Choosing the best surface mount technology (SMT) assembly services is crucial. It impacts the speed, cost, and quality of your products. Top providers of SMT assembly services offer numerous advantages:

Utilization of advanced tools and modern SMT machines.

Cost savings through large-scale production.

Quicker product launches, allowing you to concentrate on new ideas.

Flexibility in adjusting production to meet your specific needs.

High-quality assembly for dependable products.

In 2025, SMT assembly services companies must rapidly enhance their capabilities to remain competitive. With improved automation and intelligent quality checks, selecting the right SMT assembly services provider can significantly contribute to your success.

Key Takeaways

Picking the right SMT provider affects speed, cost, and quality.

Choose companies with modern tools and strict quality checks for reliable products.

Check costs by reviewing expenses to get the best deal.

Flexible and scalable production helps meet changing project needs.

Great customer support improves success with quick help and solutions.

Understanding Surface Mount Technology (SMT) Assembly Services

What is SMT Assembly?

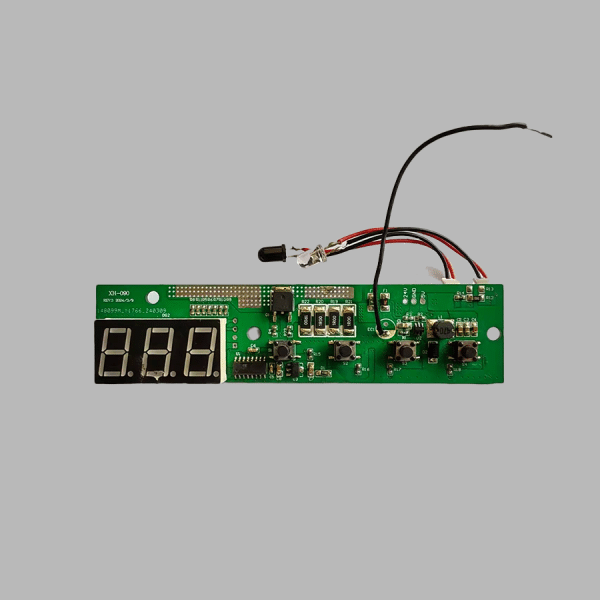

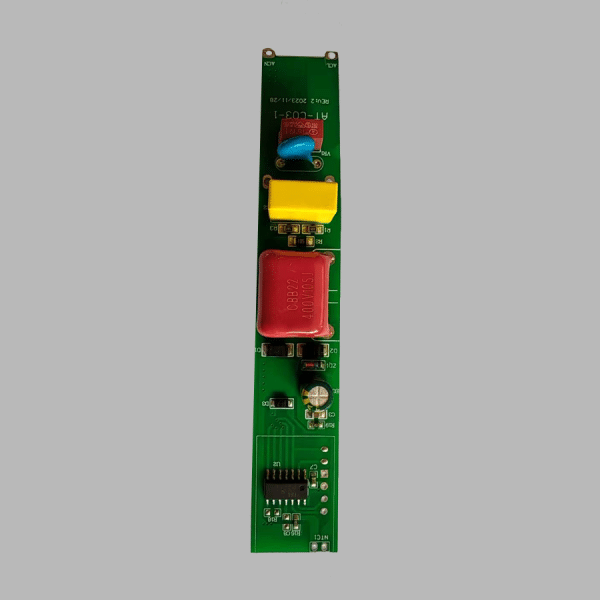

Surface mount technology (SMT) assembly places parts on circuit boards. Unlike older methods, it skips drilling holes for components. Instead, it uses advanced tools to attach parts like resistors and chips. This method makes devices smaller, lighter, and more efficient.

SMT assembly uses different parts like chips and flat packages. It also includes ball grid arrays (BGAs) and small outline packages. These parts save space and improve how circuit boards work. By using modern tools, SMT assembly ensures accuracy and reliability in electronics.

Why is SMT Assembly Critical for Modern Electronics?

SMT assembly is key to making today’s electronic devices. It helps create smaller and faster products. Managing static electricity during assembly is very important. Without control, devices can break during production or use. Tools like grounding wires and mats help prevent damage.

A good static control program keeps devices safe and customers happy. Certifications for static control give companies an advantage. Businesses that focus on this ensure their products are safe and reliable, which is crucial in a competitive market.

Common Applications of SMT PCB Assembly

SMT PCB assembly is used in many industries. It powers gadgets like phones, tablets, and smartwatches. In cars, it supports safety systems and entertainment features. Medical tools like monitors and scanners also depend on SMT assembly for their small designs.

SMT assembly is also vital in factories, airplanes, and communication systems. It works well with tiny parts, making it great for complex designs. Whether for small tests or big productions, SMT assembly ensures fast and scalable manufacturing.

Key Criteria for Comparing SMT Assembly Service Providers

When picking an SMT assembly company, check important factors. These factors help ensure your products are high-quality, affordable, and scalable. Below are the main things to think about.

Technological Capabilities

A company’s technology affects how well they make products. Modern SMT assembly uses advanced tools for small and complex designs. Companies with fast machines and smart inspection tools do better work.

Some key advancements in the industry include:

New soldering methods like laser soldering for better accuracy.

AI tools that check quality and improve production speed.

Support for flexible electronics, great for creative designs.

3D printing for custom circuit board assembly.

Tiny parts that make smaller and more efficient boards.

Look for companies with experience in your product type. Also, check if they have certifications like ISO 9001. These show they follow industry rules and care about quality.

Cost-Effectiveness

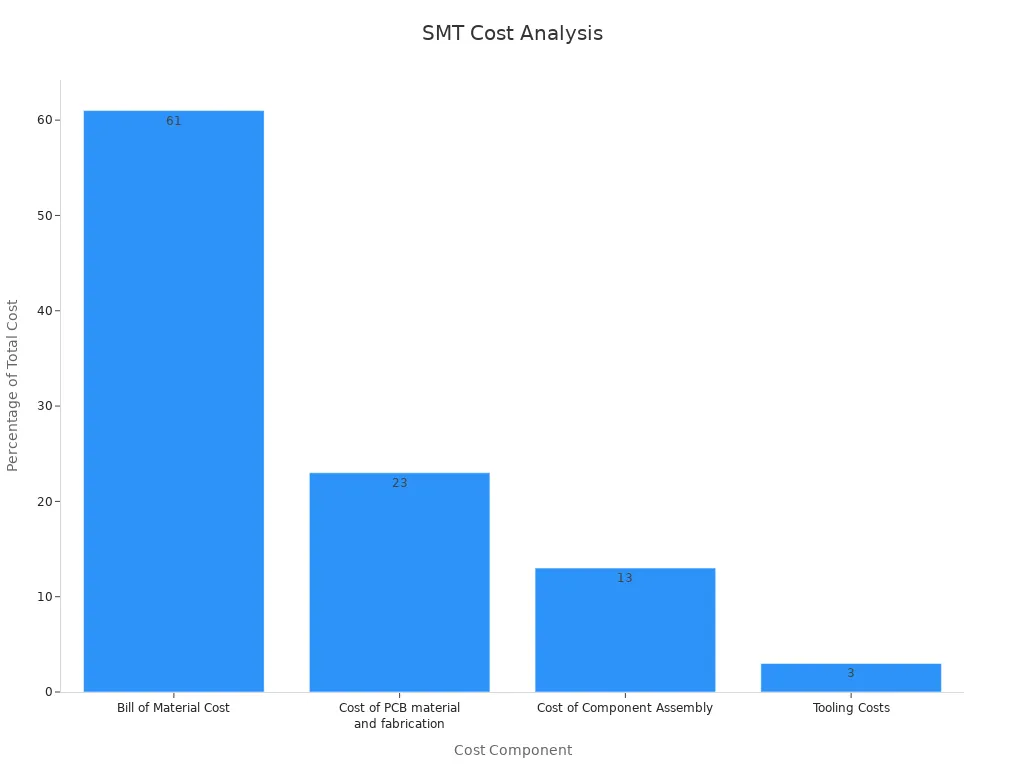

Cost is a big factor when choosing an SMT assembly company. You need good quality at a fair price. A cost breakdown helps you see where money is spent.

Cost Component | Percentage of Total Cost |

|---|---|

Bill of Material Cost | 61% |

Cost of PCB material and fabrication | 23% |

Cost of Component Assembly | 13% |

Tooling Costs | 3% |

Most costs come from materials and making the PCB. To save money, find companies with good prices and quality. Some companies give discounts for large orders, which is great for big projects.

Quality Control Standards

Quality checks are very important in electronics. A good SMT assembly company should have strong quality control steps. These steps include:

Checking parts and early products to ensure stability.

Inspecting circuits during production to catch problems early.

Testing final products before shipping to customers.

Keeping records to prove they meet quality standards.

Testing products in tough conditions to check durability.

Fixing problems to stop them from happening again.

Companies with traceability can find and fix defects quickly. This builds trust and ensures better quality. Picking a company with strict quality checks reduces errors and helps your products succeed.

Production Flexibility and Scalability

When picking an SMT assembly company, flexibility and scalability are key. These factors show how well they can adjust to your needs. A flexible process lets you work with different designs and parts. Scalability means production can grow as demand rises.

Modern SMT companies use advanced machines to meet these needs. These machines handle many components and circuit board designs. They also scale up to support growing businesses. For example:

Scalable machines increase production without losing quality.

Flexible systems adjust to new designs and technologies.

These features help you stay ahead in a fast-changing market.

Using advanced SMT tools helps manufacturers prepare for future challenges. This leads to faster production, lower costs, and better quality. When choosing a provider, pick one with modern equipment and proven flexibility.

Tip: Find SMT companies offering custom solutions. This ensures they can handle both small and large projects.

Customer Support and Service

Good customer support is vital for successful SMT assembly projects. A dependable company helps with design, production, and after-sales services. Quick problem-solving reduces delays and keeps quality high.

Key metrics can measure a company’s support quality. These show how reliable and efficient their service is. For example:

Performance Indicator | Description |

|---|---|

First Pass Yield (FPY) | Shows the percentage of units passing inspection without fixes. |

Defect Density | Counts defects per unit area; fewer defects mean better control. |

Cycle Time | Measures how long a unit takes to finish assembly. |

Mean Time Between Failures | Tracks product reliability and finds potential issues. |

Top SMT companies perform well in these areas, ensuring high-quality products. They also offer easy communication, like account managers or 24/7 support. This helps solve problems quickly and keeps things running smoothly.

Note: Pick a provider focused on quality and customer satisfaction. This ensures your projects are done on time and meet your needs.

Detailed Comparison of Leading SMT Assembly Providers

ASM Assembly Systems: Advanced Automation and Precision

ASM Assembly Systems is known for its advanced automation. They focus on speed and accuracy in SMT assembly. Their SIPLACE TX modules can place 78,000 tiny parts per hour. This ensures fast production without losing quality. The SIPLACE BulkFeeder removes the need for reels, making work easier and reducing mistakes.

ASM also improves processes with smart tools. The ASM ProcessExpert system adjusts and stabilizes SMT tasks automatically. The ASM ProcessLens checks print quality in real time. This 5D SPI system ensures precise and flexible assembly, perfect for detailed work.

Technology | Description |

|---|---|

SIPLACE TX placement modules | Places 78,000 parts per hour, ensuring speed and accuracy. |

SIPLACE BulkFeeder | Feeds loose parts, removing the need for reels. |

ASM ProcessExpert | Automatically improves SMT processes for better results. |

ASM ProcessLens | A 5D SPI system that checks print quality live for precision. |

Tip: Choose ASM Assembly Systems for fast, precise, and automated manufacturing.

Yamaha Motor IM: High-Speed SMT PCB Assembly Solutions

Yamaha Motor IM provides fast SMT PCB assembly services. Their systems reduce defects and improve product quality. Pre-reflow inspections catch problems before solder hardens. This stops defective products from being made in large numbers.

Yamaha’s inspection tools are very accurate. They use a 5-µm high-resolution lens to find defects. This ensures reliable quality checks, even in large-scale production.

Feature | Description |

|---|---|

Defect Minimization | Catches defects early to ensure better product quality. |

Pre-Reflow Inspection | Finds issues before solder hardens, avoiding bad products. |

High-Performance PCB Inspection | Offers consistent quality with advanced inspection tools. |

High-Speed Inspection | Uses a 5-µm lens for precise defect detection. |

If you need speed and quality, Yamaha Motor IM is a great choice. Their focus on reducing defects ensures reliable results for your projects.

JUKI: Cost-Effective and Reliable SMT Assembly

JUKI is known for affordable and dependable SMT assembly. Their machines balance cost and performance well. They work with many parts and circuit board designs, offering flexibility.

JUKI handles both small and large production needs. Their equipment keeps quality steady, whether for prototypes or mass production. This makes them a good choice for businesses with changing demands.

JUKI also focuses on quality checks during assembly. Their tools ensure every product meets strict standards. This helps deliver reliable items to customers.

Note: JUKI is a smart pick for businesses wanting quality at a fair price.

Panasonic Factory Solutions: All-in-One PCB Assembly Services

Panasonic Factory Solutions provides complete services for making circuit boards. Their turnkey PCB services handle everything, from design to production. This makes your work easier and keeps quality steady throughout the project.

Panasonic’s SMT assembly stands out for its advanced tools and support. Their machines are fast and precise, perfect for tricky designs. For instance, their NPM-W2S series uses two lanes to boost speed without losing accuracy. This setup helps you grow production as your business expands.

A big part of Panasonic’s service is their focus on quality. Their systems check for mistakes during assembly and fix them right away. This ensures every board meets strict standards. Panasonic also cares about the environment. Their energy-saving machines and green practices lower harm to nature while keeping great performance.

If you need a trusted partner for PCB assembly, Panasonic Factory Solutions is a great choice. Their all-in-one services save time, cut costs, and deliver top-quality results.

Fuji Machine Manufacturing: Smart Robotics and AI Technology

Fuji Machine Manufacturing leads with its use of robots and AI in assembly. Their advanced systems are precise and efficient, making them ideal for modern electronics.

AI is key to Fuji’s SMT solutions. It improves quality by reducing mistakes in placing parts and soldering. AI-powered machines learn from data to predict and fix problems. For example, AI maintenance reduces downtime and keeps production running smoothly.

Fuji works with Cybord to improve their services further. By using Cybord’s VisualAI technology, they ensure parts are reliable and meet high standards. This partnership boosts quality and traceability in PCB assembly.

Robots are also important in Fuji’s systems. Their machines use advanced robotics to handle tough assembly tasks accurately. Together, AI and robotics help manufacturers make high-quality products quickly.

To stay ahead in electronics, Fuji Machine Manufacturing offers the tools you need. Their focus on innovation makes your assembly process efficient, reliable, and ready for the future.

Future Trends in SMT Assembly

New Developments in Automation and Robotics

Automation and robots are changing how SMT work is done. Robotic arms now do jobs like feeding parts and assembling with great accuracy. Conveyor systems help by moving items faster and making work smoother. Cobots, or helper robots, work with people to check quality and fix mistakes. These tools save money and make production more reliable.

For instance, companies like PCBGOGO use robotic assembly lines. Their advanced systems place parts perfectly, reducing mistakes and speeding up work. Tools like pick-and-place machines and inspection systems make SMT faster and better.

Innovation Type | What It Does |

|---|---|

Robotic Arms | Move materials, feed parts, and assemble with speed and accuracy. |

Automated Conveyor Systems | Make SMT assembly lines faster and more flexible. |

Collaborative Robots (Cobots) | Help people with loading parts, fixing errors, and checking quality. |

Progress in Miniaturization and Precision

Smaller and better devices need new SMT methods. Tiny parts need exact placement, which is now easier with better stencils and AI tools. High-density circuit boards are common, so makers use new tech like flip-chip bonding for small designs.

Smart factories are helping this trend grow. Connected systems watch production live to ensure everything is correct. Better inspection tools also help place tiny parts perfectly. These changes let you make smaller, smarter devices without losing quality.

Going Green with SMT Assembly

Eco-friendly practices are becoming important in SMT work. Companies now use energy-saving methods to cut power use. They also recycle more to keep waste out of landfills. Rules like RoHS and REACH make sure production is safer for the environment.

Sustainability Metric | What It Measures |

|---|---|

Energy Management | Tracks how much energy is saved during production. |

Waste Reduction | Measures how much waste is kept out of landfills. |

Carbon Footprint | Counts greenhouse gases made during operations. |

By focusing on green practices, you can help the planet and improve your work process. These steps save resources and make production more efficient.

Integration of AI and Machine Learning in Quality Control

AI and machine learning are changing how quality control works in SMT assembly. These tools find defects faster and more accurately than older methods. AI looks at large amounts of data to spot problems humans might miss. This makes your products more reliable.

Machine learning gets smarter over time. It uses past inspections to predict future issues. For example, AI systems check solder joints, part placements, and circuit connections live. This lowers the chance of bad products reaching customers.

Some companies already use AI for better quality control. One $50 billion communications company had problems with faulty radios. They tested AI inspection on 1,000 units and found major defects like wrong buttons and missing labels. AI saved time and reduced worker needs, paying off in just one month.

AI also improves traceability in SMT processes. It keeps detailed records of inspections, helping you fix problems quickly. This boosts efficiency and builds customer trust. Adding AI and machine learning to your systems ensures high-quality results and lower costs.

Tip: Work with SMT providers using AI-based quality control. This helps you deliver reliable products and stay ahead.

Choosing the right SMT provider is very important. Companies like ASM and Fuji use advanced tools for great results. Modern SMT processors work at over 80% efficiency, handling tough tasks like machine learning. Each company has special strengths. Yamaha focuses on reducing defects, while Panasonic offers complete solutions. Think about your project’s size, budget, and quality needs. Pick a provider with experience and flexibility. This ensures dependable and affordable results that fit your goals.

FAQ

What makes SMT assembly better than older methods?

SMT assembly skips drilling holes in circuit boards. This makes it quicker and allows for smaller, lighter devices. It also supports compact designs needed for gadgets like phones and medical tools.

How can I pick the best SMT assembly provider?

Look at their technology, costs, and quality checks. Choose providers with certifications like ISO 9001. Check if they can handle growing production and offer good support. These steps help you get dependable results.

Can SMT assembly work for small projects?

Yes, many SMT companies can handle small projects. They use advanced machines that adjust to different designs and sizes. This lets you test ideas or make small batches without losing quality.

Why is quality control important in SMT assembly?

Quality control ensures products work well and meet standards. It includes checking parts, testing during production, and inspecting finished items. Good quality control prevents problems and keeps customers happy.

Are SMT assembly services good for the environment?

Many SMT companies now use eco-friendly methods. They save energy, recycle materials, and follow green rules like RoHS. These practices protect the planet while keeping production high-quality. Choosing such companies helps the environment.

See Also

Understanding Surface Mount Technology: A Simple Overview

Choosing Between SMT And Through-Hole PCB Assembly Methods

Recent AI Innovations In RSJPCBA Design And Production

Comparing Turnkey PCBA And Consignment Manufacturing For 2025

Key Applications Of Through-Hole Technology In 2025 Electronics