make PCBs?

PCBs use fiberglass for strength, copper for signals, and a solder mask for safety. These materials make PCBs tough and help signals move easily.

Can PCBs be recycled?

Yes, PCBs can be recycled. Special methods recover valuable metals like copper and gold. Recycling cuts down on waste and helps the planet. Always recycle old electronics properly.

♻️ Fun Fact: One ton of PCBs can give back 1 kilogram of gold!

See Also

Exploring PCB And PCBA: Essential Differences To Understand

Diverse Applications Of Sub PCBA In Electronics And More

Benefits And Drawbacks Of Implementing PCBA In Electronics

The Significance Of PCBA In Industrial Automation Explained

Innovative Technologies Shaping PCBA Production In Today’s Electronics