In aerospace, safety and accuracy are very important. AS9100 certified PCB assembly helps ensure that PCB assemblies meet strict safety rules. AS9100 certified manufacturers produce reliable products. This certification combines ISO 9000 rules with additional aerospace requirements. Many suppliers don’t have this certification, but those who do are viewed as trustworthy and reliable. Adhering to these standards ensures that products meet top industry benchmarks. This builds trust and enhances performance.

Key Takeaways

AS9100 certification makes sure aerospace PCBs are safe and high-quality.

Certified makers are seen as reliable, building trust with aerospace clients.

Using AS9100 rules lowers fake parts risks and makes products work better.

Regular checks and improvements are needed to keep AS9100 certification.

Working with AS9100 certified suppliers improves your supply chain and helps you compete in aerospace.

What Is AS9100 Certification?

AS9100 certification is a worldwide standard for quality in aerospace. It builds on ISO 9001 but adds aerospace-specific rules. This ensures manufacturers follow strict safety and reliability standards. These rules are very important for making aerospace PCBs.

Overview of AS9100 Standards

AS9100 standards were made to solve aerospace manufacturing problems. They replaced older AS9000 standards and include ISO 9001 ideas. AS9100 adds extra rules focused on safety and quality. Big aerospace companies require AS9100 certification to work with suppliers.

Key parts of AS9100 standards include:

Focus on safety and stopping fake parts.

Importance of ethics and human roles in quality.

Clear processes to meet customer needs.

Keeping good records and having enough resources.

Relevance of AS9100 to Aerospace PCB Manufacturing

AS9100 certification is crucial for safe and reliable aerospace PCBs. These PCBs must meet strict rules to avoid failures that risk lives. AS9100D focuses on safety and stops fake parts in the PCB process.

Getting AS9100 shows a company follows top industry practices. It also proves they make high-quality products, which is key in aerospace electronics.

Key Features of AS9100D Certification

AS9100D certification has features that improve aerospace product quality. These include:

Key Feature | How It Helps Product Quality and Performance |

|---|---|

Risk-based management process | Helps make smart choices for safety and quality |

Focus on product safety | Pushes suppliers to show safety efforts, boosting reliability |

Understanding process impacts | Teaches workers their role in keeping quality high |

Considering human factors | Deals with stress and fatigue to lower mistakes |

Accountability in performance | Tracks progress to keep improving quality |

By following these rules, companies ensure safety, reliability, and efficiency. AS9100D certification meets aerospace rules and builds trust by showing a promise to do great work.

Why AS9100 Certification Matters in Aerospace PCB Manufacturing

Ensuring Safety and Reliability

Safety and reliability are crucial in aerospace manufacturing. AS9100 certification ensures every PCB assembly step follows strict safety rules. It requires manufacturers to use a strong quality system to reduce risks. This system ensures products work well and stay consistent. For example, AS9100-certified PCBs go through tough checks. These include optical inspections and electrical tests after being used for a while. These steps make sure the final products are safe and reliable.

“Getting AS9100 certification isn’t just about following rules. It shows we are dedicated to making the best and safest products for space. It involves a deep review of our processes to meet tough aerospace needs.”

By following AS9100 standards, manufacturers avoid mistakes that could harm important missions. This focus on safety saves lives and helps aerospace missions succeed.

Meeting Regulatory and Industry Standards

Following rules and industry standards is key in aerospace work. AS9100 certification matches global standards, helping companies compete worldwide. It also handles special aerospace needs like stopping fake parts and tracking parts in the supply chain.

Benefit of Compliance | Description |

|---|---|

Competing globally | Certification helps companies join international markets with trusted credentials. |

Stopping fake parts | AS9100D adds rules to improve safety and manage risks better. |

Planning for growth | Continuous improvement helps companies grow and stay strong. |

Safety checks in aviation highlight why AS9100 certification is vital. These checks review safety steps to ensure companies follow all rules. Companies without certification may lose business and hurt their reputation. Certified companies, however, gain trust and stand out by showing their focus on quality.

Enhancing Quality and Operational Efficiency

AS9100 certification helps improve quality and efficiency in aerospace PCB work. It focuses on processes, helping companies find problems and deliver better products. Certified companies can cut waste, save money, and work faster.

Better efficiency in operations

Less waste produced

Happier customers, leading to more profits

Ongoing improvements, lowering costs over time

The certification also supports smart decisions using data. This helps solve problems and save money. For example, Cirexx International earned AS9100D certification in four months. A three-day audit found only three small issues. This shows how AS9100 certification leads to excellent work.

By meeting AS9100 standards, companies improve quality and earn client trust. This trust builds long-term partnerships and keeps customers coming back. It also strengthens the company’s place in the competitive aerospace market.

Building Trust with Aerospace Clients

In aerospace, trust is a must, not just a choice. Working with AS9100 certified PCB assembly makers gives confidence in their quality. This certification shows they aim for excellence, which helps build strong client relationships.

AS9100 certification proves your processes reduce risks and stay reliable. Following these strict rules shows your company values safety and quality. This matters a lot in aerospace, where small mistakes can cause big problems.

Tip: Mention your AS9100 certification when talking to clients. It shows your focus on quality and following rules.

Aerospace clients deal with tough regulations. Partnering with an AS9100 certified maker ensures your products meet these rules. This makes their supply chain easier and boosts their trust in you. For instance, AS9100 certified PCB assembly includes detailed records and tracking, which are key for aerospace standards.

Trust also means showing you improve quality over time. AS9100 certification requires constant checks and bettering processes. This commitment assures clients you deliver top-notch products. It also makes your company a trusted partner in the aerospace field.

Lastly, AS9100 certification helps you shine in a crowded market. Aerospace clients prefer certified companies because they meet global standards. By earning this certification, you not only meet but exceed expectations, building trust and strong partnerships.

Risks of Operating Without AS9100 Certification

Not having AS9100 certification in aerospace can cause big problems. These problems affect safety, performance, and your chance to win contracts. Below are the main challenges you might face.

Safety and Performance Concerns

Without AS9100 certification, your products might not meet strict safety rules. This can lead to serious issues, like unreliable products and higher risks during use. Key safety and performance problems include:

Product Safety: Aerospace parts must follow tough safety rules. Without AS9100, your products might not work safely in complex systems.

Configuration Management: Managing product setups is harder without AS9100’s clear processes. Poor management can cause mistakes and failures.

Counterfeit Parts: Without AS9100 checks, fake parts might enter your supply chain. These parts can harm the safety and performance of your products.

Additional Costs: You may need extra testing to ensure safety. This adds costs and lowers efficiency.

Ignoring these issues can cause recalls, delays, and even accidents. These hurt your reputation and profits.

Note: Aerospace clients care most about safety. Without AS9100, proving your products are safe and reliable is harder.

Loss of Business Opportunities

AS9100 certification is often needed to work with big aerospace companies. Without it, you could lose important business chances. Many clients see certification as a sign of trust and quality. Without it, your company may seem less reliable. Consider these points:

Global Market Access: Certification helps you enter international markets. Without it, growth becomes harder.

Client Trust: Aerospace clients want high-quality products that meet strict rules. Without certification, building trust and partnerships is tough.

Competitive Disadvantage: Certified companies stand out by following industry standards. Uncertified ones may be ignored.

Missing contracts due to no certification can hurt your revenue and market position. In aerospace, certification is a must to stay competitive.

Non-Compliance with Aerospace Regulations

Not following aerospace rules can seriously harm your business. AS9100 certification helps you meet these rules by focusing on tracking, setup management, and record-keeping. Without it, you face these risks:

Aspect | Description |

|---|---|

Certification Requirement | Big aerospace companies often require AS9100 certification to work with them. |

Risks of Non-Compliance | You could lose contracts, face fines, or pay for extra checks. |

Importance of AS9100 | Ensures safety, risk control, and quality for aerospace needs. |

Groups like the DoD, FAA, and NASA support AS9100 certification. While not always required, not having it can hurt your business. You might face fines, more inspections, and a damaged reputation. Also, not meeting rules can delay projects and raise costs, making things harder.

Tip: Getting AS9100 certification shows you care about safety and quality. It makes your business a trusted choice in aerospace.

Damage to Reputation and Client Relationships

In aerospace, a good reputation is very important. Without AS9100 certification, your company might lose trust and respect. Aerospace clients expect high standards for safety and quality. Not having certification suggests your processes may not meet these standards.

If clients think your company is unreliable, they may avoid working with you. This can lead to losing contracts and hurting relationships. For instance, if your products fail safety tests, clients may doubt your ability to deliver good results. Over time, this damages trust and makes it hard to fix your reputation.

Note: Trust takes time to build but can be lost quickly. Without certification, clients may see your company as less reliable in a tough market.

Transparency is also very important. AS9100 certification requires clear records and tracking, which helps clients trust your products. Without this, clients might feel unsure about your processes. This doubt can make them question your focus on safety and quality, further harming your relationships.

Not having certification also makes it harder to get new clients. Many aerospace companies prefer certified suppliers to reduce risks. If your company cannot prove it meets industry rules, potential clients may pick competitors instead. This affects your current business and limits future growth.

Fixing a bad reputation takes a lot of time and work. Once trust is broken, it’s twice as hard to earn back. Getting AS9100 certification shows you care about safety and quality. It proves to clients that you are serious about meeting their needs and expectations.

The AS9100 Certification Process

Getting Ready for Certification

Getting ready for AS9100 certification needs careful planning. First, check your current system to find weak spots. This is called a gap analysis. It shows where you need to improve. Next, make a plan with clear goals, deadlines, and tasks to fix these gaps.

Leaders must be involved and support the process fully. Make sure resources like training and tools are available. Write down all steps, rules, and records to prove you follow AS9100 standards. By doing these steps, you prepare well for certification.

Doing Internal and External Audits

Audits check if you are ready for AS9100 certification. Internal audits help find problems in your system before the main audit. Focus on key areas like risk control, fake part checks, and managing setups. Fix issues to meet AS9100 rules.

External audits are done by experts from a certification group. They check leadership, processes, and safety rules. The table below shows what auditors usually look for:

Component | What Auditors Check |

|---|---|

Leadership Engagement | If leaders are active in improving the system. |

Risk Management | If risks are handled well to avoid problems. |

Counterfeit Part Management | If fake parts are detected and stopped in the supply chain. |

Product Safety Requirements | If safety rules are followed and included in the system. |

By fixing these areas, you show your focus on quality and safety.

Meeting AS9100 Standards

To get AS9100 certification, you must meet strict rules. Certification groups check if your system works well and follows laws. They also do sample checks and give reports on what to fix.

Work on improving your system all the time. Fix any problems quickly and plan to keep following the rules. This helps your system stay strong and meet AS9100 standards. Getting certified shows you are reliable and trusted in the aerospace field.

Keeping Your Certification Over Time

Keeping your AS9100 certification takes ongoing work and careful planning. It’s not something you achieve once but a promise to always meet high standards. To stay compliant with AS9100, you need strong strategies and regular checks.

Build a Strong Quality System: A good system keeps your processes organized and meets AS9100 rules.

Do Regular Internal Checks: These checks find problems early so you can fix them before outside audits.

Think About Risks: Managing risks helps your processes stay strong and ready for challenges.

Work with Reliable Suppliers: Choose suppliers who also follow AS9100 to improve your product quality.

Train Your Team: Teach employees about AS9100 so they know how to follow the rules.

Track Performance with Data: Use numbers to see how you’re doing and spot areas to improve.

Use Digital Tools: Digital systems make it easier to keep records and stay updated.

Always Look for Improvements: Encourage your team to find better ways to work and improve quality.

Tip: Write down everything you do to stay compliant. Good records show your dedication to AS9100 and make future audits easier.

By using these steps, you can keep your certification and stay strong in the aerospace field. Always improving and staying alert will help your processes stay competitive and follow the rules.

AS9100 certification is key for quality and safety in aerospace PCB making. It ensures products follow strict rules, building trust and dependability. Working with AS9100-certified makers gives you reliable and efficient solutions.

Tip: Working with certified suppliers improves your supply chain and shows your business is reliable in aerospace.

Picking AS9100-certified partners helps you stay ahead and deliver great results in this tough industry.

FAQ

What is AS9100 certification, and why does it matter for aerospace PCB assembly?

AS9100 certification is a quality standard made for aerospace. It ensures manufacturers follow strict rules for safety and quality. For aerospace PCB assembly, it helps meet industry rules, lowers risks, and improves product performance.

How does AS9100 certification help aerospace clients?

AS9100 certification builds trust by showing manufacturers follow strict rules. It lowers risks, stops fake parts, and meets aerospace rules. This certification also makes supply chains smoother, helping clients meet their own rules.

How long does it take to get AS9100 certification?

The time depends on how ready your company is. Usually, it takes months to check gaps, fix issues, and pass audits. Companies that prepare well can get certified faster by solving problems early.

Can a company lose its AS9100 certification?

Yes, companies can lose certification if they don’t follow the rules. Regular checks, improving processes, and following AS9100 standards are needed to keep certification and avoid problems.

Is AS9100 certification required for aerospace suppliers?

It’s not always required, but many aerospace clients ask for it. Without it, you might lose chances to work with big companies and struggle in the market.

Tip: If you want to work with top aerospace companies, getting AS9100 certification is a smart move.

See Also

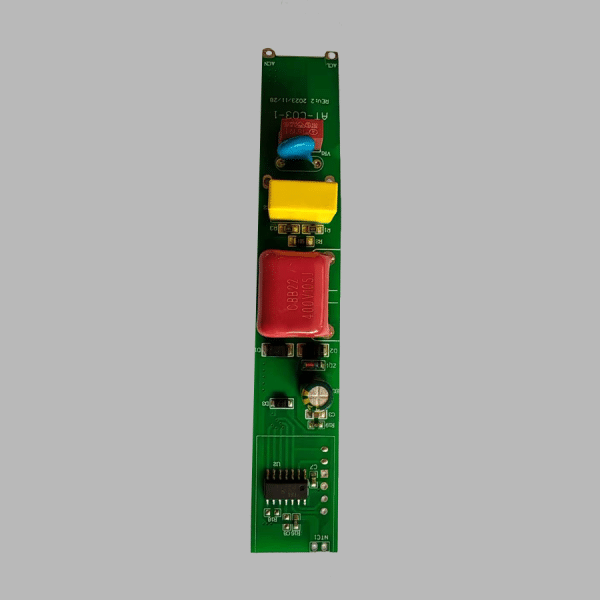

Ensuring PCB and PCBA Quality Through RSJPCBA Methods

IPC-A-610: The Key to High-Quality PCBA Products

Achieving Superior Results Through PCBA Manufacturing Mastery

Innovative AI Technologies Transforming RSJPCBA Design and Assembly

Modern PCB Assembly: Techniques for Precision Soldering Excellence